This series of news round-up gathers the latest news on distribution agreements, certifications, MoU as well as AM initiatives in the US.

Solukon extends its distribution network with new partners in the US

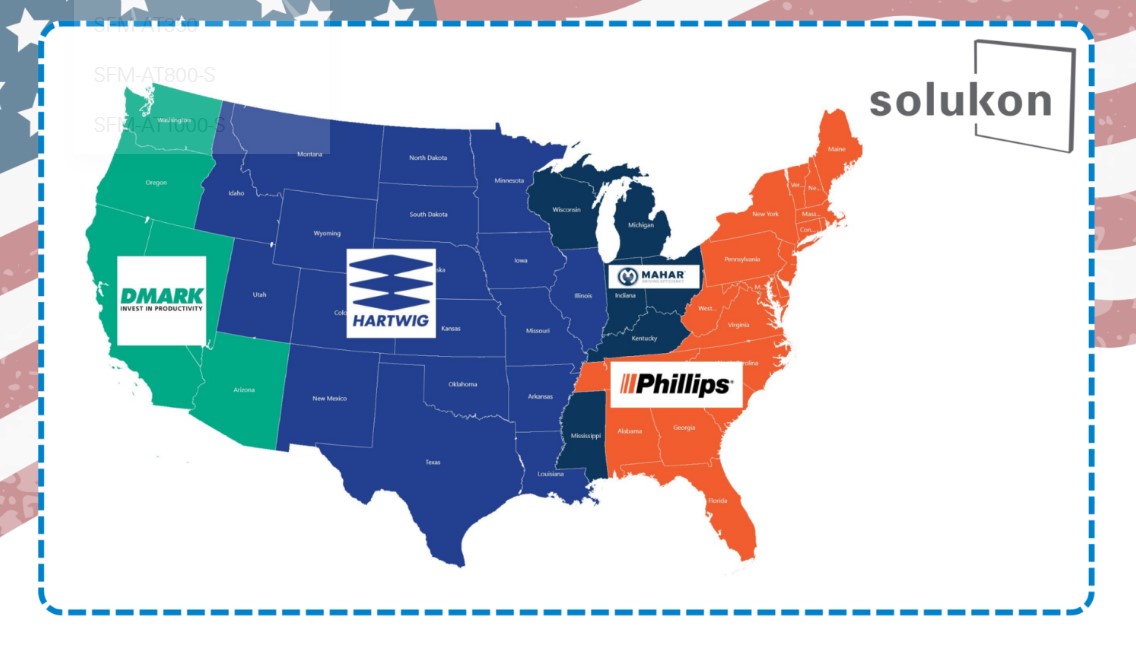

Exhibiting at Rapid+TCT has enabled machine manufacturer Solukon to find new partners that will enable them to expand their presence into the US market. Industrials in North America, could now find the German company’s automated powder machines at five U.S. companies: DMARK Corporation, Hartwig, Inc., MAHAR Tool Supply Company, Inc., Phillips Corporation and BahFed Corp.

Exhibiting at Rapid+TCT has enabled machine manufacturer Solukon to find new partners that will enable them to expand their presence into the US market. Industrials in North America, could now find the German company’s automated powder machines at five U.S. companies: DMARK Corporation, Hartwig, Inc., MAHAR Tool Supply Company, Inc., Phillips Corporation and BahFed Corp.

These distribution partners are respectively responsible for the West Coast region, central US states, the states Wisconsin, Michigan, Indiana, Ohio, Kentucky and Mississippi for MAHAR, the North- and South-East regions as well as governmental regions for BahFed.

These distribution agreements follow the recent move of Solukon into the Swiss Additive Manufacturing market with URMA AG. The past years saw distribution agreements concluded in Europe (e.g. Benelux, UK), Asia-Pacific (e.g. Korea, Australia) and Canada.

“As pioneer and market leader in depowdering it is important to us, that customers and prospect receive the best possible consulting service wherever they are located in the world. Partnering with DMARK, Hartwig, MAHAR, Phillips and BahFed will not only eliminate the time shift effects but gives every US prospect a regional depowdering contact person nearby”, says Michael Sattler at Global Sales Director at Solukon.

Siemens expands focus on AM initiatives in the United States

With the goal of accelerating the transformation of the US Additive Manufacturing (AM) industry, Siemens is building its domestic AM machine builder community.

With the goal of accelerating the transformation of the US Additive Manufacturing (AM) industry, Siemens is building its domestic AM machine builder community.

