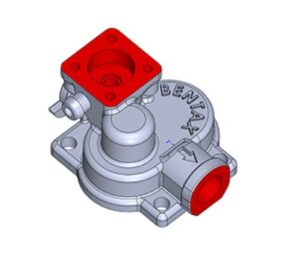

During their service of coffee machines, coffee supplier Bentax has experienced a challenge with the milk pump, where some parts wear out quickly. It is a big expense, as you cannot get spare parts for the pump, and therefore have to buy a brand new pump from the supplier. For this reason, Bentax is left with a large pile of useless milk pumps, which actually work fine apart from two worn out parts.

As part of the MADE Material Demonstration project, the Bentax team collaborated with the Danish Technological Institute; together they investigated whether the critical metal spare parts could be 3D printed so Bentax could reuse the expensive pumps instead of having to buy brand new ones – and at the same time see if the pumps could be made to last longer.

The project aims to provide a small or medium-sized company with a financing that goes up to DKK 100,000 (€ 13 442) so that it can solve a concrete challenge in the company or test a new technology in production.

“These milk pumps are the root of all evil in a coffee machine, because if they don’t work optimally, there are many other expensive parts around the pump that suffers. This requires many trips to the clients and means that the individual technician cannot handle as many customers, so it requires more employees, more service vehicles etc. So to stop the vicious spiral, it is important that the pump works optimally. We have chosen the most difficult task to test 3D printing, and the one that gives us the most challenges. If we can solve this, we can solve anything. In addition, we have ‘green mindset’ and would like to solve our tasks in a more responsible and sustainable way. So it would be interesting if we could digitize the inventory to a greater extent and at the same time have components manufactured locally instead of having them sent from the other side of the world”, says Anders Myrup, Technical Project manager at Bentax.

How did they proceed?

In the project, Bentax looked specifically at the 10 percent of the milk pump that typically wears out. It involves some gears and a small housing for these, and the problem is that the gears cut into the housing over time and make some tracks, which means that the pump cannot deliver the desired result.

“Initially, the aim is to pump some life into the broken pumps so that we can recycle them. In the long term, we would like to be able to make the spare parts rather than buying new pumps from the supplier, and we would also like to achieve a longer durability and a lower price compared to a new pump”, Myrup explains.

In the project, the entire pump has been scanned and measured at the Danish Technological Institute, who has made an identical digital copy. The housing has then been 3D printed in stainless steel and post-processed down to the desired tolerances, which are very fine. 3D printing was also tested for the gears, but they were not strong enough, and instead they have been milled out with a traditional CNC milling machine in a PEEK material.

After many discussions between the two teams, three different versions could be tested. At the end of the project, Bentax is not far from the goal in terms of achieving the desired result from the pump. The 3D-printed housing is completely in place, but some very fine adjustments still need to be made to the gears.

In the long term, the components must be surface treated with chromium nitride so that the surface does not break when the gears work against it, and the expectation is that this will increase durability.

The project is over and the Bentax team knows now metal 3D printing could be a solution for their spare parts. Plus, they are quite satisfied with where it is in terms of price. However, they still have a number of questions to answer.

“We see many more possibilities now, also beyond the parts we put into the machines. It could be specially designed tools or adapted holders and hooks for the work tables in the workshop, so that we can optimize our processes – and this is derived from this project. I think that when we have to develop our inventory and digitize it further, it will also be 3D printing that will form the basis”, Myrup concludes.

Remember, you can post job opportunities in the AM Industry on 3D ADEPT Media free of charge or look for a job via our job board. Make sure to follow us on our social networks and subscribe to our weekly newsletter : Facebook, Twitter, LinkedIn & Instagram ! If you want to be featured in the next issue of our digital magazine or if you hear a story that needs to be heard, make sure to send it to contact@3dadept.com