Belgian 3D printing giant Materialise has recently launched a software solution that can optimize data and build preparation for laser powder bed fusion (LPBF) systems. Named e-Stage for Metal+, the software solution uses physics-based modeling to automate the support structure generation.

Given the fact that LPBF accounts for over 52% of the industry’s global revenue (figures of 2022), it makes sense to see a continuous focus on this process to reduce the manufacturing cost associated with this process.

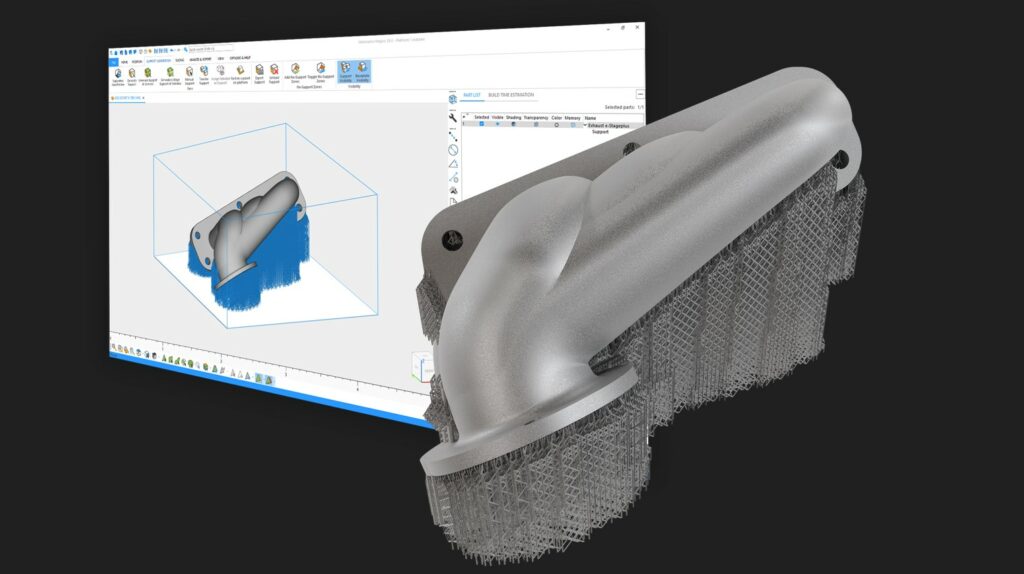

e-Stage for Metal+ leverages physics-based modeling to calculate where deformations during the 3D printing process will occur and automatically generates needle-thin and cone supports where needed. Combining the two support types optimizes stability and heat distribution during the 3D printing process, helping to avoid part deformation while reducing post-processing efforts. This removes the compromise between part quality and overall production costs, offering companies a fresh perspective on their complete LPBF process by making it more economically viable and straightforward to adopt. Automated tools like e-Stage for Metal+ lower the learning curve, allowing users to connect the software to any machine and quickly optimize support generation; Materialise explains.

“Metal AM users tend to overload parts with support structures during manual data preparation,” explains Ian O’Loughlin, Metal Practice Lead at Materialise. “They want to avoid defects and the costs associated with reprinting the parts. That’s why intelligent tools like e-Stage for Metal+ are crucial. Automating support structure generation at the sweet spot of printability and required supports saves time, material, and post-processing costs.”

e-Stage for Metal+ is a module for Magics, Materialise’s data and build preparation software and core element of its 3D Print Suite. As a reminder, Magics is a technology-neutral software offering compatibility with nearly all import file formats and connectivity to all major 3D printing technologies. It provides users with advanced control and automation for their workflows.

Remember, you can post job opportunities in the AM Industry on 3D ADEPT Media free of charge or look for a job via our job board. Make sure to follow us on our social networks and subscribe to our weekly newsletter : Facebook, Twitter, LinkedIn & Instagram ! If you want to be featured in the next issue of our digital magazine or if you hear a story that needs to be heard, make sure you send it to contact@3dadept.com