Failed prints and bad results constitute one of the major issues, operators encounter during a printing process. These hurdles are often the result of wrong printing settings faced by 3D Printer users.

To address this challenge, Fabcontrol introduces a new software tool, 3DOptimizer. FabControl SIA is a standalone spin-off from 3D printer manufacturer Mass Portal, backed by investments from Rolands Moisejs Group, Overkill Ventures, EKJ Investments LLC and a private Swiss investor.

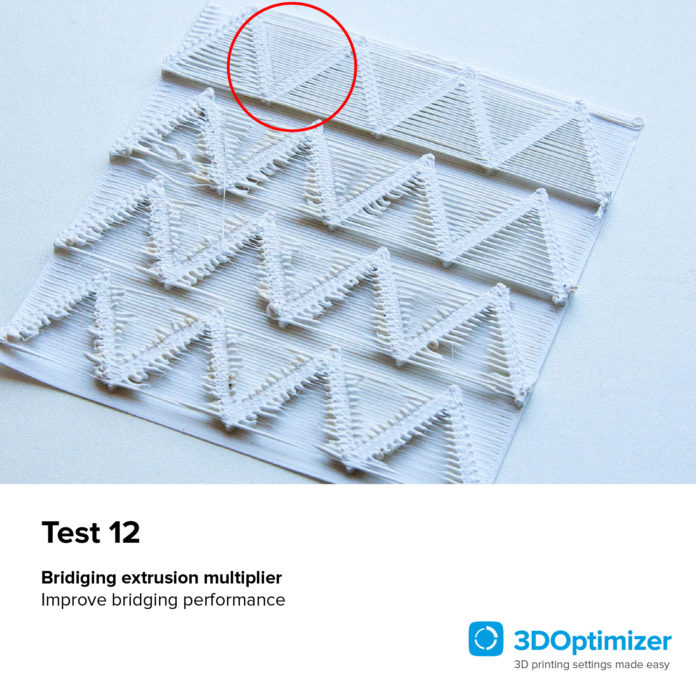

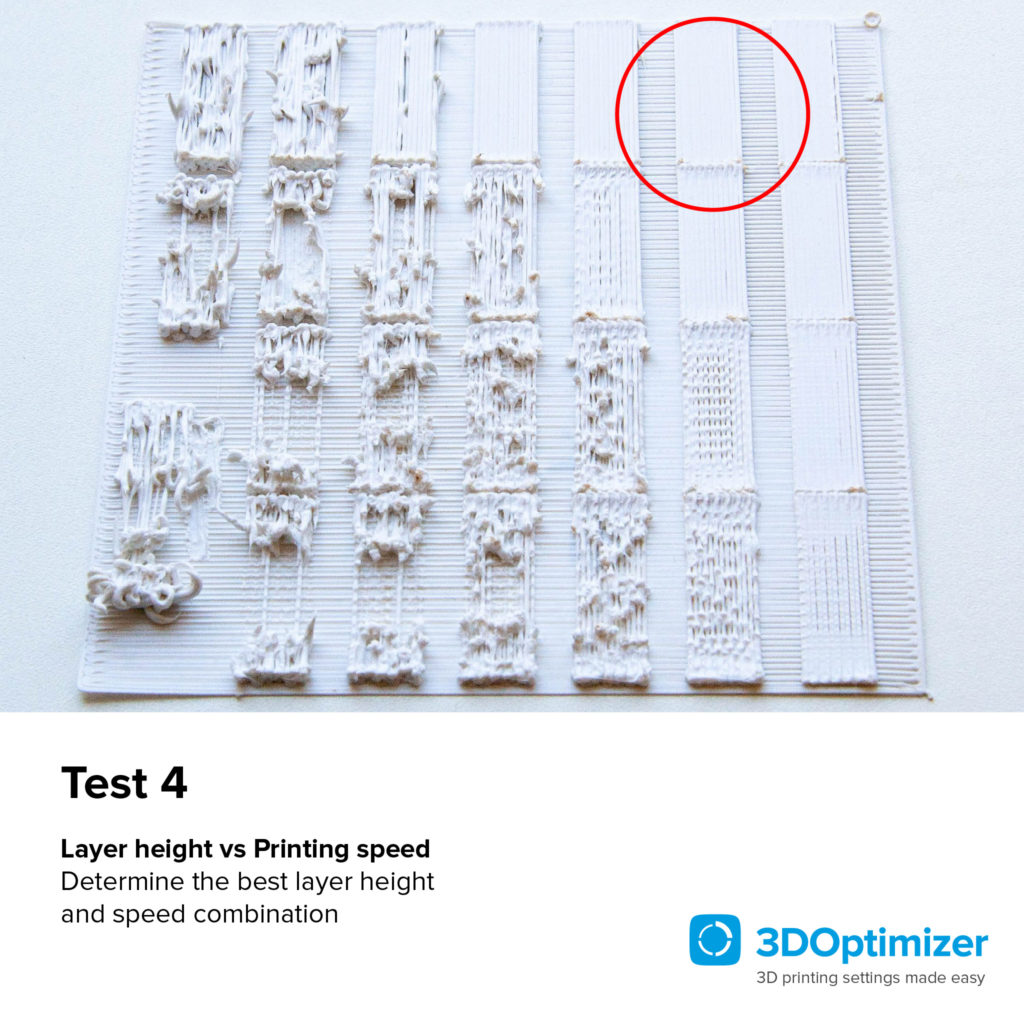

With the goal of improving the output from existing printers and facilitating the adoption of new materials, 3DOptimizer removes long hours of trial and error. It requires a few meters of filament to enable the 3D printer user to evaluate multiple parameter combinations at once.

This means that by printing the tests and selecting results that work best, process parameters are tailored for the particular machine and material. Since this is not simulation, but real-world printing tests, working settings can be developed also for machines and materials that are custom, non-standard or off-spec. The output of 3DOptimizer is configuration parameters for slicing software — users can download configuration files for the most popular slicers.

Even though it is only compatible with FFF/FDM 3D printers, Fabcontrol’s software tool capabilities are similar to Castor’s 3D screener, a software tool that helps to choose the “right additive manufacturing process depending on geometry, material and financial analysis”.

Speaking of the 3DOptimizer, Janis Grinhofs, co-founder of FabControl and former CEO of Mass Portal states: “this project is based on research by Dr. Georgijs Bakradze. It started internally in a 3D printer company — we needed a systematic way to make new materials work. We know what it takes to achieve best results from FFF technology. You need to bring materials science, hands-on 3D printing, hardware and software experience together, and spend quite a bit of time. We quickly saw our software could help most users of 3D printers spend less time on trying to “dial in” their setup. It’s good to hear that it does.”

Compatible with FFF/FDM 3D printers that support gcode, as well as self-built machines, the new software tool is available as an online service at 3DOptimizer.com.

Remember, you can post free of charge job opportunities in the AM Industry on 3D ADEPT Media or look for a job via our job board. Make sure to follow us on our social networks and subscribe to our weekly newsletter : Facebook, Twitter, LinkedIn & Instagram ! If you want to be featured in the next issue of our digital magazine or if you hear a story that needs to be heard, make sure to send it to contact@3dadept.com