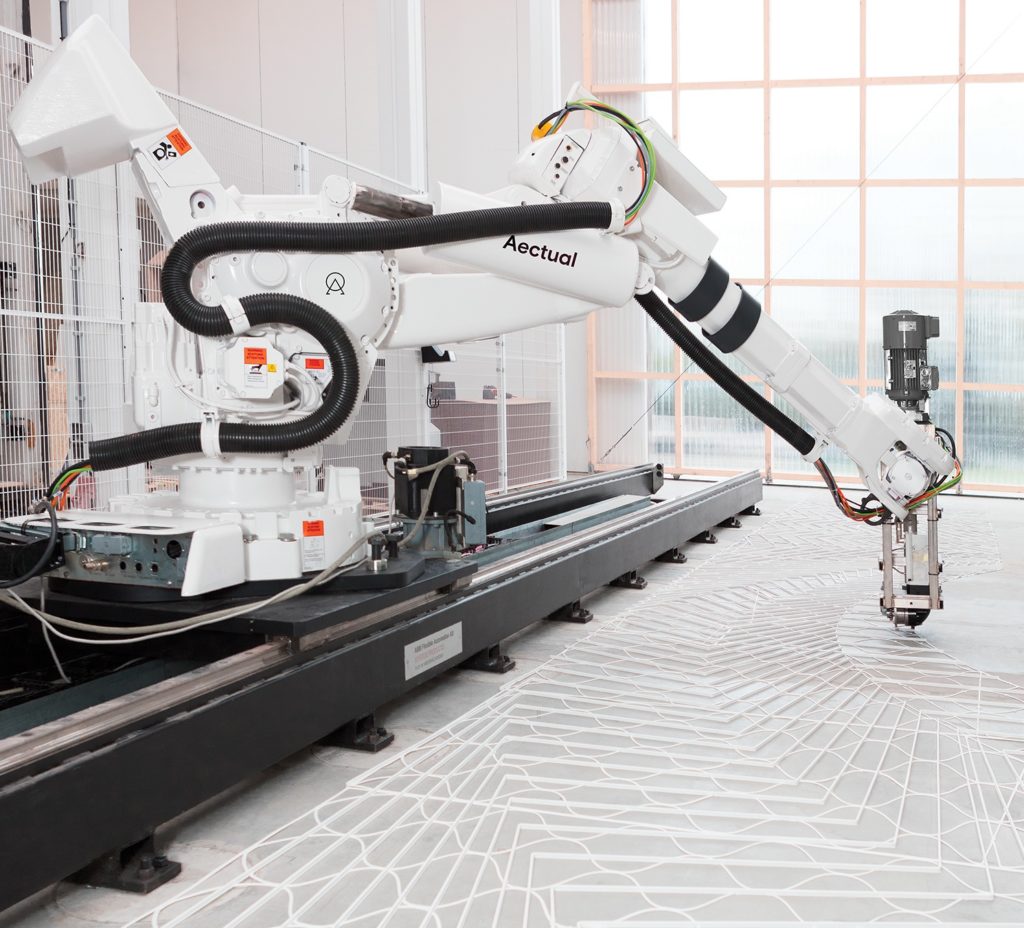

Although construction 3D printing remains one of the most fascinating fields when it comes to technology applications, it truly lacks from mass customization. There is a bunch of companies out there that has been working on this challenge, but one of them has been able to reach a milestone: Aectual.

One of the most fascinating applications of 3D printing is seen in the construction & architecture industries. It still looks undoable, yet there is a bunch of companies that are pushing the boundaries of the technology in that area.

Founded three years ago by three architects and 3D-print experts, the company has developed a platform with the same name. Over time, we have been covering some of the beautifully designed, modern 3D-printed architecture and interior items achieved by the company but all of them was always tailor-made.

Today, Aectual is going one step closer to its goal (which is to produce tailor-made buildings and interiors cleaner, faster, and better) by launching a design-to-delivery platform alongside the beta launch of its commercial web shop for consumers.

The beta process would reduce the cost of custom-made architectural products by 50%, which would be up to 10 times faster than the previous one. It would also eliminate waste, and reduce materials usages and CO2 emissions.

“Aectual addresses a serious global challenge: the construction sector accounts for 39% of all global carbon emissions and is one of the largest polluting industries in the world. Aectual’s turnkey platform enables AEC professionals and consumers to create beautiful, customized XL 3D-printed buildings, architectural and interior design products from 100% recyclable, renewable materials that minimize waste and don’t harm the planet,” said Hedwig Heinsman, co-founder and Chief Commercial Officer, Aectual. “We enable world-class architects, designers and brands to realize their own bespoke designs on demand, at any scale and in any building, and to create truly unique, 100% sustainable products without being slowed down by extensive prototyping and long lead times.”

The main advantages of this 3D printing additive manufacturing process are that it is entirely waste-free and a majority of the company’s products utilize circular plant-based plastics.

After use, Aectual takes back the building products and directly recycles and reprints them into new products. Depending on the product type, this results in a 35% to 95% material reduction due to its parametric designs, the number of materials needed, special manufacturing and product design optimization.

The Aectual 3D-printed XL architectural platform features 12 signature products in seven categories that users can customize to their unique taste, including:

- Flooring: terrazzo pattern — available in bio or ultra-thin bio

- Furniture: curtains and bookcases

- Façade Cladding and Wall Paneling

- Outdoor: sun screens and canopies

- Concrete Elements: stairs, pavements and façade cladding

- Interior Design: planters, room dividers and table screens

AECTUAL_circular_3Dprinted_furniture

From a technical perspective

The Aectual platform utilizes customizable engineered parametric products, an easy-to-use (customized) design dashboard and proprietary robotic XL 3D-print technology. AEC-industry professionals can upload and create their own product versions or simply go to the Aectual website, pick a terrazzo floor pattern, wall panel, room divider, or sun canopy, for example, and then customize it to their taste. Once ordered, Aectual 3D-prints and installs the product.

To facilitate global deployments, Aectual has built a stable international ecosystem, partnering with reliable multinationals such as Henkel (materials), ABB (robotics) and Arup (engineering). A key factor in Aectual’s success is the combination of the three pillars of the AEC industry (Architecture, Engineering and Construction) into a one-stop-shop solution: digitally linking architectural design parameters with engineering constraints, and then producing a verified 3D-print file that is constructed with Aectual’s proprietary 3D-printing technology. The combination enables fast, high-quality product production on an industrial scale and makes custom-made architectural design available to the masses.

AEC-industry professionals are invited to participate and sign up for the Aectual enterprise beta version at https://www.aectual.com/login. Prices start at $24 per square foot (€200 euros per square meter) and items are typically more affordable than their conventional, custom-made counterparts. Consumers can choose from a selection of circular furniture and decorative pieces, such as room dividers, table screens and planters, which can be directly purchased or customized to the buyer’s exact taste. Prices start at €500 euros.

Remember, you can post free of charge job opportunities in the AM Industry on 3D ADEPT Media or look for a job via our job board. Make sure to follow us on our social networks and subscribe to our weekly newsletter : Facebook, Twitter, LinkedIn & Instagram ! If you want to be featured in the next issue of our digital magazine or if you hear a story that needs to be heard, make sure to send it to contact@3dadept.com