Elkem, one of the main providers of advanced silicon-based materials, has developed a new specialized iron silicon powder, which may allow 3D printing of components for electrical motors.

The development was made as part of an EU-funded project called SOMA together with research- and customer partners, such as VTT (coordinator), Siemens, Stellantis and Gemmate Technologies. SOMA stands for “lightweight solutions for e-mobility by AM for soft magnetic alloys.” The 3-year project, which started 01.01.2021, was supported by EIT Raw Materials, funded by the EU with a total project budget of just over € 5.6 M.

In general, electrical motors are generally made by cutting and molding pieces from a metal sheet. When 3D printing is involved, copper or metallic materials are often the materials chosen for production.

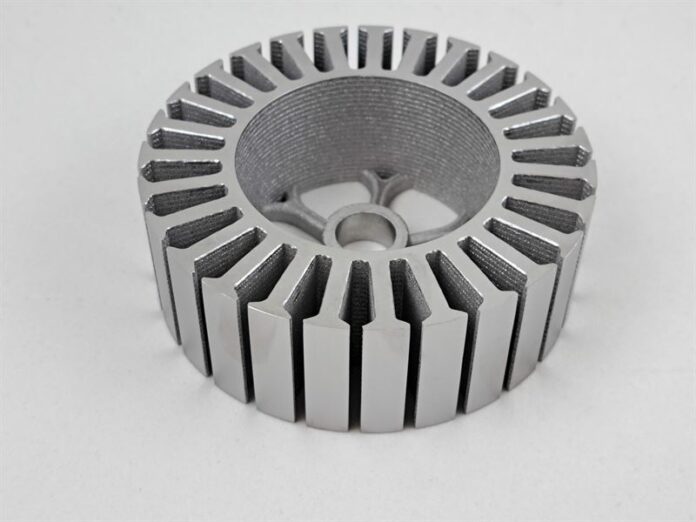

In this specific case, the powder is so-called soft magnetic, meaning that it is easy to magnetize and de-magnetize, which is important in electrical motors. It is produced in a small-scale pilot atomiser, located in Kristiansand at the Future Materials, Norwegian Catapult Centre. The powder has been used to 3D-print components for evaluation of the quality and manufacturing of demo devices. The 3D printing and part qualification has been done at VTT in Finland and Siemens in Germany, Elkem explains.

“We have successfully created a new specialized powder with good printability based on silicon-steel (with additives). 3D-printed components show enhanced ductility and competitive magnetic properties,” said Tomi Lindroos at VTT.

The final use case was to produce a motor for an electric scooter. The use-case was supported by modelling carried out by Gemmate-Technologies and VTT giving more novel design opportunities for electrical motor components.

“The powder developed in the SOMA project will now be introduced to the market by Elkem for evaluating the product for future commercial production. The product is currently available in small test volumes,” said Jan Ove Odden, Project leader at Elkem.

If you’re a regular reader of 3D ADEPT Media, you may know that companies like Additive Drives GmbH are demonstrating that there is a business model for Additive Manufacturing in the electric motor market but the challenges are often the same: 3D printing larger motor parts are difficult because the parts become too brittle and may easily break. With this new development, Elkem introduces a powder that could truly transform motor parts manufacturing and given the fact that electrification has become a key priority for automakers, governments, and consumers alike, I am pretty sure the company will find partners who would like to assess the potential of this solution. In any case, that’s what I hope.

Remember, you can post job opportunities in the AM Industry on 3D ADEPT Media free of charge or look for a job via our job board. Make sure to follow us on our social networks and subscribe to our weekly newsletter : Facebook, Twitter, LinkedIn & Instagram ! If you want to be featured in the next issue of our digital magazine or if you hear a story that needs to be heard, make sure to send it to contact@3dadept.com