Boom Supersonic, the aerospace company building what it describes as the world’s fastest airliner, has announced the development of Symphony™, a new propulsion system designed and optimised for its Overture supersonic airliner.

The company will be working with three main partners for the development of this propulsion system: Florida Turbine Technologies (FTT) for engine design, GE Additive for additive technology design consulting, and StandardAero for maintenance.

Additive Manufacturing will be utilized to achieve low weight, low part count, and reduce assembly costs. Symphony™ will be a bespoke design leveraging proven technologies and materials to achieve optimal supersonic performance and efficiency.

Overture’s new propulsion system will operate at net zero carbon and meet Chapter 14 noise levels. When compared to derivative approaches, Symphony is expected to deliver a 25% increase in time on wing and significantly lower engine maintenance costs, reducing overall airplane operating costs for airline customers by 10%, Boom explains.

Boom made a real splash in our industry when it demonstrated that 21 3D Printed Titanium Parts could safely fly in its Supersonic XB-1 Aircraft. At the time, the company relied on Velo3D technology to achieve that performance. With GE Additive on board, and given the company’s track record of designing additively manufactured engine components—enabling more streamlined development, reduced weight, and improved fuel efficiency, there is no doubt this project would teach us new lessons but my hope is that the team leverages the highly anticipated GE Additive’s Binder Jet 3D printing Solution –whose details have been unveiled two months ago. After all, we can’t wait to see how the machine can live up to its promise to deliver quality parts, at cost, at scale and safely.

“We are excited to support Overture and Symphony,” said Chris Schuppe, General Manager Engineering and Technology at GE Additive. “GE Additive will bring industry-leading capabilities to Symphony, providing additive manufacturing design consulting and technology, while looking for additional areas to potentially collaborate.”

Symphony technical overview

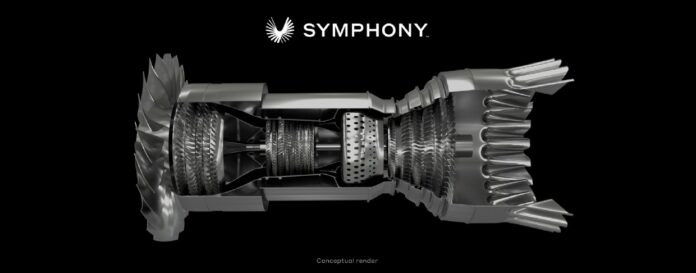

The Symphony propulsion system will be a medium-bypass turbofan engine with the same basic engine architecture that currently powers all modern commercial aircraft. Unlike subsonic turbofans, this new propulsion system will include a Boom-designed axisymmetric supersonic intake, a variable-geometry low-noise exhaust nozzle, and a passively cooled high-pressure turbine.

Engine design features reportedly include:

- Architecture: twin-spool, medium-bypass turbofan engine, no afterburner

- Thrust: 35,000 lbs at takeoff

- Fuel: optimised for 100% sustainable aviation fuel

- Single-stage fan designed for quiet operation

- Passively cooled high-pressure turbine

- Certification: compliant with FAA and EASA Part 33 requirements

With Symphony design already underway, Overture is on track to achieve type certification in 2029. Production is set to commence in 2024 at Overture’s Superfactory in Greensboro, NC, with rollout in 2026 and first flight in 2027.

Remember, you can post free of charge job opportunities in the AM Industry on 3D ADEPT Media or look for a job via our job board. Make sure to follow us on our social networks and subscribe to our weekly newsletter : Facebook, Twitter, LinkedIn & Instagram ! If you want to be featured in the next issue of our digital magazine or if you hear a story that needs to be heard, make sure to send it to contact@3dadept.com