Caracol, a developer of industrial large-format 3D printing systems, is working with Airtech Advanced Materials Group and CMS, part of Scm Group to enhance specific areas of the large-format 3D printing process. Both companies provide a wide range of services to the AM industry.

The collaboration with Airtech

Airtech is a privately-owned manufacturer of vacuum bagging and composite tooling materials for prepreg/autoclave, resin infusion, and wet lay-up processes up to 799°F (426°C). The collaboration between Airtech and CMS has led to the qualification of the former’s Dahltram® Resins for integration with HERON AM large-format Additive Manufacturing platforms.

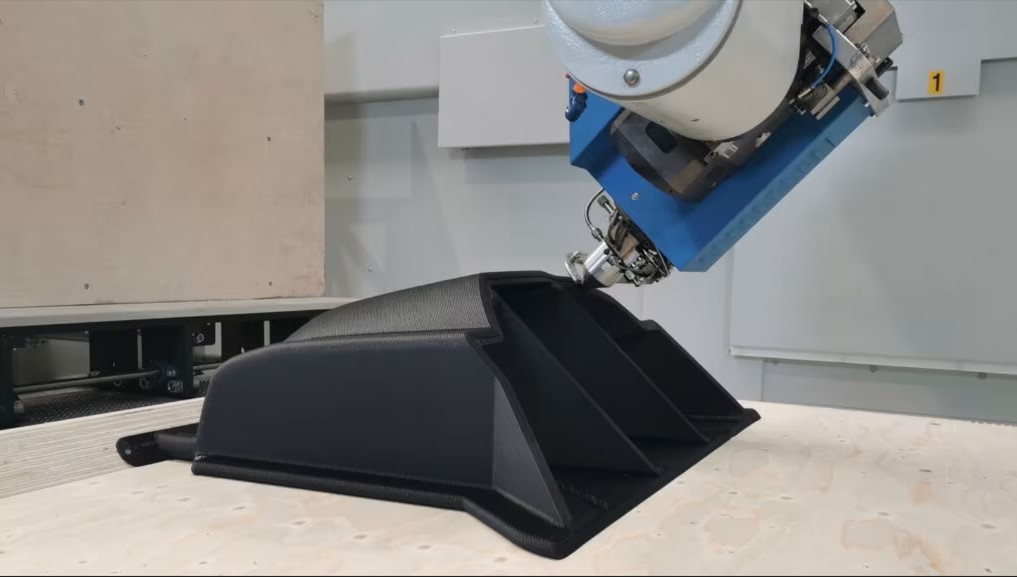

As a reminder, Caracol launches Heron AM in 2022. The modular, polymer, and composite pellet extrusion robotic 3D printer is continuously being optimized to ensure flexibility, process control and performance.

Airtech’s Dahltram® resin range would be suitable for multiple print platforms and offers unparalleled production flexibility with end-use material approvals. Rigorous thermal cycle testing, pressure leak testing, laser surface scanning and contact material testing have generated data that supports more than 500 autoclave cycles without degrading the Dahltram® tooling resins, a press release reads.

Furthermore, the launch of Dahltram® T-100GF marked Airtech’s entry into recycled-grade thermoplastic polymer resins for pellet-fed, large-scale 3D printing. These innovative resins are leading the way in recycled materials and have made a significant impact, particularly in sustainability initiatives.

Through this collaboration, Caracol will be able to offer Airtech’s resins to its customers worldwide.

The collaboration with CMS

CMS on the other hand, develops solutions for the processing of composite materials. The company produces machines and systems to process different materials, such as CNC multi-axis machining centers, thermoforming machines, and waterjet cutting

systems. Since 2018, the company began its journey in the additive manufacturing sector with CMS Kreator, an exclusive Large Format Additive Manufacturing Solution.

Caracol and CMS are now joining forces to develop different movement supports that will facilitate the production of large-scale AM components: on the one hand robotics with 6+ axes, and on the other 5-axis centers.

Thanks to this commercial collaboration between the two companies, it will be possible to accelerate technological developments and, most of all, support end-user’s adoption of LFAM technologies, by continuing to find new applications where large format 3D printing can deliver benefits in terms of lead time, costs, and sustainability, Caracol says in a press communication.

Remember, you can post job opportunities in the AM Industry on 3D ADEPT Media free of charge or look for a job via our job board. Make sure to follow us on our social networks and subscribe to our weekly newsletter : Facebook, Twitter, LinkedIn & Instagram ! If you want to be featured in the next issue of our digital magazine or if you hear a story that needs to be heard, make sure you send it to contact@3dadept.com