Home =

directed energy deposition - search results

If you're not happy with the results, please do another search

Sustainability with AM: The four key takeaways from AMGTA’s First Commissioned Research Paper

Two years ago, the Additive Manufacturer Green Trade Association (AMGTA) selected the Golisano Institute for Sustainability (GIS) at Rochester Institute of Technology to conduct a life-cycle assessment (LCA) research project. The independent piece of...

Dossier: Understanding the complexities and opportunities of Multi-Laser Additive Manufacturing

One thing fans of Star Wars and fans of laser games would likely agree with, is that lasers are super cool. Why? You could ask. Because of speed. More lasers mean more agility and...

For an undisclosed amount, Berlin.Industrial.Group acquires metal 3D printing company Gefertec

Gefertec, a manufacturer of wire-based Directed Energy Deposition (DED) Additive Manufacturing machines, has been sold to Berlin.Industrial.Group (BIG) Holding, a coalition of several companies operating in medical and energy technology, tool construction and mechanical...

DNV updates its additive manufacturing standard with new edition

The independent energy expert and assurance provider DNV has published a new edition of DNV-ST-B203 Additive manufacturing of metallic parts.

The standard, which is the result of a joint industry project, now includes baseline requirements...

DOSSIER | Heat Treatment for Additive Manufactured Parts: A Dirty Little Secret that is yet to be understood

In a previous dossier dedicated to the use of furnaces in additive manufacturing, we found out that the reasons that may help catalogue the type of furnaces manufacturers will use, are often dependent on...

Lockheed Martin and Sintavia to explore metal additive manufacturing opportunities as an alternative to castings and forgings

This is an interesting partnership: a global security and aerospace company (Lockheed Martin) on the one hand and a designer and manufacturer of advanced propulsion and thermodynamic systems (Sintavia) join forces to expand research...

ANDRITZ Savonlinna Works Oy & FAME 3D print large pressure vessel

Pressure vessels are enclosed containers that hold liquids, vapors, and gases at a pressure significantly higher or lower than the ambient pressure. Their size varies from whether they are use within a residential environment...

Guaranteed on providing extra-large scale metal wire and arc (WAAM) additive manufacturing services

Ageing installations are a common issue in many industries. Assets are increasingly used beyond their original design life, which results in parts becoming high-risk for downtime or failure. This can result in significant non-productive...

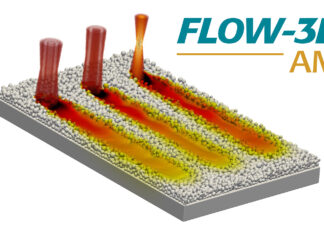

Why do we use CFD Simulation in Additive Manufacturing? Flow Science told us and will showcase it at Formnext 2022

Our means of transport (car, train, plane, etc.) or household appliances are a few examples of everyday products that may require the use of computational fluid dynamics (CFD) in the product development process.

CFD is...

Optomec and Acme Manufacturing develop Automated Work Cell for the Additive Repair of Turbine Parts

Metal 3D printing company Optomec Inc. and Acme Manufacturing, an expert in robotic material removal systems have developed together a fully automated work cell initially optimized for repairing aviation compressor blades made of titanium.

The...