The last time we spoke about DyeMansion, the post-processing company announced a partnership with Stratasys to mass-produce architecture 3D printed end-use parts. Over time, this alliance has been strengthened as the German company has added two new authorized sales partners to its distribution network – Advanced Tech and CATi (both headquartered in Illinois) – who will provide DyeMansion products alongside Stratasys technology. Furthermore, Stratasys Direct Manufacturing has ramped up its production portfolio with new DyeMansion equipment capabilities including the Powershot S and DM60.

Apart from this alliance, what raises the most interest in DyeMansion’s activities today, is the company’s recent improvement related to the VaporFuse Surfacing process for sealed surfaces. The post-processing technology is now compliant with FDA’s food contact regulations. This compliance is effective thanks to the development of the VaporFuse VF47 Eco Fluid, a solvent that can be used for contact with all food types for which the base polymer is both technically suited and authorized.

Speaking of the VaporFuse Surfacing process, it should be noted that a new eco-friendly solvent has been developed for vapor polishing Polypropylene (PP) parts. The new solvent is biobased and biodegradable. It is said to fulfill “high performance and sustainability standards at the same time”.

This solution is currently being validated with different Polypropylene materials and successfully tested for Ricoh PP, HP Ultrasint PP, ALM PP400, VoxeljetPP, AM Polymers PP03, Ultimaker PP (FDM printed), EOS PP1101 and DSM ARNILENE AM6002, the company states in a press release.

Improvements made in the Powerfuse S

The compliance with the food industry comes along with the addition of new features to the Powerfuse S.

As a reminder, the Powerfuse S integrates a fully automatic loading option, connectivity and batch tracking features. Suitable for a wide range of applications, the machine requires the use of an eco-friendly solvent approved by the EU for food packaging and cosmetic products and is equipped with a recycling process for the solvent to avoid waste.

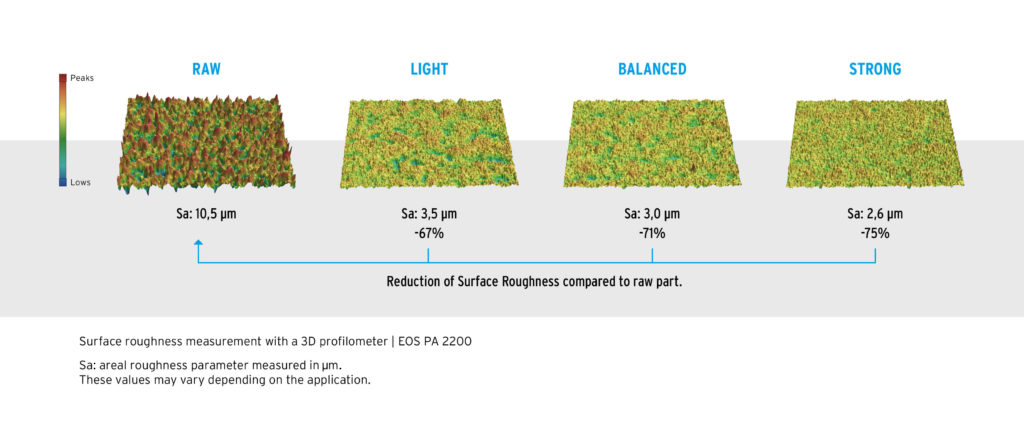

The new additions consist in different Levels of Smoothing – Light, Balanced and Strong -, each of them being adaptable for requirements of different applications. Those Levels of Smoothing are currently available for various materials such as EOS PA 2200, EOS TPU 1301, HP 3D HR PA 11/12 and HP BASF Ultrasint TPU 01.

Remember, you can post job opportunities in the AM Industry on 3D ADEPT Media free of charge or look for a job via our job board. Make sure to follow us on our social networks and subscribe to our weekly newsletter : Facebook, Twitter, LinkedIn & Instagram ! If you want to be featured in the next issue of our digital magazine or if you hear a story that needs to be heard, make sure you send it to contact@3dadept.com