The use of 3D printing in the jewelry industry is not that new. As a matter of fact, we have already highlighted several examples on this platform. However, the use of Windform® GT – a composite material that can be processed via Selective Laser Sintering (Laser-Powder Bed Fusion technology) – in the fashion industry and by jewelry brand company Eternha is relatively new. So far, applications achieved with this type of material have already been seen in harsh environments, motorsports or aerospace industries.

Stefano Massimiliano Marangoni and Chiara Cistriani founded Eternha two years ago and opened a store on June 25, 2022. They combine the traditional materials of the jewelry industry and craftsmanship (natural hard stones and/or precious and non-precious metals) with a polyamide-based composite, glass fiber reinforced developed by technology company CRP Technology.

“It is a brand new project, never realized before” Stefano Massimiliano Marangoni and Chiara Cistriani say. “50% of our investments are focused on product quality. The rest is innovation, eco-sustainability and the search for harmony between materials and colors. Our purpose has always been to realize high-quality jewels. Once the level of materials was fixed, we wanted to be innovative; so we decided to insert in our creations some elements made of a hi-tech material that, on the one hand, would provide a precise identity to our bracelets, and on the other hand, allow anyone to wear something unusual for the fashion world.”

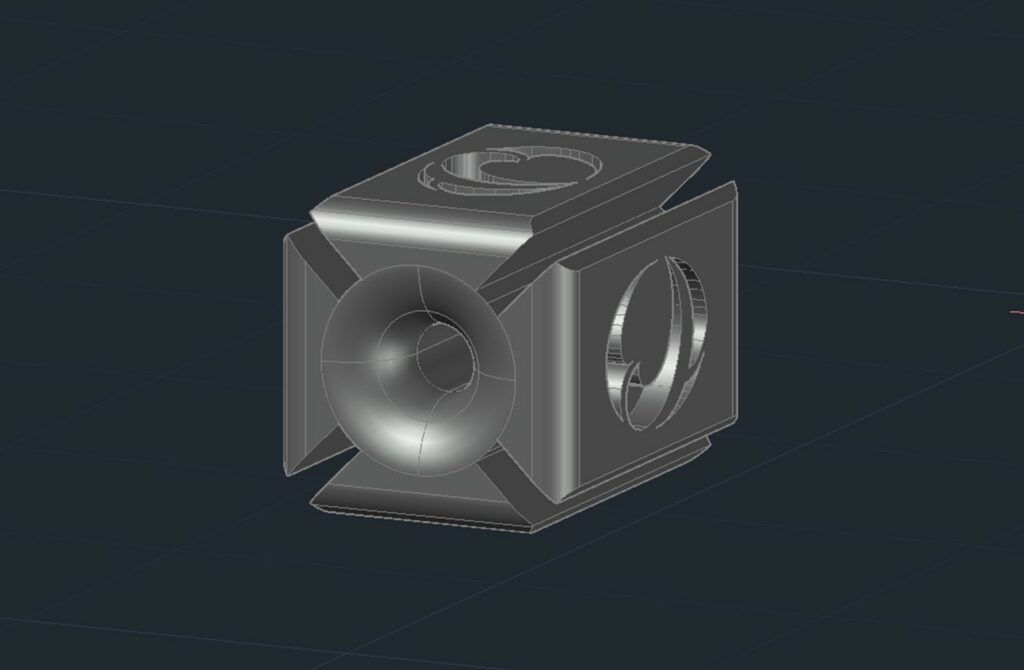

Windform® GT has been used to manufacture some elements for Eternha Men’s bracelets Aquilha, Falcho, Lupho and Cobrha.

“They are small elements – Stefano specifies – approximately 10-12 mm as a maximum size. Shapes vary from parallelepiped to sphere and cylinder, with different graphic elaborations. And, in one case, with the engraving of our company logo.”

“Given the very small shapes, we had to abandon some ideas and adapt others. But there is no compromise when it comes the quality. We wanted the top of the hi-tech range, and we got it with the Windform® GT composite material”, Chiara states.

Windform® GT is a highly versatile composite material in terms of performance and aesthetic appeal. In fact, it combines excellent characteristics of elasticity, ductility and impact resistance, with a deep lustrous finish after hand polishing. It is also not electrically conductive, it is resistant to the absorption of moisture and liquids, and is approved for skin contact, a press release reads.

“We wanted to include in our creations one or more elements made of a material used to manufacture advanced, functional applications; a material capable of attracting customers for its intrinsic meaning and for the suggestions it evokes, rather than for its excellent mechanical characteristics. We want to give ordinary people the opportunity to wear “a piece” of technology, which will travel in Space, will race in Motorsports competions, will improve the quality of life in the applications to come”, Massimiliano Marangoni concludes.

Remember, you can post job opportunities in the AM Industry on 3D ADEPT Media free of charge or look for a job via our job board. Make sure to follow us on our social networks and subscribe to our weekly newsletter : Facebook, Twitter, LinkedIn & Instagram ! If you want to be featured in the next issue of our digital magazine or if you hear a story that needs to be heard, make sure you send it to contact@3dadept.com