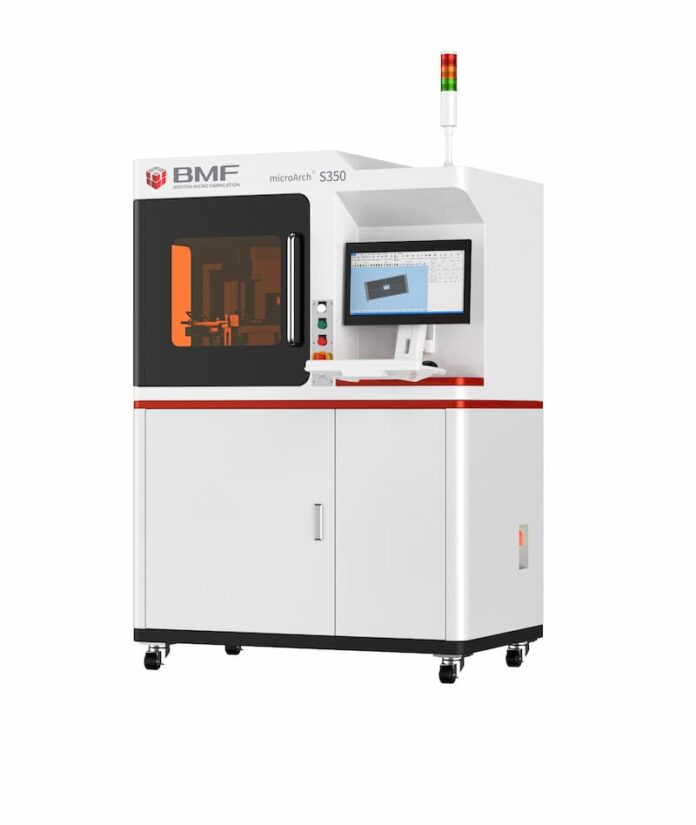

The latest member of Boston Micro Fabrication (BMF)’s portfolio of micro-precision 3D printers is the microArch™ S350; a version of BMF’s 25µm resolution system that is said to deliver the highest throughput in the company’s portfolio.

Built upon the company’s patented Projection Micro Stereolithography (PµSL) technology, a technique that allows for rapid photopolymerization of layers of liquid polymer using a flash of UV light at micro-scale resolution, the industrial 3D printer has a build volume of 100 x 100 x 50mm and fewer projection zones to improve print speed.

A new automated lateral membrane shift enables easier part removal or integration with a robotic arm, resulting in increased automation and ease of use for end-part production. Additional capabilities include automated resin fill and adjustment, a laser displacement sensor, and an advanced roller that spreads layers at greater speed.

Ideal for the production environment or labs, the microArch S350 can print both micro-scale parts with high-resolution features or small parts requiring high accuracy or precision. The new machine can process engineering and ceramic resins suitable for end-use parts, including two new materials that accompany this release:

- BMF MED powered by 3D Systems – A rigid amber material for applications requiring biocompatibility, translucency and/or thermal resistance. It provides parts with crisp details, that can be sterilized and tested at high temperatures, over 100 °C.

- LOCTITE 3955 – High-performance halogen-free flame retardant UL94-V0 high modulus photopolymer resin. Printable at 60°C.

“BMF has become the industry leader for printing small and micro-sized parts requiring high resolution, accuracy and precision in the 2µm and 10µm resolution spaces. Now, we’re bringing that experience to an even wider range of end-use applications at the 25µm level,” said John Kawola, CEO of BMF. “While this printer is geared more toward industrial customers that need faster throughput, greater volume, and more automation, the result is still best-in-class part quality compared to other DLP platforms and we cannot wait to see what our customers accomplish with it.”

The announcement follows a funding round recently secured by the company to accelerate its growth.

Remember, you can post free of charge job opportunities in the AM Industry on 3D ADEPT Media or look for a job via our job board. Make sure to follow us on our social networks and subscribe to our weekly newsletter : Facebook, Twitter, LinkedIn & Instagram ! If you want to be featured in the next issue of our digital magazine or if you hear a story that needs to be heard, make sure to send it to contact@3dadept.com