Just fourteen years ago, blockchain appeared onto the scene of the financial market as the power behind cryptocurrencies. Over time, the technology found its place within supply chains, but was limited to pilot projects until distributed manufacturing came into play. As applications are continuously being explored to advance this technology, one thing became certain: making blockchain and additive manufacturing converge is a great way to enable distributed manufacturing to thrive, but the transition to a circular economy can make this road a difficult one to scale. The article below aims to contribute to the Industry 4.0 literature by discussing the impact blockchain may have on additive manufacturing through the lens of circular economy.

Simply put, blockchain is a protocol for sharing and updating information by linking ledgers or databases in a decentralised, peer-to-peer, open-access network. This distributed ledger technology (DLT), which first emerged as a way of facilitating crypto-currencies, can lead to a powerhouse marriage when combined with other technologies. At the beginning, the whole idea of keeping manufacturing centralized has been based on the willingness to save costs and keep control but do you really keep control when supply chains are continually stretched to the point that trust is degraded?

Let’s take the example of a military aircraft: on the one hand, servicemen on the ground are frustrated because of delays and hurdles of the conventional aerospace supply chain, on the other hand, suppliers sometimes spend way too much time to get the digital rights-managed (DRM) part files of a crucial part – let alone the manufacturing time. This implies that without the digital rights-managed (DRM) part files, there is a risk that the file may be corrupted or tampered with upfront or that designers simply don’t know how many times a design might be printed once it is sold, or even that intellectual property can be stolen. This initial goal to save costs can therefore be aborted or can likely result in extra costs if the wrong files are purchased.

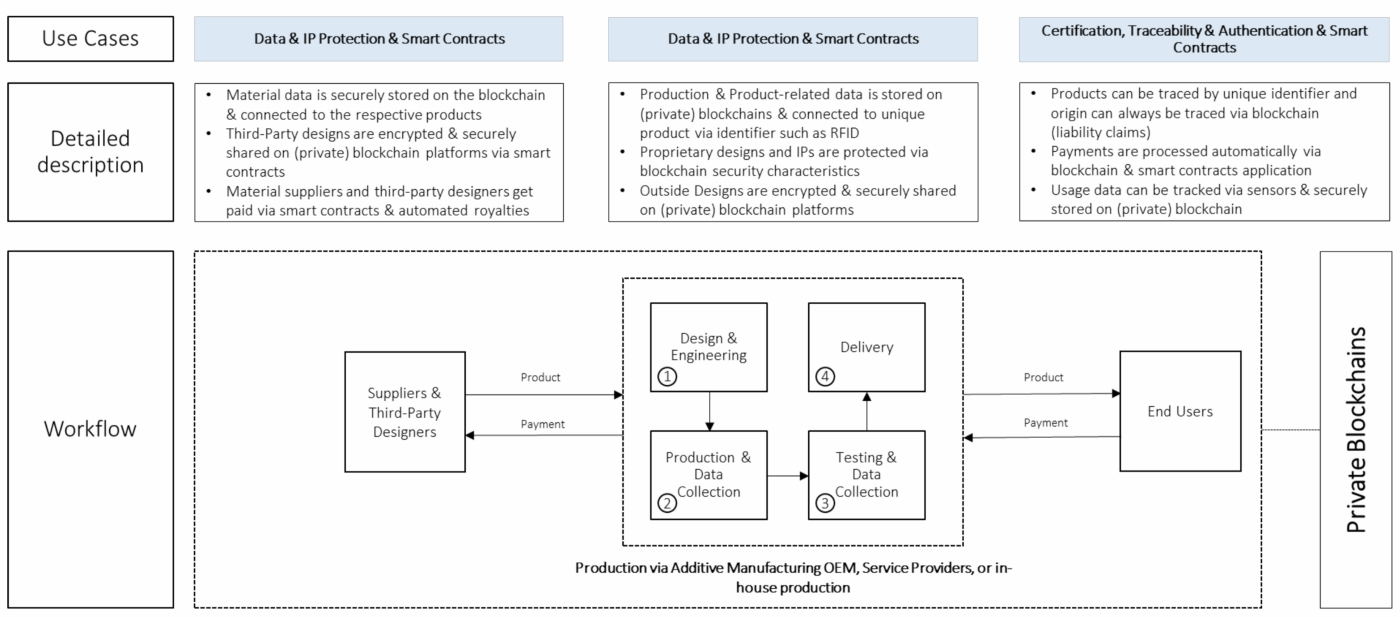

With all these issues popping up, part manufacturers, OEMs and stakeholders in vertical industries started exploring the use of blockchain as a miracle solution. Interestingly, the use of AM requires to explore that solution at multiple levels:

“Additive manufacturing is an ideal solution for rapid prototyping, producing spare parts, and to reduce transportation costs by decentralized manufacturing. The core problem is the prevention of illegal copies, because once you’ve obtained the printing file you can make as many copies as you want. This is where blockchain technology can offer a solution, so most of the technology’s use cases in the industry are therefore based on the prevention of illegal copies. This can be achieved in many ways. One is transparency. Serial numbers can be created on blockchain and integrated into the 3D model. Serial numbers on blockchain are unique by design, so any re-use can be excluded. If this measure alone is not sufficient, it can be propped up with “Track & Trace” on blockchain to follow the path of each printed part.