From its Charlotte Advanced Technology Collaboration Hub (CATCH), located in Charlotte, North Carolina, Siemens will act as an ecosystem platform for machine builders, machine users and additive design engineers alike.

The company currently assists machine builders around the world with motion control, automation hardware, digitalization software and technology capabilities. Siemens can assist AM job shops as well as Tier One production facilities with end-to-end solutions, including product design software, digital twin machine simulation and virtual execution of manufacturing methods, with full data feedback into the design protocol for necessary adjustments, prior to any machine building. “This comprehensive suite of software and motion control hardware offerings makes Siemens a viable partner at every step of the AM process”, according to Steve Vosmik, Head of Siemens Additive Manufacturing in the United States.

Siemens is adding technology to CATCH to incorporate metal binder jet technology through the purchase and installation of an ExOne/Desktop Metal Production System and Meltio Robotic System with the Siemens SINUMERIK RunMyRobot application onboard. SINUMERIK RunMyRobot controls the kinematic path of an industrial robot as it integrates with the CNC machine.

Siemens is also establishing an Additive Manufacturing Advisory Board of renowned industry leaders in AM, drawn from various industries and technical disciplines, to provide the company guidance, as it seeks to support the fast-growing needs of the AM market.

Meltio moves into South Korea through distribution agreement with HDC

Meltio, a laser metal deposition technology manufacturer signed a distribution and sales agreement with HDC for the South Korean market.

As a reminder, Meltio’s metal 3D printing solutions enable industrial applications with a process built around welding wire, described as one of “the safest and most affordable metal feedstock in the market.” As an official sales partner, HDC will focus on building a supportive ecosystem for Meltio’s technology in the South Korean territory, partnering and driving business opportunities.

MakerVerse is granted ISO 9001:2015 Quality Management Certification

MakerVerse, an on-demand manufacturing platform for industrial parts, has received the globally-recognized ISO 9001:2015 certification. The announcement follows the recent series A funding round to scale the activities of its AI-powered on-demand manufacturing platform.

The ISO 9001:2015 certification is an established quality management standard assisting organizations in meeting the needs of their customers and other stakeholders, all while meeting statutory and regulatory requirements related to their products and services. The standard strongly emphasizes customer satisfaction, continuous improvement of processes, and leadership.

Companies that have already received this platform include the likes of 3DEO, Elementum, GF Additive; Wayland Additive, Xometry and much more.

The certification process involved an in-depth valuation of MakerVerse’s quality management system, including its policies, procedures, and processes for ensuring the quality of its parts and services. The certification also involved a thorough audit.

With the ISO 9001:2015 certification obtained, MakerVerse looks forward to continuing to provide high-quality parts and services to its customers.

3D Printer Manufacturer STPL3D signs an MoU with NCAM

Sahajanand Technologies Private Limited (STPL), a 3D printer manufacturer headquartered in Surat, Gujarat has signed a memorandum of understanding (MoU) with the National Centre for Additive Manufacturing (NCAM) based in Hyderabad, Telangana.

Both organizations will be working together for a long-term vision to develop self-sustainable ecosystem of Additive Manufacturing (AM) in the country by enabling the adoption in the industry, prototyping new products, and focusing on new product development, providing access to state of art infrastructure, enabling research and development, and promoting skill development activities for generating quality manpower. The MoU was signed by Rahul Gaywala, CEO of STPL 3D, and Jaspreet Sidhu, CEO of NCAM.

STPL specializes in the development of SLA and FDM 3D printers while, NCAM, established by the Ministry of Electronics and Information Technology, Government of India, and ITE&C Department, Government of Telangana, aims to create an ecosystem for product innovation in India. The organization focuses on research, design, development, and testing, through the collaborative efforts of academia, industry, and government utilising the disruptive technology of Additive Manufacturing.

Through this MoU, both organization will facilitate the adoption of AM in the industry by prototyping new products and focussing on the development of new products, providing access to infrastructure, enabling research and development, and promoting skill development activities to produce high-quality labour.

They will also promote ‘Made in India’ technologies and products in Indian industries as well as in Indian academic institutions and support the growth of local industries in the AM space. The MoU also calls for the creation of a national platform to showcase Indian AM technologies and products.

Remember, you can post job opportunities in the AM Industry on 3D ADEPT Media or look for a job via our job board. Make sure to follow us on our social networks and subscribe to our weekly newsletter: Facebook, Twitter, LinkedIn & Instagram ! If you want to be featured in the next issue of our digital magazine or if you hear a story that needs to be heard, make sure you send it to contact@3dadept.com