For about a year now, 3 partners have been discretely labouring on a strategic basic research project that lays the groundwork for next-level electrical machines. The project is not finished yet; rather than rushing to the exit, the research organisations want to gain in-depth understanding of the involved materials and technologies. Here is a status update and an outlook.

Additive Manufacturing for Electrical Machines (AM4EM) is an ambitious research project by Ghent University, KU Leuven, and VITO, on the various ways 3D-printing can improve the performance of Electrical Machines. No, this project is not about printing your next coffee machine. Rather, the aim is to achieve more energy-efficient – and thus more ecological – electrical motors (stator/rotor cores).

Imagine the perfect motor – that’s one where you have combined the best insulating and conductive materials in the best possible design – where the impact of the current is optimally converted into actual movement. The main challenge to realise this perfect motor is to combine these conductive and insulating materials into complex multi-material geometries. This is a big challenge because multi-material 3D-printing is basically still in its infancy. Hence, all materials involved, all printing technologies and all designs have to be evaluated thoroughly.

VITO, an independent research organisation in the area of cleantech and sustainable development, headquartered in Flanders, has been working on 3D-printing since 2006. More specifically, they have been researching 3D-printing viscous powder loaded pastes, an underexposed segment in Additive Manufacturing. This paste printing – with ceramics and metals, amongst other – is one of the technologies used in the project.

Quite some important steps forward have been realised already. Micro-extrusion 3D-printing of copper paste has led to printed parts without printing defects, a relative density of 95 – 99% and an impressive electrical conductivity of 90 – 102% IACS. If that sounds too exotic for you: it means it is indeed possible to print pure copper with the properties needed for the applications at hand.

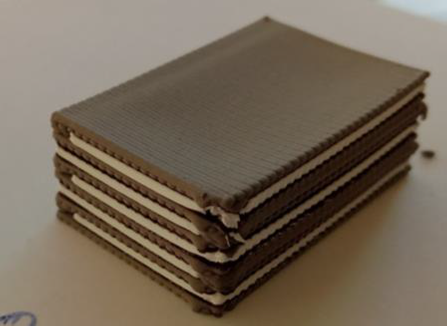

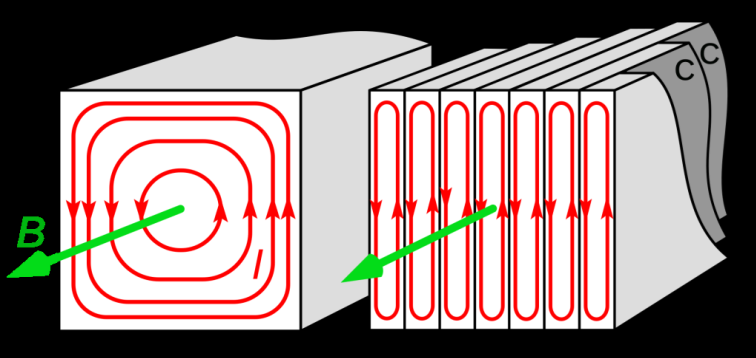

Positive results have also been achieved with the 3D printing of Fe-Si steel, needed for the cores of the motors. The next step is to print multi-material combinations for the magnetic core stacks, whereby a layer of ceramic insulator alternates with Fe-Si steel layers.

Although the results look satisfying at first sight, there are still challenges related to, for example, uniform shrinkage of the material and warping of the layers.

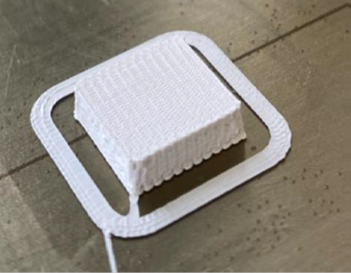

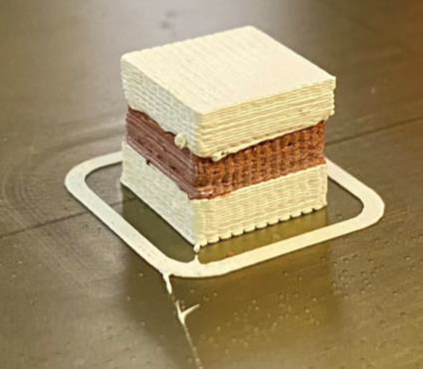

KU Leuven is well-known in the Additive Manufacturing industry; they have been at the cradle of 2 world-renown companies: Materialise and Layerwise (now 3D Systems). In this project, they are focusing on “Fused Filament Fabrication” (FFF) of metals and ceramics. Or rather: they print polymer filaments with a high content of metal or ceramic powder. The polymer in the filament is only needed to make the material “printable” and is removed after printing. Here, too, the challenge is only partially related to the 3D-printing itself; debinding and sintering require careful analysis as well to determine the optimal parameters such as temperatures, solvents, extrusion width or speeds, et cetera.

KU Leuven’s efforts, too, have resulted in relative density results above 95% for copper and 97.3% for ceramic, and even for combinations of both materials in one print.

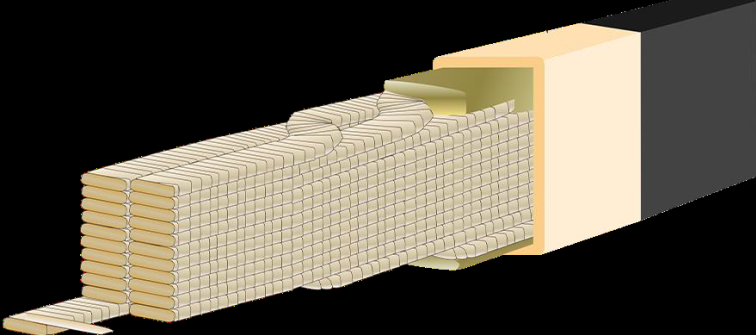

Ghent University has thorough expertise in multi-physics models for Electrical Machines. After all, this quest is not only about 3D-printing and materials. The complexity of how currents actually flow through conducting materials, requires in-depth simulation expertise. Or, stated differently: the design of crucial motor parts has a thorough impact on how the electrical currents interact with the magnetic field to create torque. By consequence, the design details strongly determine how efficient your machine will ultimately be. You will have to admit they have come a long way from the typical wound cores, when looking at the following designs:

Even if you just had some basic STEM-education, however, you may understand that these smart designs can make quite a difference when it comes to the efficiency of the resulting magnetic flux.

These combined efforts – on different printing techniques, design and material improvements, will deliver innovative MM-AM processes that can be applied for sensors, radars, actuators, electrical machines, etc. Ultimately, AM4EM targets an increase in energy efficiency by 5%-point (compared to small induction machines) and an increase in power density by 40%.

So far, it looks the project is on track to achieve exactly that. This is not some R&D-pleasantry: the fundamental research and development steps taken in the AM4EM project are in the end essential in order to decrease the energy consumption of our society as a whole.

Remember, you can post job opportunities in the AM Industry on 3D ADEPT Media free of charge or look for a job via our job board. Make sure to follow us on our social networks and subscribe to our weekly newsletter : Facebook, Twitter, LinkedIn & Instagram ! If you want to be featured in the next issue of our digital magazine or if you hear a story that needs to be heard, make sure to send it to contact@3dadept.com