Construction company Abyan has recently built 3D-printed large water tanks for Kuwait United Poultry Company. Built to provide drinking water to chickens on a farm, the tanks are described as a “world’s first” and measure 4,5m in height and 7m in diameter.

They were 3D printed with real C40/50 concrete mixed on-site using the D.fab solution in just 5 days using a COBOD 3D printer and only contained macro fibers for the reinforcement of the tank walls and no traditional reinforcement meshes.

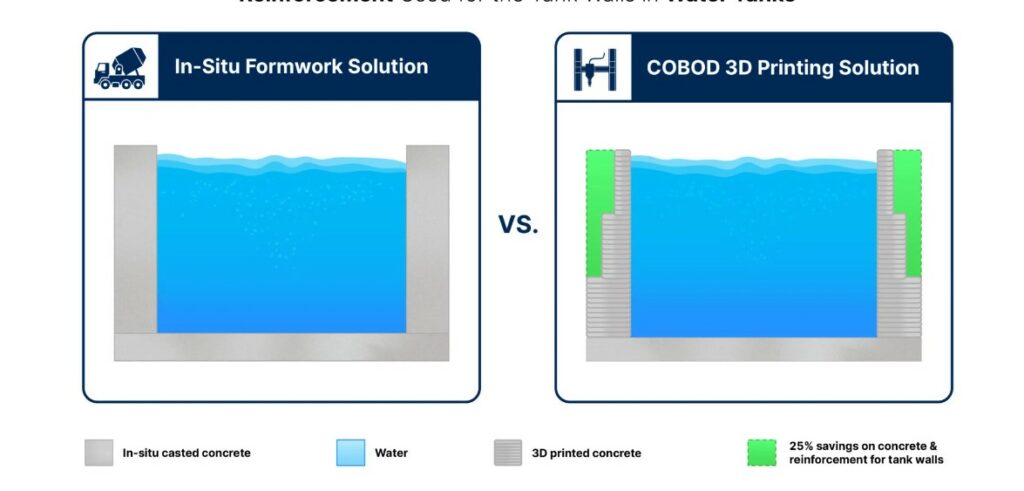

When constructing large tanks with the traditional method of formwork and concrete, the tank walls must be the same thickness from top to bottom because formwork can not vary the thickness in height. 3D construction printing does not have this limitation, allowing structural engineers to adjust the wall thickness where needed. Since gravity and water pressure make the bottom of the tank experience more stress, those areas need thicker walls. With 3D printing, the bottom walls can be made thicker and the upper walls thinner, saving materials and making the construction of the tanks both more economical and sustainable.

This structural engineering principle is reflected in the below diagram, showing that the tank in Kuwait had 40cm wall thickness at the bottom part, 30cm in the middle part, and 20cm at the top part, leading to 25% less concrete and reinforcement have been used for the walls, compared to if the tank had been cast with 40cm walls all the way up.

“When all of our calculations showed that with 0,95% macro fibers in the concrete, we could remove all hard reinforcement of the tank walls, we were keen to prove this new design concept with a real-life project”, CEO and co-founder of Abyan, Dr. Ahmad Al-Nassem said.

Remember, you can post job opportunities in the AM Industry on 3D ADEPT Media free of charge or look for a job via our job board. Make sure to follow us on our social networks and subscribe to our weekly newsletter : Facebook, Twitter, LinkedIn & ! If you want to be featured in the next issue of our digital magazine or if you hear a story that needs to be heard, make sure to send it to contact@3dadept.com