Realize, Inc., 3D printing service bureau, bought EnvisionTEC’ Vector 3SP printer to beta test new engineering materials under development with Somos.

The Indiana-based 3D printing service bureau is recognized for its rapid prototyping. With its dozen 3D printers, the company provides services to customers from different sectors: automotive, medical, electronics and consumer goods markets.

For Realize President Todd Reese, adopting Vector 3SP printer was an easy decision to take. “Somos has been our vendor since day one. We have built a great partnership with their team, so we jumped at the chance to beta test their collaborative efforts with EnvisionTEC,” he said. “We’ve built many different parts on the Vector, from large, chunky parts to small, delicate, detailed parts. We have been able to pull off a couple of geometries that we struggled with on the SLA technology. There were cases of noticeably better detail, crispness and dimensional accuracy by comparison.”

What is 3SP technology?

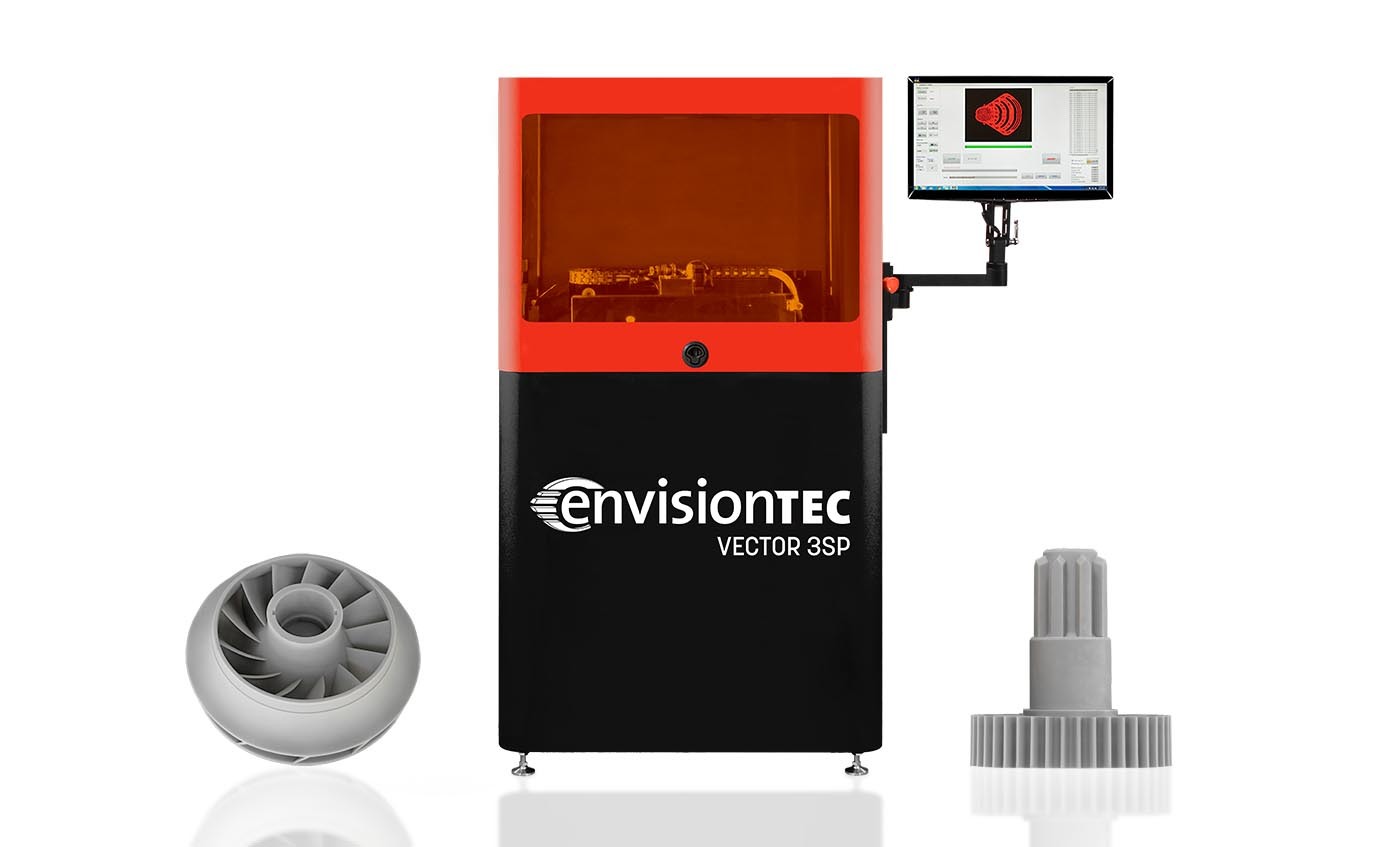

The Vector 3SP has a build area of 300 x 200 x 275 mm (11.8 x 7.9 x 10.8 in.) with XY resolution of 100 µm (0.004 in.). The machine can print a wide range of engineering-grade materials such as tooling materials for short-run injection molding.

The patented 3SP (Scan, Spin and Selectively Photocure) printer incorporates a unique process to cure photopolymers in a large vat up to 457 x 457 x 457 mm (18 x 18 x 18 in) in the Xede 3SP model.

“Manufacturing customers continue to learn what dental laboratories have known for years now — 3SP technology is fast, reliable and accurate for production 3D printing in a large build envelope,” said Peter Denmark, EnvisionTEC’s director of manufacturing sales in the America.

A white paper explains the importance of 3SP for manufacturing and production at EnvisionTEC.com/learn3SP.

For further information about 3D Printing, follow us on our social networks and subscribe to our newsletter!

//pagead2.googlesyndication.com/pagead/js/adsbygoogle.js

(adsbygoogle = window.adsbygoogle || []).push({});