Fabric8Labs, a California-based company, is developing a technology called Electrochemical Additive Manufacturing short for ECAM. With a total of $73.3M raised to date – a $50M Series B investment round being the latest amount the company secured -, Fabric8Labs is backed by 12 investors who share their vision of shifting manufacturing with a sustainable approach.

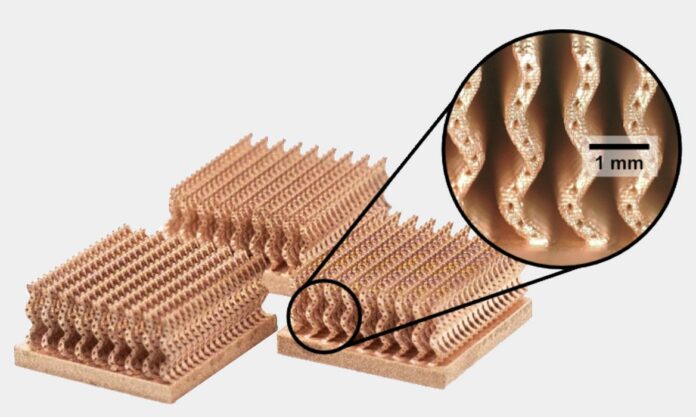

Their proprietary technology ECAM could produce pure copper components, which can be directly printed onto temperature sensitive substrates such as PCBs, silicon, or existing metal components. Without using powder, neither wire, nor lasers, the process can fabricate fully solid metal 3D printed parts. Its secret ingredient? Electroplating – a process that is often leveraged to provide a metallic coat to polymer 3D prints. Put simply, electroplating requires the part to be submerged in a metal solution before receiving an electrical current. The metal atoms then pile up on one of the electrodes, and form a solid surface.

According to Fabic8Labs, this capability comes at a time when electronics companies are seeking enabling technologies to address challenges with thermal management, power density, device form factor, and sustainability.

Through this process, ECAM enables the manufacturing of optimized designs to meet and exceed the increasingly stringent performance requirements in end-applications such as, high-performance computing (HPC), data centers, electric vehicles, wearables, RF communications, and a wide range of consumer electronics products.

In addition to enabling advancements in electronics – Fabric8Labs is developing medical device applications and micro-mechanical components. These applications leverage ECAM’s inherent advantages to produce extremely fine, complex features and high-performance alloys. As the company scales, ECAM will enable applications that require ultra-high resolution, such as advanced surgical tools, sensors, diagnostic equipment, and MEMs.

Beyond providing manufacturing capabilities that advance customers’ technology roadmaps, ECAM is environmentally sustainable and supports green initiatives. ECAM enables more than a 90% reduction in greenhouse gas emissions relative to alternative additive technologies and traditional manufacturing. The winning combination of capability, cost performance, and sustainability has accelerated customer adoption of ECAM across a wide range of market opportunities, the company states.

Remember, you can post jobopportunities in the AM Industry on 3D ADEPT Media free of charge or look for a job via our job board. Make sure to follow us on our social networks and subscribe to our weekly newsletter : Facebook, Twitter, LinkedIn & Instagram ! If you want to be featured in the next issue of our digital magazine or if you hear a story that needs to be heard, make sure to send it to contact@3dadept.com