Meltio, a developer of DED 3D printing technology, has launched the Meltio Robot Cell, a metal Additive Manufacturing solution designed to enhance the use of an industrial robotic arm.

Ready to be used for robotic metal 3D printing, Meltio Robot Cell is designed as a plug & play system, with a single electrical power supply and a single inert gas supply. As most equipment, it should be used in a highly controlled environment: this means it can neither be used in an outdoor environment, nor exposed to the sun.

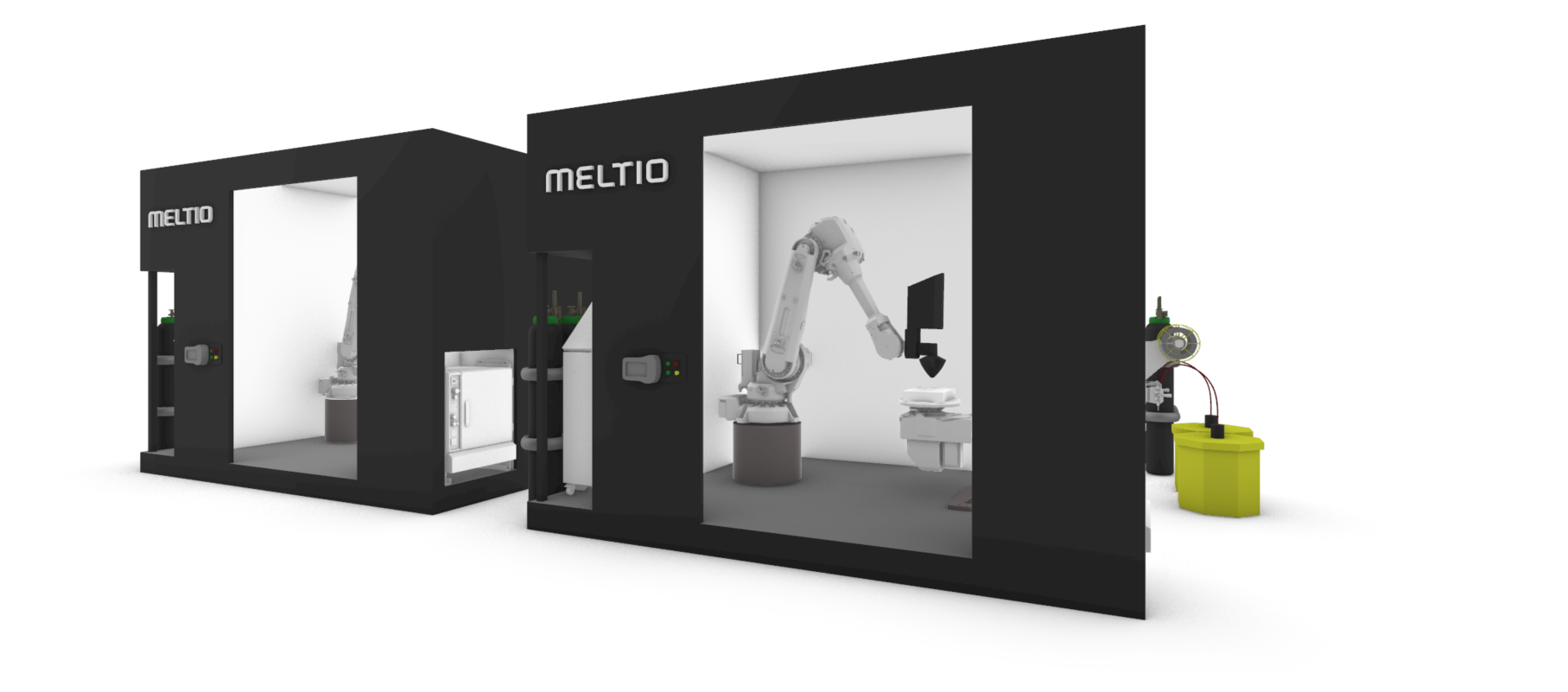

The robot and the positioner can be installed on a self-supporting platform, laser safe enclosure together with Meltio Engine, Meltio Space and accessories, the company explains.

The new system enables standard metal 3D printing starting from a build plate in a factory as well as part repair. The compatibility with open hardware platforms makes it possible to integrate a metal 3D print head into any brand of robotic arm. As a matter of fact, the Robot Cell is certified and tested to operate with an ABB robotic arm as standard configuration.

Meltio Engine Product Manager, Alejandro Nieto explains that Meltio’s main commitment with the launch of Meltio Robot Cell is to offer all types of industries the ability to manage the entire manufacturing process using their metal 3D printing technology. The latter consists therefore of a Meltio head integrated in a robotic arm and in a safe environment.

“This new hardware system allows the customer to receive a ready to use cell for robotic metal 3D printing, removing the integration process and long assembly lead times. The Meltio Robot Cell has a specific area for every supply the cell requires on a daily basis, only connecting to the inert gas and electric supply is enough to start manufacturing.

Meltio Robot Cell also provides the industrial customer with a working protocol. Relative to existing offerings in the market today, the Meltio Robot Cell is very competitively priced and its price is below 300,000 dollars ex works. The cost of the solution is also competitive when compared with thermoplastic and concrete 3D printing systems as seen in other sectors that demand 3D printing for structural parts. This cell has the possibility to be delivered with other robot brands on the market to be more responsive to customers in terms of availability and technical capability. Meltio Robot Cell is compatible with the open hardware platform that allows Meltio to integrate our metal 3D printing head on any brand of robotic arms,” he concludes.

Remember, you can post free of charge job opportunities in the AM Industry on 3D ADEPT Media or look for a job via our job board. Make sure to follow us on our social networks and subscribe to our weekly newsletter : Facebook, Twitter, LinkedIn & Instagram ! If you want to be featured in the next issue of our digital magazine or if you hear a story that needs to be heard, make sure to send it to contact@3dadept.com