Developer of wire-laser metal deposition technology, Meltio has recently unveiled Meltio Space software, a new slicer that will increase the reliability of metal part manufacturing.

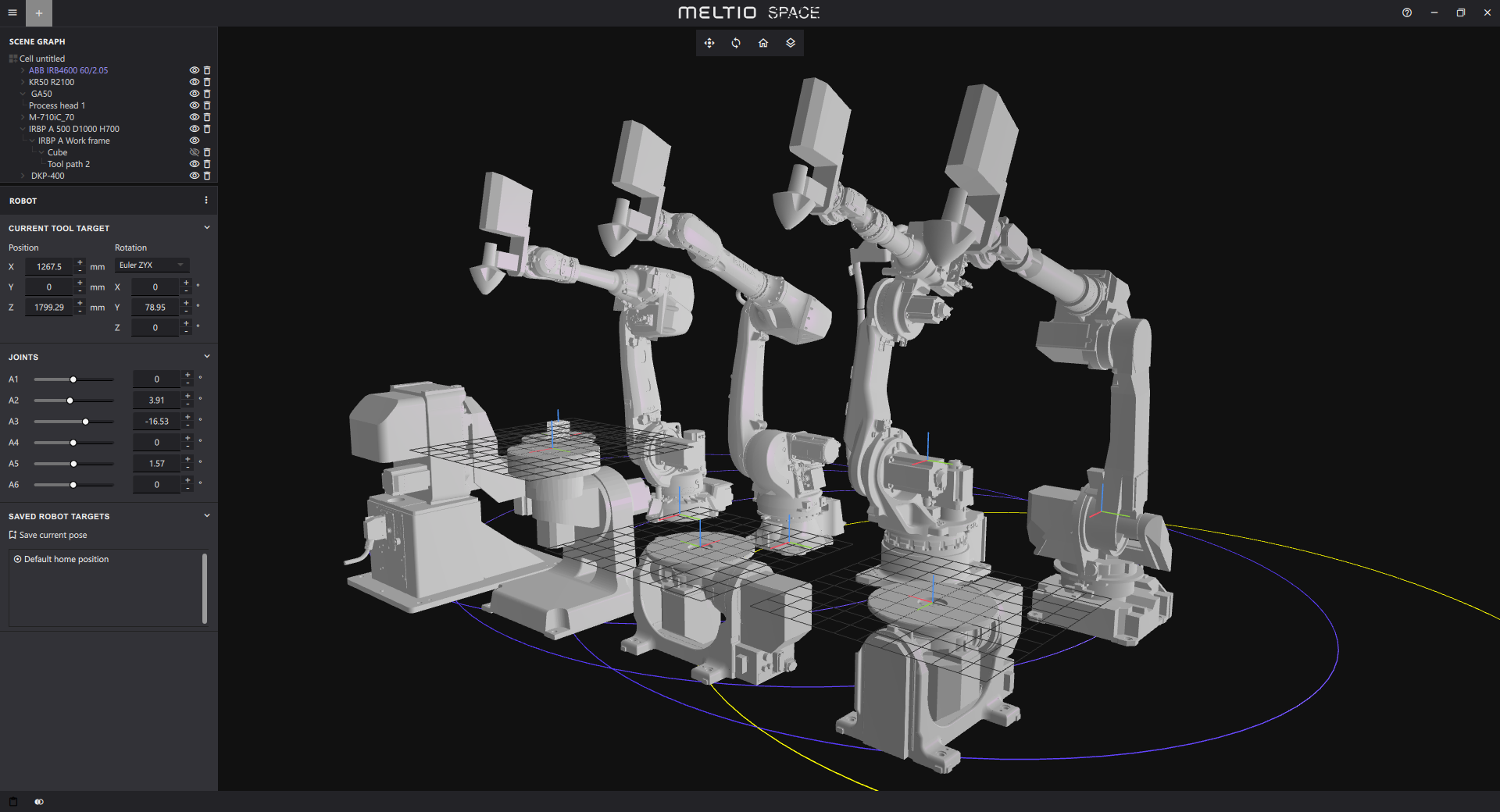

The toolpath generator software is designed for the Meltio Engine Robot Integration with an easy-to-use interface for planar, non-planar, and variable extrusion toolpaths. It also includes 2-axis workpiece positioner interpolation, kinematics simulation, collisions check, and cell configuration.

With the goal of 3D printing by breaking free from the limitations of traditional 3-axis systems, Meltio Space takes a step further and expands the possibilities by incorporating advanced robotic manipulation capabilities.

Enhancing robotic AM

Enhancing robotic AM

With its intuitive design, no expertise in robotics or programming is required to work with Meltio Space. The software goes beyond the constraints of traditional 3-axis systems with its integration of 6-axis robotic manipulator and 2-axis workpiece positioners.

Meltio Engine Product Manager, Alejandro Nieto explains that Meltio Space includes preset and recommended material profiles and 3D printing parameters and a series of specific processors for robot arms from ABB, Kuka, Fanuc, and Yaskawa including collision detection, and simulation. Industrial applications are improved thanks to the new Meltio Space software in which the learning curve of their Engine integrators was very low because they depended on third-party software and those developers do not have the knowledge that they can have in Meltio of the Meltio Engine.

“So the main goal of our technology is to give the most efficient tool that allows the industry the most of the applications they need to manufacture metal parts with our wire-laser technology,” he adds.

The advanced robot slicer simplifies the integration of the most popular robotic brands with a built-in robot library and post-processors for ABB, Kuka, FANUC, and Yaskawa. Best part of it is that the Meltio Space robot slicer includes these features at no extra cost. Moreover, Meltio Space removes complexity in the 3D printing workflow, making it accessible to industrial users of all levels.

This product offers custom-developed Meltio print profiles for the extensive Meltio materials portfolio. It also ensures low capital and running costs, which are further reflected in the software licensing model.

Meltio Space robot slicer employs a virtual model of the real robot movement. This advanced feature allows users to simulate the kinematics of the robot, ensuring accurate and precise printing. Additionally, the slicer performs collision checks with the part being printed, minimizing the risk of errors or damage during the additive manufacturing process.

Remember, you can post free of charge job opportunities in the AM Industry on 3D ADEPT Media or look for a job via our job board. Make sure to follow us on our social networks and subscribe to our weekly newsletter : Facebook, Twitter, LinkedIn & Instagram ! If you want to be featured in the next issue of our digital magazine or if you hear a story that needs to be heard, make sure to send it to contact@3dadept.com