Launched at Formnext, and developed by ULT AG, the AMF 200 system is a flexible process gas cleaning designed for metal 3D printing, LPBF – laser powder bed fusion especially.

In case you are not familiar with them, ULT is a company that specializes in extraction, filtration, and air-drying technology and that brings two decades of experience in the field of additive manufacturing.

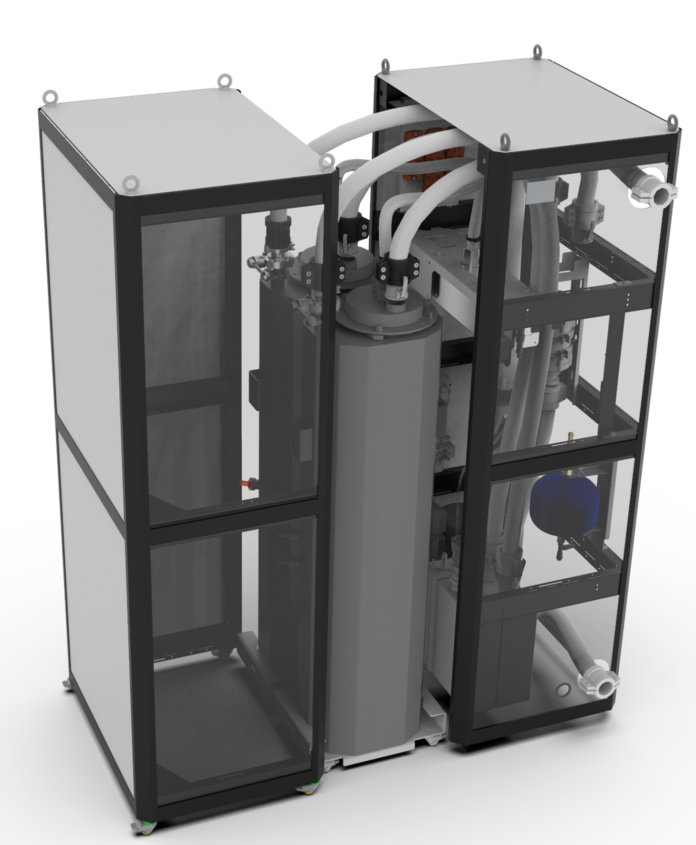

The AMF 200 system is a modular, open and, thanks to the use of standard components, cost-optimized extraction and filtration system for metal-based additive manufacturing systems of all sizes.

It offers a volume flow of up to 200 m³/h at a vacuum of 10,500 Pa (N2, 50°C) / 15,000 Pa (Ar, 50°C). However, the AMF 200 can be variably adapted to higher or lower gas flows – regardless of the provider and the volume of the 3D printer.

In addition to the small footprint of 800×1200 mm and extremely simple operation, the contamination-free filter and powder handling is another decisive benefit of the AFM 200. Employees never come into contact with powders or condensates and are therefore protected from skin irritation or allergic reactions.

The system can be operated both as a slave with an I/O system and as an independent machine run by a specially configured controller.

Additional features, such as automated filter cleaning, the use of a side channel compressor with mounted frequency converter or the use of various sensors (differential pressure filter stages, filter cell fill level, oxygen, volume flow, temperature) round off the overall package as a sustainable and effective solution for metal additive manufacturing.

Remember, you can post job opportunities in the AM Industry on 3D ADEPT Media free of charge or look for a job via our job board. Make sure to follow us on our social networks and subscribe to our weekly newsletter : Facebook, Twitter, LinkedIn & Instagram ! If you want to be featured in the next issue of our digital magazine or if you hear a story that needs to be heard, make sure to send it to contact@3dadept.com.