In collaboration with Parastruct GmbH, a company that specializes in converting mineral and biogenic waste streams into circular materials and components, 3D printer manufacturer voxeljet used its Binder Jetting 3D printing technology to process recyclable residual materials from the construction industry.

The material tested was the Ecomould material set from Parastruct GmbH – it was made up of biogenic production residues from the construction industry and a mineral binder.

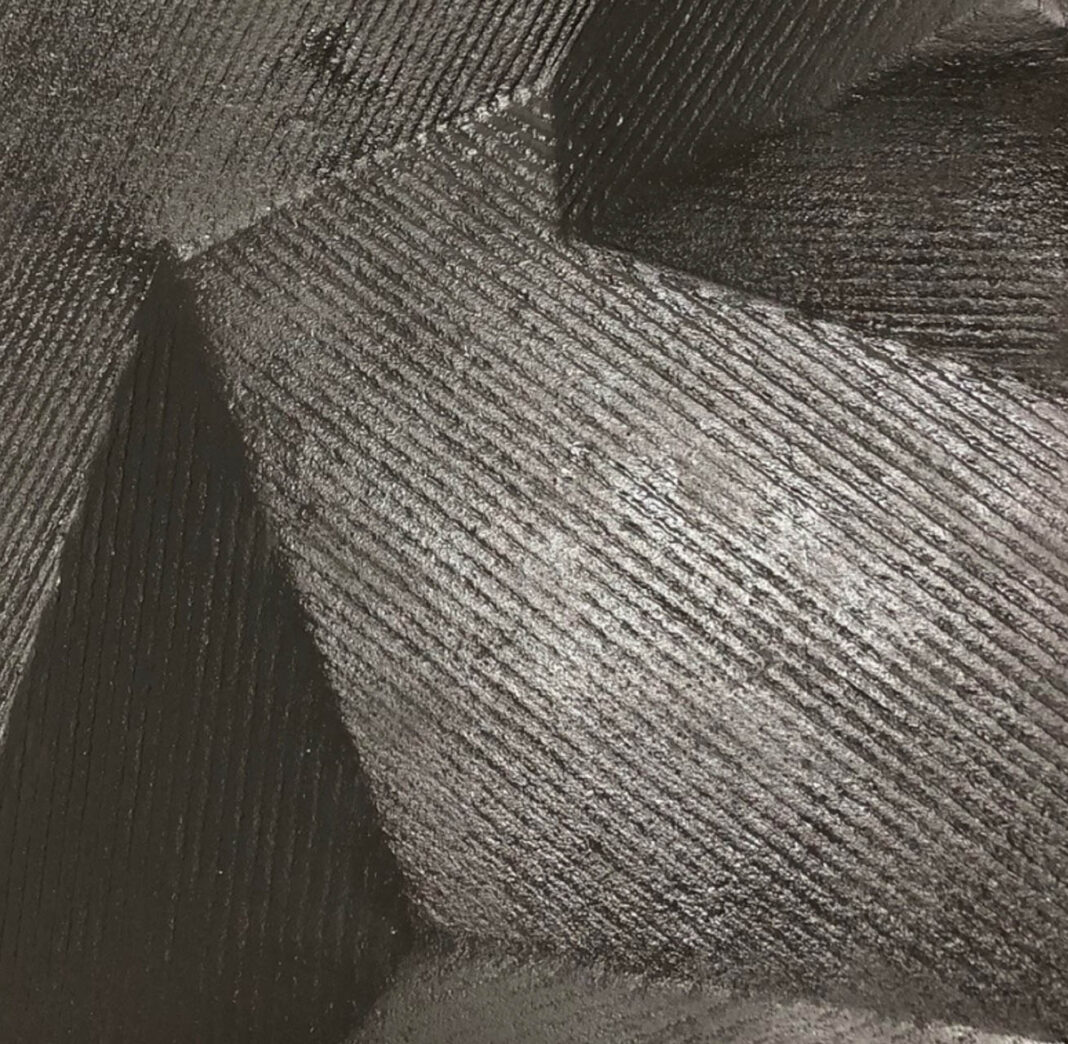

With binder jetting, Ecomould can be used to produce molded parts that are suitable for the cold casting of concrete and ceramics for interior design objects or for laminating processes. The Ecomould material was tested on a VX200 from voxeljet – a 3D printing system specially developed for research and development purposes, a press release reads.

Due to an open source strategy, the printing parameters of voxeljet machines can be adapted to different material sets. The machine manufacturer explains that Ecomould-produced molds can be shredded and reused as particle material in 3D printing. A plastic coating can be applied as a finish, which is removable at the end of its service life. This second use of Ecomould material reduces the carbon footprint even further.

The successful collaboration presents a potential for the material recycling market which is expected to grow at an annual rate of 7-9% until 2025. With 3D printing, Parastruct can reintroduce unused mineral materials, such as production waste from the construction industry, and biogenic resources, such as wood flour or sawdust, back into the value-creation process.

voxeljet is now looking for companies that will be interested in joining forces for a more sustainable construction industry.

Remember, you can post job opportunities in the AM Industry on 3D ADEPT Media free of charge or look for a job via our job board. Make sure to follow us on our social networks and subscribe to our weekly newsletter : Facebook, Twitter, LinkedIn & Instagram ! If you want to be featured in the next issue of our digital magazine or if you hear a story that needs to be heard, make sure to send it to contact@3dadept.com.