As the first country that has been severely affected by the Coronavirus outbreak (aka COVID-19), China is officially known as the cradle of the pandemic. All industries in the country are joining forces to fight against it.

In this vein, based on the needs of the country, they quickly realized that the medical staff also quickly ran out of some essential equipment to treat patients.

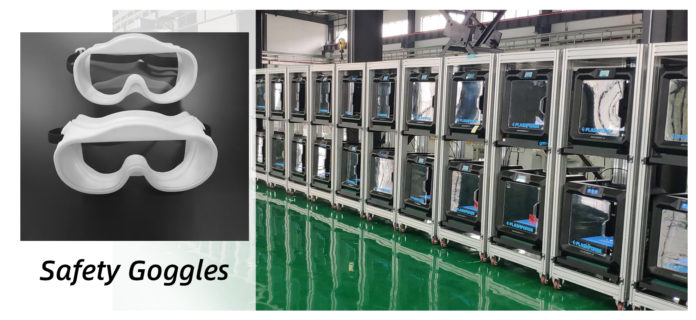

Medical protective clothing, face masks, and safety goggles are the most needed and scarce items for front line medical staff. Short supply is always a challenge, and the demand gap is even larger for the reason that safety goggles require long production cycles by traditional manufacturing.

To cope with this situation, a large safeguard instrument manufacturing enterprise in China used 200 Flashforge 3D printers Guider2 for the production of safety goggle production.

The daily output of 3D printing safety goggles has therefore been increased from 600 to 2,000, further realizing mass production, supporting the front line of anti-COVID-19 and alleviating the shortage of some medical supplies.

The technology perspective

The safeguard instrument manufacturing enterprise made various comparisons in the selection of equipment. Large printing volume, long-term printing stability and high accuracy are the most concerned features. After comparing many 3D printing brands, they finally chose Flashforge Guider2. At present, 200 Flashforge Guider2 have been put into production.

From a technology perspective, the R&D team of the manufacturer used 3D printing technology to design, develop and finalize the product within 153 hours, and finally realized the mass production of 3D printed safety goggles. It is reported that the 3D printing safety goggles are lighter and easier to wear, and they are better sealed and protected from fog for a long time.

At present, over 5000 pairs of 3D printed safety goggles have already been sent to the hospitals through donations. Now the company believed that the increased capacity will relieve the pressure of safety goggles shortage. In the future, the enterprise will further expand the capacity according to the needs. However, at that time, the daily output of goggles could reach 10,000 pairs.

Remember, you can post free of charge job opportunities in the AM Industry on 3D ADEPT Media or look for a job via our job board. Make sure to follow us on our social networks and subscribe to our weekly newsletter : Facebook, Twitter, LinkedIn & Instagram ! If you want to be featured in the next issue of our digital magazine or if you hear a story that needs to be heard, make sure to send it to contact@3dadept.com.