Software provider CoreTechnologie and Meteor Inkjet Ltd., a supplier of electronics, software, tools and services, are joining forces to enable better industrial 3D inkjet printing applications. Both companies will make their software environments converge and develop new tools for binder and material jetting solutions.

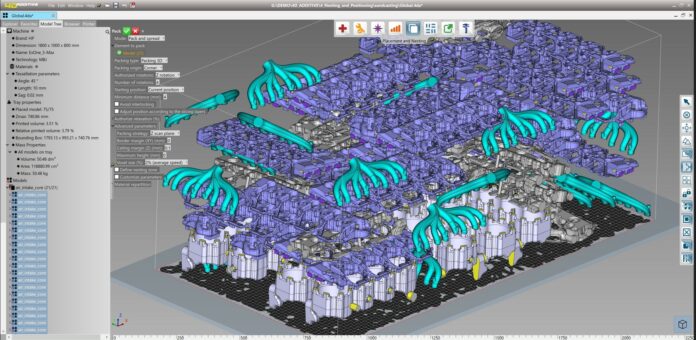

As a reminder, CoreTechnologie develops 4D_Additive, a software suite that offers functions for model repair, geometry analysis and optimisation, support, lattice and surface texture generation as well as nesting and slicing.

Combined with Meteor’s printhead drive electronics and Met3D Digital Front End, it provides printer manufacturers with a straightforward path from design to production of inkjet printing systems for additive manufacturing.

The implementation of inkjet technology for the application of binders or materials requires a close integration of the hardware and software of industrial printing systems and innovative tools for additive manufacturing, as well as the reading capabilities for all common CAD formats and the provision of the optimised 3D data in a special format for inkjet printers. This prerequisite is targeted by the new cooperation of the two specialists.

“Our collaboration with CT not only provides a clear development path for 3D printing system OEMs, but will also lead to important sustainability benefits for the industry, such as real-time optimisation of 3D sand casting prints with precise density control, reducing material waste and curing time“, Meteor managing director Clive Ayling said about this collaboration.

Remember, you can post free of charge job opportunities in the AM Industry on 3D ADEPT Media or look for a job via our job board. Make sure to follow us on our social networks and subscribe to our weekly newsletter : Facebook, Twitter, LinkedIn & Instagram ! If you want to be featured in the next issue of our digital magazine or if you hear a story that needs to be heard, make sure to send it to contact@3dadept.com