Home =

Cold Spray Additive Manufacturing - search results

If you're not happy with the results, please do another search

Meet VRC, a newcomer introducing Dragonfly Cold Spray Additive Manufacturing for in-field repairs

A new company popped up on our radar this morning: VRC Metal Systems (aka VRC). Headquartered in South Dakota, USA, the company introduces a Cold Additive Manufacturing solution designed for in-field repairs. Named Dragonfly...

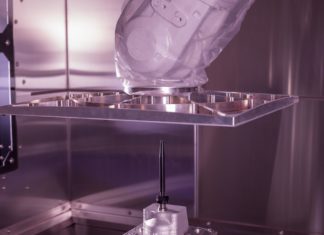

Phase3D to develop a quality inspection system for cold spray Additive Manufacturing

Phase3D, previously known as Additive Monitoring Systems, has been awarded a 2-year $1.25 million contract from the Air Force Research Lab to develop a quality inspection system for cold spray AM (CSAM).

The company that...

SPEE3D to develop SUBSAFE manufacturing materials with Cold Spray Additive Manufacturing

The US Navy has chosen metal AM company SPEE3D to develop materials as a part of a Naval Sea Systems Command (NAVSEA) project related to Expeditionary Maintenance and Sustainment that achieve Submarine Safety Program...

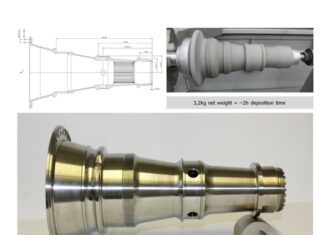

Impact Innovations GmbH develops a Cold Spray Additive Manufacturing (CSAM) process for Ti-6Al-4V

Remember this exclusive feature on Cold Spray Additive Manufacturing (CSAM)? One of the reasons why the process is an interesting production candidate is that since there is no heat, operators can easily explore the...

How to manufacture magnets using cold spray additive manufacturing?

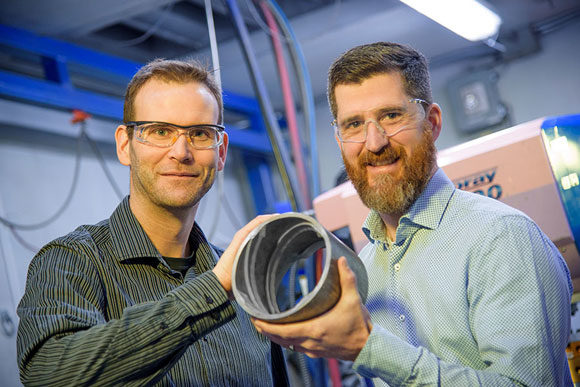

The National Research Council of Canada (NRC) developed a new process of fabricating magnets for electric motors without assembly. The fabrication process involves the use of cold spray additive manufacturing technique. The research has...

Updated: Large format Additive Manufacturing: Materials, Software and Costs

The article has been updated to reflect the fact that "most industrials often have in mind the use of machines with build volumes around 1 m3".

Most adopters of Additive Manufacturing (AM) share the same...

Understanding the infiltration and coating processes for Additive Manufactured parts

Whether it is light or cheap, a 3D printed part delivers value when it performs well. The thing is, achieving that performance often begins and ends at the surface. Ensuring the right surface of...

Linde and Impact Innovations develop new gas supply solution for post Additive Manufacturing process

Put a gases and engineering company together and a cold spraying technology expert together, and you’re likely to obtain a post additive manufacturing cold spraying gas supply solution. That’s what happened when Linde and...

Can manufacturers bet on hybrid manufacturing processes?

As its name suggests, the purpose of “Hybrid Manufacturing” is relatively easy to understand: taking the advantages of both additive and subtractive technologies within the same machine. The concept is relatively new as first...

What does “Supersonic” Additive Manufacturing look like?

In general, many seem to agree with the design flexibility and material efficiency AM provides but despite those undeniable benefits, one thing AM technologies manufacturers struggle to significantly improve in their process is speed....