UK-based expert in micro-precision industrial 3D printing, BMF, has announced two additions to its materials-printers combination.

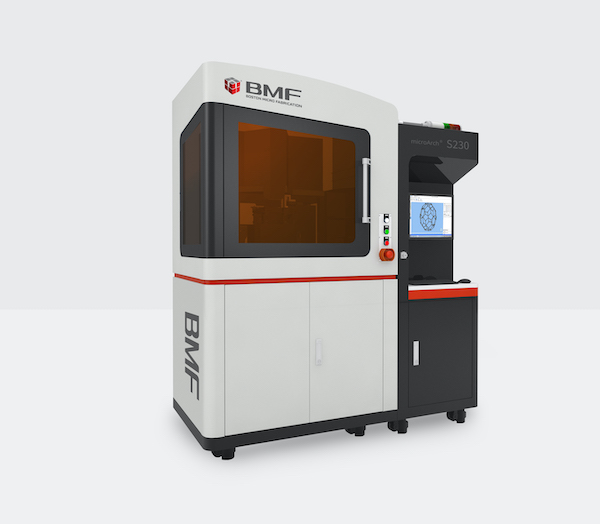

From the manufacturing side, the company has released the microArch™ S230, designed for applications that require ultra-high resolution prints (down to 2μm) with accuracy, precision, and speed.

With a larger built volume of 50x50x50mm, the printer is built upon BMF’s patented Projection Micro Stereolithography (PµSL) technology, a technique that allows for rapid photopolymerization of an entire layer of liquid polymer using a flash of UV light at micro-scale resolution. It delivers design freedom and part resolution, and could print up to 5 times faster prints than previous models in the 2μm series.

Ideal for researchers and manufacturers looking to print micro parts with tight tolerances from prototyping through production, the printer also supports ceramic 3D printing at the micro-level and can handle material viscosities up to 20,000 Cp.

This key feature is very timely as it will give users the opportunity to appreciate the new ceramic 3D printing materials that have just been released by the company. AL Alumina Ceramic and MT Magnesium Titanate Ceramic are interesting for applications that require hardness and high heat resistance.

“We’ve launched a new high temp material, HT 200 that can can withstand temperatures up to 200°C with high strength and durability, perfect for end use applications. Our new Alumina Ceramic material is perfect for applications involving tooling, casings and housings, and medical devices – able to withstand high temperatures with high strength properties and chemical resistance”, the company says in a press release about the Alumina AL Ceramic materials.

Key benefits of these materials include the ability to provide high-temperature, high strength, high stiffness, biocompability and chemical resistance.

Target applications/industries include tooling (injection molding), casings and housings, and medical devices.

“The combination of high dielectric constant and low dielectric loss make MT Ceramic suitable for millimeter wave applications such as antennas, wave guides, and other electronic components”, the company notes about the MT Magnesium Titanate Ceramic materials.

Those materials deliver dielectric properties (high constant, low loss) 100x lower than plastic alumina. Target applications/industries include communications and aerospace, waveguides, mm wave electronic components (sensors, radar cover, antenna, wave tuning components).

Remember, you can post job opportunities in the AM Industry on 3D ADEPT Media free of charge or look for a job via our job board. Make sure to follow us on our social networks and subscribe to our weekly newsletter : Facebook, Twitter, LinkedIn & Instagram ! If you want to be featured in the next issue of our digital magazine or if you hear a story that needs to be heard, make sure you send it to contact@3dadept.com