The high volume manufacturing needs of the AM industry is being fulfilled courtesy a 3D printer introduced by metal additive manufacturing company Holo at Formnext this year, adding to other recent 3D printers improvement announcement made by AM companies

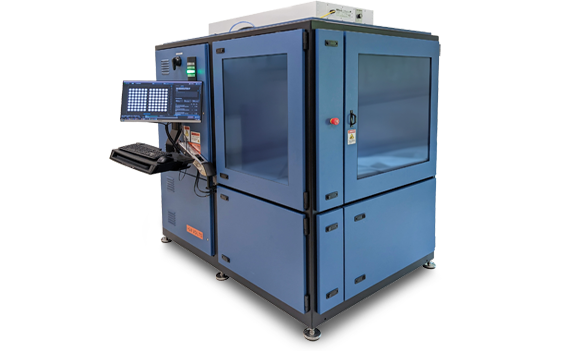

The AM company has announced that they are opening up their H200 production printer for commercial use. With the help of this 3D printer, the AM industry can deliver better accuracy and surface finishing in the 3D printed parts.

Main features of the H200 3D Printer

The H200 production is equipped with Holo’s PureForm™ lithographic high resolution printing approach which enables it to produce precise 3D printed parts at a cost point. This has economic advantage over a single prototype as it can full-scale production runs of millions.

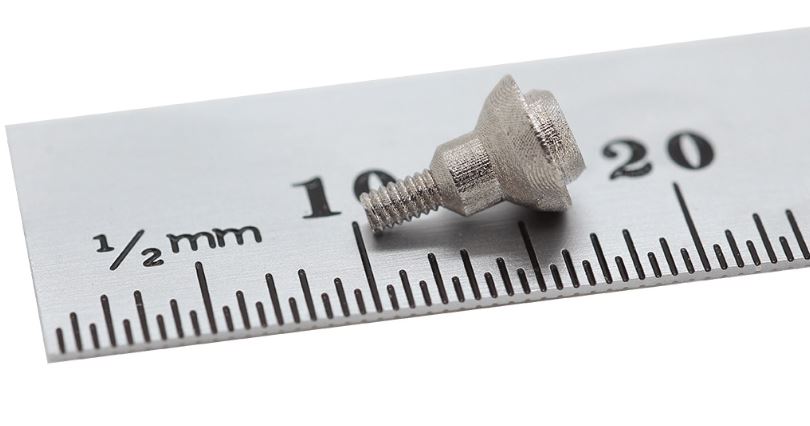

In the last nine months, Holo supplied complex metal 3D printed parts which have 50µm detail and maintain tolerances within +/-25µm or +/-0.1% on a dimension.

The PureForm™ technology makes the end-use AM parts match the surface smoothness of commercial MIM parts, having a roughness of 1-3µm Ra. This eliminates the cost of additional machining and polishing needed in other metal AM technologies.

Speaking of the new printer at Formnext, Holo Co-founder Arian Aghababaie said: “True to CAD™ from Holo’s technology means that our H200 system produces MIM-quality parts without the mold. For most applications, our technology does not require parts to go through any post-machining or polishing; it sinters parts to spec for a first-time-right approach suited for demanding, high-volume end-use applications”.

The H200 3D printer creates 3D printed parts of complex geometries like dental abutments at a rapid rate of 8 secs/part with 200µm thread pitch.This is done while maintaining tight tolerances across part runs of hundreds of parts.

The company’s PureForm™ commercial 3D printing material includes stainless steel grades 17-4PH and 316L, along with pure copper. Holo has further extended the portfolio to include Inconel and Ti-64 material. All the 3D printing materials supplied by Holo fulfil MPIF-35 specifications.

Holo’s H200 3D printer has the following specifications

- Build volume up to 244 x 195 x 200 mm

- Resolution down to 50µm features

- Onboard software

- Compatible with standard MIM furnaces, 240V

- No hazardous powder handling / inert atmosphere setup required

“Production volumes of parts in fields like surgical instruments will be within reach, finally fulfilling the promise of additive manufacturing as a scalable, production-ready suite”, said Holo CEO Hal Zarem.

Remember, you can post job opportunities in the AM Industry on 3D ADEPT Media free of charge or look for a job via our job board. Make sure to follow us on our social networks and subscribe to our weekly newsletter : Facebook, Twitter, LinkedIn & Instagram ! If you want to be featured in the next issue of our digital magazine or if you hear a story that needs to be heard, make sure to send it to contact@3dadept.com