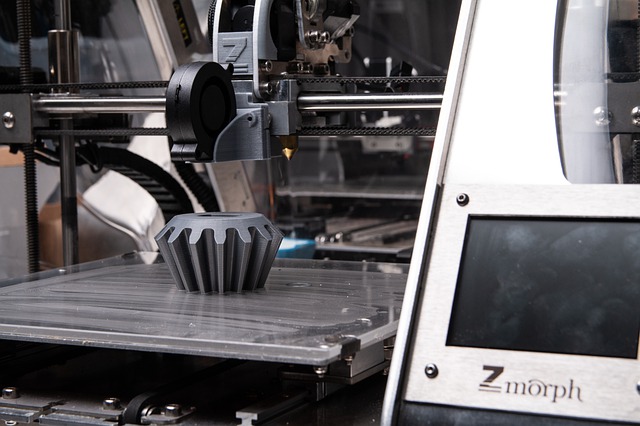

3D printing has been around for decades. The earliest 3D printers were already producing goods in the mid-80s. But it was only during the past decade that it has infiltrated various industries, changing the way companies do business.

3D Printing Boosts Production Speed

Before a product can get to market, it will have undergone at least two design cycles which can take months. It could literally take a year before you can sell your newest product to your customers.

3D printing can shorten the design cycle considerably. Prototypes can be made and tested within days. Products can be on the shelf in a matter of months. What does this mean for your business? Adopting this technology can give you a competitive advantage. But it also means that you can’t afford not to. Big businesses can easily afford this technology which will enable them to move faster. Your company will need to do the same if you want to remain profitable.

Product Testing and Sales

When you’re releasing a new product, it can be hard to predict how much you’ll actually be able to sell. With traditional manufacturing, it’s more cost-effective to go with mass production rather than small batches of goods at a time. 3D printing, on the other hand, allows you to test your product at a considerably low cost. It also enables you to test your market without wasting resources. You can choose to produce small batches to see how well your product will be received while keeping operational costs down.

Increased Opportunities

When it comes to 3D printing, the question isn’t “what can you print,” but “what can you NOT print.” This technology promotes innovation and opportunities. It allows companies to expand their product offerings, to enter markets that they found difficult to enter prior to adopting this technology. 3D printing also allows businesses to become more daring, to test more ideas, and to imagine out-of-the-box solutions.

Manufacturing as a Service

We’ve all heard about software as a service or SaaS. But Maas? Because of 3D printing, many manufacturers are changing their business model into one that is service-based.

These companies offer customers a platform where they can find a 3D printing service that can accommodate their order at a cost to their liking. One example is 3D Hubs. This platform connects companies that have 3D printers but weren’t utilizing their full potential with those that are still reluctant to adopt the technology into their processes. Because of platforms like these, small to medium-sized businesses can create additional revenue that will more than make up for the investment they made to purchase the software, equipment, and materials.

Supply Chain Consolidation

One huge benefit of adopting 3D printing is that it can simplify a company’s supply chain. Instead of having end-use parts manufactured elsewhere, it can opt to make them in-house instead. In addition, this technology can handle complex designs. With traditional manufacturing, such a design will require several components made separately before being assembled into a single unit. 3D printing, on the other hand, can build the entire unit layer by layer. This reduces the number of parts that will need to be procured, reducing the complexity of the supply chain and decreasing the risk of supply chain disruption.

What does this mean for your business?

- You will have more control over the quality of your components.

- You reduce production costs. 3D printing uses less material and even allows you to repurpose used material.

- You won’t have to worry about a supplier not being able to provide you with the parts you need. Instead, you can enjoy a more reliable and consistent production level.

Mass Customization

There is increasing customer demand for more customized or personalized experiences. Prior to 3D printing, providing products that have been built to meet the needs or whims of a specific customer can be quite expensive. The company will need to invest substantially in customized tooling to create customized parts. But with a 3D printer, all you need is a digital file that contains a customized design. One company that has embraced mass customization is Wiiv which offers sandals with custom-fit 3D-printed insoles.

To Sum Up

As you can see, 3D printing has had a transformative influence on the way companies do business. And as technological advancements continue, there’s no doubt that there’ll be more changes to come. Maybe there will be less manufacturing done abroad as more and more companies will be capable of in-house production. Possibly there will be a rise of “home factories” where consumers will be the ones printing their personalized products. Who knows? One thing’s for sure. It’s no longer business as usual.

About the author: Louisa is a content marketing professional and editor creating her successful career past 2 years atD3D Printing. She is a goal-oriented, creative individual with a unique voice in writing, editing, and optimizing content for various projects. She’s a devoted mom and an excellent piano player.