Despite the numerous advantages of copper, one of the main constraints for operators who process this material is its high laser reflectance rate which makes it difficult for the laser to continuously and regularly melt pure copper powder, resulting this way in issues such as interface failure and internal holes.

As we saw in a recent dossier of 3D ADEPT Mag, to address this issue, some metal 3D printer manufacturers have integrated into their platforms build parameters, scanning and processing parameters that can reduce this reflectivity issue. Another solution might be to leverage a dedicated 3D printable material.

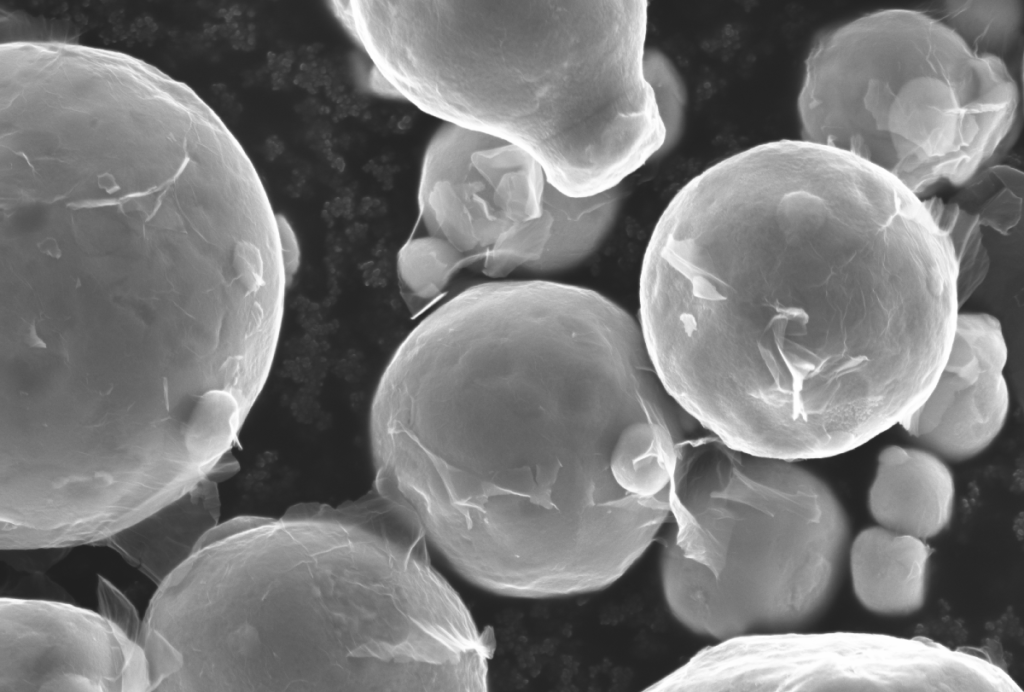

The solution has been explored by researchers at Uppsala University, in collaboration with Swedish graphene materials company Graphmatech. To demonstrate the printability of copper for laser additive manufacturing, the team of scientists used Graphmatech’s patented graphene technology to coat copper powder, the ultimate goal being to reduce the material’s reflectivity and achieve more dense printed parts.

“By modifying the surface of the copper powder using Graphmatech’s patented graphene technology, we successfully reduced the reflectance by up to 67%”, explains Graphmatech CEO Dr Mamoun Taher.

According to Taher, the graphene incorporated also survived the printing process to positively impact the density of the printed copper-graphene parts, significantly reducing their porosity.

“The new process developed to coat metal powder with graphene opens up very interesting perspectives for the design of new materials in various applications”, states Professor Jansson from the research group at Ångström Laboratory, Uppsala University.

The Swiss company has already made significant areas for improvement in other graphene-metal composites and coated powders for additive manufacturing. Due to the potential for graphene in enhancing the processability of powders and the properties of printed parts, the main sectors that would benefit from this solution are the e-mobility, electronics and defence industries.

Remember, you can post job opportunities in the AM Industry on 3D ADEPT Media free of charge or look for a job via our job board. Make sure to follow us on our social networks and subscribe to our weekly newsletter : Facebook, Twitter, LinkedIn & Instagram ! If you want to be featured in the next issue of our digital magazine or if you hear a story that needs to be heard, make sure to send it to contact@3dadept.com