A new partnership between space company Interstellar Lab and 3D printing company Soliquid will explore the use of additive manufacturing to scale up the production of modules for sustainable living on Earth and in Space.

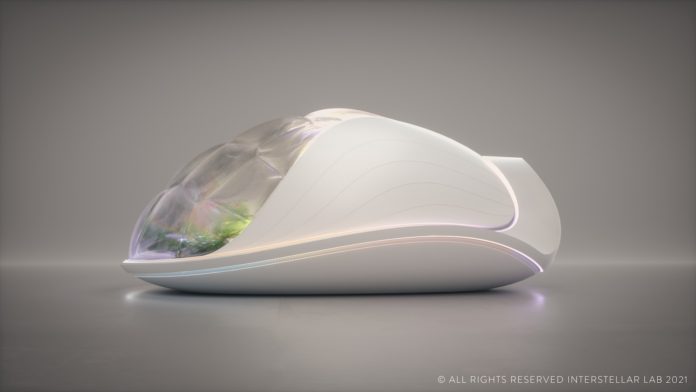

Interstellar Lab is a French-American company that manufactures controlled-environment habitat and crop cultivation modules. Named BioPods, these modules aim to ensure sustainable farming on Earth and life-support in space. The start-up spent several months of incubation at NASA Ames Space Portal. It relies today on a team of 15 former SpaceX, Airbus & Nest employees.

Soliquid on the other hand is a start-up of three years old that specializes in large-scale suspension 3D printing. The company has been developing a patented system to 3D-print concrete, resins and other materials in a controlled environment with a sustainable process.

As part of their partnership, Interstellar Lab will take its first steps into additive manufacturing, the ultimate goal being to meet the increasing demand of BioPods on Earth. It will include the development of innovative inflatable 3D-printed membrane and test 3D-printed regolith structures for lunar ISRU applications of the BioPod in partnership with space agencies.

That’s why, as a result of the partnership, Jim Rhoné, architect and founder of Soliquid, becomes Chief Product Officer at Interstellar Lab and will be in charge of BioPod’s development—from design to delivery—while overseeing the manufacturing process.

“Joining Interstellar Lab as CPO is a wonderful responsibility. As an architect, maker, and entrepreneur, it’s a dream to be part of this exceptional journey and team, sharing the same conviction that technologies we currently develop to aim at the stars will help preserve our ‘pale blue dot.’ Space and ocean explorations are intimately linked and, as we start revealing both of their mysteries, Soliquid will bring the best of its expertise to help turn Barbara’s vision into a reality. Fascinating times and challenges ahead,” said Jim Rhoné, founder of Soliquid.

A look at large-scale suspension 3D printing

By employing a reusable matrix and topology optimization workflows, Soliquid’s six-axis robot and extruder can 3D print complex parts in suspension, without support, faster and with less material than traditional prefabrication processes. In addition, Soliquid’s technology can help restore fragile ecosystems by 3D printing biomimetic constructive systems that foster the return of life and blooming of biodiversity.

Their latest artificial reef project Bathyreef for instance, supported by Mio, CNRS, Ifremer, Fondation Jacques Rougerie and carried out with Vicat, Tangram Architectes and Treex, is designed to be a sanctuary for marine life.

Brought together by their values, Soliquid’s 3D printing solution will provide an effective and cost-efficient way of manufacturing Interstellar Lab’s proprietary material systems developed for BioPods and EBioS. This partnership will offer new possibilities to envision the future of sustainable farming and habitats and open up new ways to think about performance and efficiency.

“I am very excited to have Jim joining us as CPO. His work is brilliant, and we have very aligned values not only in design but also when it comes to sustainability, preserving biodiversity and the future of humanity. Interstellar Lab is now accelerating, and we are very happy to team up with Soliquid to enter this phase,” said Barbara Belvisi.

Remember, you can post job opportunities in the AM Industry on 3D ADEPT Media free of charge or look for a job via our job board. Make sure to follow us on our social networks and subscribe to our weekly newsletter : Facebook, Twitter, LinkedIn & Instagram ! If you want to be featured in the next issue of our digital magazine or if you hear a story that needs to be heard, make sure to send it to contact@3dadept.com