Home =

directed energy deposition - search results

If you're not happy with the results, please do another search

AWI targets the additive manufacturing industry with a new “Exotic nickel alloy wire”

Alloy Wire International (AWI), a UK-based company known for developing wire, bars and wire rope in High Performance Exotic Alloys, now ambitions to serve the additive manufacturing industry with a nickel alloy wire range....

AddUp and ECM Group to develop thermal treatment solutions for metal 3D printed parts

Metal 3D printer manufacturer AddUp and heat treatment equipment manufacturer ECM Group join forces to develop thermal treatment solutions dedicated to metal 3D printed parts. As a manufacturer of L-PBF and Directed Energy Deposition...

Multi-Material 3D printing: where does the drawback lie?

Multi-material 3D printing is hot. Who wouldn’t want to receive a part that meets the 'best value for money' criterion? That’s the most important unique selling proposition (USP) of multi-material 3D printing. Like most...

A collaborative team explores Multi-Axis Metal Additive Manufacturing to manufacture overhang geometries without support structures.

Experts from Promation, ModuleWorks, and Multi-Scale Additive Manufacturing (MSAM) Laboratory of the University of Waterloo have explored a new method for manufacturing overhang geometries without the need of support structures.

Promation brings here its expertise...

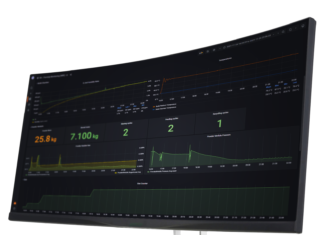

AddUp unveils new software solution for real time data monitoring inside the 3D printer

Machine manufacturer AddUp announces the launch of a multi-scale monitoring software that can provide real-time monitoring of what’s happening inside the 3D printer. Named AddUp DashboardsTM, the solution is compatible with all AddUp FormUp...

Unveiling the disguised complexities of Wire-Arc Additive Manufacturing

With a first patent granted in the 1920s, Wire-Arc Additive Manufacturing, short for WAAM, is certainly one of the oldest AM processes that exist, yet the technology is the least highlighted in the range...

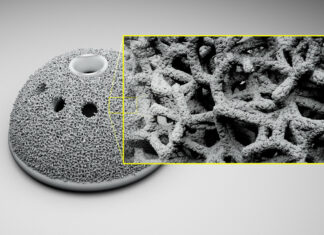

Kugler develops Antifriction Parts Produced through the Hybridation of AM, Conventional Casting and Machining.

Switzerland-based parts producer Kugler highlights today an issue that is not often highlighted in manufacturing: friction. The company has dedicated its core business to solve such problems through the manufacturing of antifriction parts.

Those parts...

New standard for Industrial AM Sites vs the revised DNV AM Standard

No matter how powerful your Additive Manufacturing solutions are, standards remain the ultimate performance measurement tools that confirm your production processes and environments are uniquely positioned to ensure the quality of the end products...

Can manufacturers bet on hybrid manufacturing processes?

As its name suggests, the purpose of “Hybrid Manufacturing” is relatively easy to understand: taking the advantages of both additive and subtractive technologies within the same machine. The concept is relatively new as first...

A custom-built 3D printer helps 3D print NASA’s 10-foot (3m) tall rocket nozzle liner demonstrator

Remember the Rapid Analysis and Manufacturing Propulsion Technology project aka RAMPT? NASA’s project that consists in advancing AM technologies for the production of rocket engine parts using metal powder and lasers.

In this vein, NASA is...