Manufacturer of wire-laser metal deposition system Meltio announces the launch of a new wire-laser system. Named Meltio M600, the new metal 3D printer would be the ideal point of entry for the machine shop and would require minimal operator interaction for autonomous production.

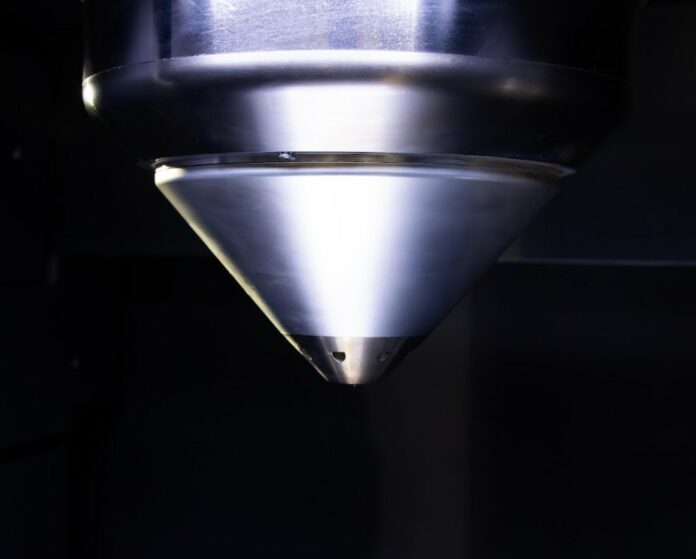

It features a Blue Laser deposition head and its lasers would improve energy absorption and printing efficiency across the metal spectrum while opening up new material possibilities. That head is laden with new and improved sensor solutions for monitoring the printing process, which makes printing more reliable.

In addition to the minimum operator interaction, the industrial 3D printer would bring 4 main advantages:

In addition to the minimum operator interaction, the industrial 3D printer would bring 4 main advantages:

- It uses welding wire as its feedstock compared to the much more common powder-based 3D printer. Having a wire material that is much cheaper, safe to handle and that does not risk contamination of your CNC Machines is a huge advantage for industrial integration.

- Materials properties that result from the manufacturing process are comparable with parts manufactured conventionally.

- Our newly developed Blue Laser deposition head increases printing speed while reducing energy consumption thanks to the increased absorption of the short wavelength light compared to most industrial lasers which emit near-infrared light. This advantage is multiplied for reflective materials such as copper and aluminum alloys where near-infrared lasers lead to unsatisfactory results. Combining this with the fully inert workspace, the Meltio M600 can process a large range of materials efficiently while producing parts with exceptional properties.

- The complete system has been designed to easily interface in the same industrial environment with CNC machines, it features a built-in 3-axis touch probe and supports various types of work holding solutions which means you can also add features to or repair existing parts rather than printing them entirely.

These features make the 3D printer an interesting production candidate for automotive, aerospace, oil & gas, mining, and defense.

Lukas Hoppe, Research & Development Director at Meltio states: “The Meltio M600 for us was really the next logical step on our continuous journey towards mass adoption of Wire-Laser DED, the process all Meltio systems are based on. We began this work in earnest in 2019 when we started to leave the prototyping space with the launch of the Meltio M450. After learning from and improving the technology for three years, the time was finally ripe for us to work on the next system. Our goal with the Meltio M600 was to strike the right balance between machine size, cost, and productivity while being uncompromising on quality, reliability, and ease of use. To achieve this, (…) we developed every single part of the machine from scratch to take the technology to the next level, based on the learnings of having manufactured and installed over 300 Laser DED machines.”

This announcement follows a recent partnership of Meltio with One Off Robotics.

Remember, you can post job opportunities in the AM Industry on 3D ADEPT Media for free or look for a job via our job board. Make sure to follow us on our social networks and subscribe to our weekly newsletter: Facebook, Twitter, LinkedIn & Instagram ! If you want to be featured in the next issue of our digital magazine or if you hear a story that needs to be heard, make sure you send it to contact@3dadept.com