Designer and supplier of nuclear equipment Framatome first appeared on our radar two years ago. It had just 3D printed uranium-molybdenum and uranium-silicon objects. Fast forward to today: the company announces the successful installation of a 3D printed, stainless steel fuel component at the Forsmark Nuclear Power Plant, operated by Vattenfall in Sweden.

The completion of this project is worth highlighting when we know that the nuclear industry is one of the most complex ones when it comes to integrating Additive Manufacturing. So far, successful applications publicly announced in the field include 3D printed nuclear reactor components created by Framatome in collaboration with Oak Ridge National Laboratory (ORNL) and two successful applications completed by Westinghouse.

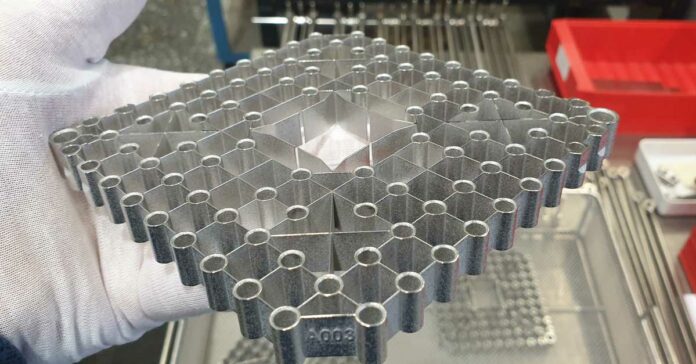

In this specific case, the 3D printed part is an upper tie plate grid, a non-structural weight-bearing component that secures fuel rods and retains larger debris from entering the fuel assembly from the top. Upper tie plate grids are easily inspected, and samples are accessible for qualifying this new manufacturing process for in-reactor use as needed.

“The safe operation of fuel assemblies is key to Vattenfall,” said Ella Ekeroth at Vattenfall Nuclear Fuel AB. “Along with this basic principle, our contributions to the development of efficient and reliable manufacturing processes are in the best interest of the entire nuclear industry. The overall goal of these activities is to maintain and further enhance safety and enable economically viable long term operations.”

These parts are usually manufactured via laser welding, using stamped comb-like sheets that require additional manufacturing steps and operator oversight. Information related to how much time and costs AM has enabled to save, has not been given. However, the company confirms that AM did streamline the manufacturing process and increased design options for enhanced functionality and improved performance.

It’s been seven years that Framatome has been exploring AM for nuclear fuel with a focus on stainless steel and nickel-based alloy fuel assembly components, and so far, the company achieves striking milestones that show others the path to follow.

Listen to this Additive Talks session: How has AM advanced in the nuclear industry? Opportunities & Challenges.

Remember, you can post job opportunities in the AM Industry on 3D ADEPT Media free of charge or look for a job via our job board. Make sure to follow us on our social networks and subscribe to our weekly newsletter : Facebook, Twitter, LinkedIn & Instagram ! If you want to be featured in the next issue of our digital magazine or if you hear a story that needs to be heard, make sure to send it to contact@3dadept.com