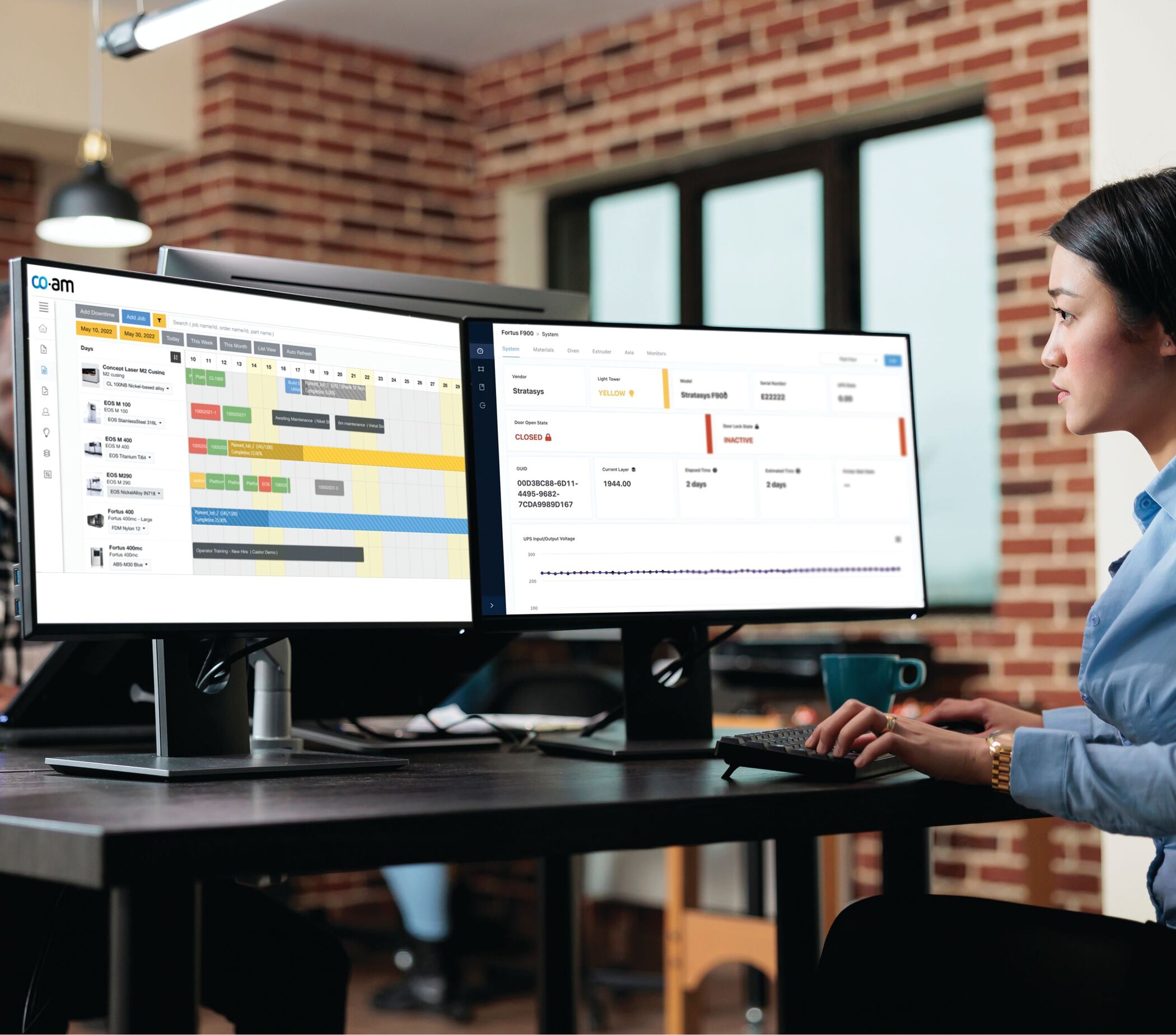

3D printing company Materialise has made a lot of announcements this year but the launch of their open software platform CO-AM is probably the most important one. Launched in May of this year, the platform provides companies direct access to multiple hardware technologies and their preferred tools from Materialise and other software developers, supporting them along every step of their AM journey – from planning and printing to quality control.

As charity begins at home, Materialise has first integrated its flagship data and build preparation software – Magics 26 – into the CO-AM platform. The integration comes alongside the software new workflow automation features, that aim to enable accurate monitoring of all manufacturing steps throughout the workflow, from data preparation through design iterations to the final printed part.

However, manufacturers will be more interested in exploring the range of new solutions that will be embedded onto the platform. Somehow, given Materialise’ long-standing experience as a software and a service bureau, the presence of third-party providers will somehow give more credit to their solutions’ capabilities.

In addition to AM-Flow, Castor and Identify3D, seven other companies joined the platform: Trinckle with its design automation tool for jigs and fixtures, Twikit with its design automation and automated order creation solution for mass customization solution, Additive Marking that enables digital traceability through automated labeling and authentication technology; SLM Solutions that will enable printer connectivity as well as monitoring and document machine data, and AMT, DyeMansion, and PostProcess that will bring tools to automate and track post-processing steps.

“With these new partnerships, the CO-AM community continues to grow, creating the first end-to-end software platform that offers an open ecosystem for the additive manufacturing (AM) industry,” said Bart van der Schueren, CTO of Materialise. “Collaboration is key to realize the potential of additive manufacturing and to give our customers seamless access to a full range of software tools to plan, manage and optimize every step of their 3D printing process.”

In a nutshell, the new solutions encompass automate design, labeling, machine monitoring, and post-processing. As Senior Director of CO-AM Vishal Singh, said during the press briefing at Formnext, every step of the manufacturing process at some point requires a software tool, and the biggest challenge they have had, ever since they started Link3D, now a Materialise company, was to enable software solutions to talk to 3D printers. “That’s something we are able to do now with the CO-AM platform and our partners”, Singh said. Not to mention, for these partners, this means benefitting from the opportunity to reach new customers more efficiently.

In a nutshell, the new solutions encompass automate design, labeling, machine monitoring, and post-processing. As Senior Director of CO-AM Vishal Singh, said during the press briefing at Formnext, every step of the manufacturing process at some point requires a software tool, and the biggest challenge they have had, ever since they started Link3D, now a Materialise company, was to enable software solutions to talk to 3D printers. “That’s something we are able to do now with the CO-AM platform and our partners”, Singh said. Not to mention, for these partners, this means benefitting from the opportunity to reach new customers more efficiently.

Remember, you can post job opportunities in the AM Industry on 3D ADEPT Media free of charge or look for a job via our job board. Make sure to follow us on our social networks and subscribe to our weekly newsletter : Facebook, Twitter, LinkedIn & Instagram ! If you want to be featured in the next issue of our digital magazine or if you hear a story that needs to be heard, make sure you send it to contact@3dadept.com