Another use-case involves the modification of the printer hardware or software (ideally both), so that it requires a “Token” of the design file for every printout.

Blockchain Technology also comes into play when the actual printing file is stored on a decentralized file system such as IPFS, and access rights are administrated by smart contracts. This can be a token or just some digital rights management based on cryptographic proofs.

Apart from prevention of illegal copies, blockchain can help to ensure the quality of a product. This is achieved by transparency too. Deriving a cryptographic fingerprint of data, a so-called “file hash” is key to ensure that a file is not tampered with. When you print a model, you want to make sure that no one has modified it, e.g. reduced or increased wall-thickness or support structures or has changed labels, logos, or other elements. Especially in the area of 3D printing in biotech and medical applications, this security is essential. Blockchain is the perfect tamper proof database, because it doesn’t allow any backwards-modification of data. Those are the most relevant use-cases to-date with an obvious economic benefit ”, Johannes Schweifer, CEO and Co-Founder of blockchain infrastructure company CoreLedger told 3D ADEPT Media. While the current focus is made on the use of blockchain in an AM production environment, CoreLedger’s blockchain platform can be used across various industries.

The company’s Token Economy Operating System (TEOS) provides all functionalities to build viable end-to-end use-cases, starting from documentation on blockchain, tokenization and accounting, to governance and trading. One of the most significant achievements of the company in this field is its partnership with Swiss company AMBITORIO AG with which it develops a solution for using blockchain to tokenize 3D print model files and thereby limit the number of copies that can be made.

While 3D printing equipment would need to be retrofitted to integrate blockchain, CoreLedger and Ambitorio can already integrate this solution. Photo Credit: Ambitorio.

While 3D printing equipment would need to be retrofitted to integrate blockchain, CoreLedger and Ambitorio can already integrate this solution. Photo Credit: Ambitorio.

The documentation features inherent to distributed ledger technology (DLT) can be used to ensure the authenticity of a file, while tokenization and accounting create a supply of file tokens and enable distribution on the built-in decentralized market, where those tokens can be traded.

If we dig a little bit further, Schweifer’s point of view underlines the fact that four distinct characteristics enable an effective integration of a blockchain technology:

- a distributed nature that enables stored data to be “distributed” (pun intended);

- a specific consensus mechanism that ensures the validity of transactions and new entries and removes the need for a central trust-building authority;

- the use of cryptographic measures and digital signatures to compel each stakeholder to prove their identity before a transaction is validated by the network;

- further security elements to enable traceability and verification.

Furthermore, we need to recognize that the digital nature of AM makes it a promising opportunity to integrate blockchain within a distributed Additive Manufacturing environment. Needless to say that real-life implementation differs from one use case to another, whether we deal with Data & IP protection, traceability, authentication and certification, smart contracts, and process automation.

Moreover, the combination of challenges raised by each of these use cases also hinders the scalability of the technology within an AM environment – not to mention their cost implications. Emphasizing on some of the challenges and solutions on this road, Schweifer notes:

“First, there is the technical hurdle. Effective copy-protection requires a hardware and software modification. The model itself is just bits and bytes, and there are plenty of ways how to steal it without any blockchain authorization. End-to-end encryption plays an important role here. The second hurdle is the transparency itself. Not every industry is ready for total openness when it comes to providing information about the whereabouts of the printed products. Geolocations, a person’s identity, and even company names could be sensitive. This is especially true in medical and biotech applications. Cryptography can be used to obfuscate the data, but this would reduce transparency. The underlying blockchain is also a challenge. Many proposed solutions are based on Ethereum technology, but they were written when transactions on the Ethereum blockchain were cheap.

[Ethereum is a large blockchain ecosystem.]

“When the gas limit became a problem, transactions became quite pricey. It wouldn’t be economical to pay 30 or 40 USD just to create a serial number on Ethereum. Apart from Ethereum, there are many other choices, but that’s exactly the problem. How can you avoid running into the same cost-problem (…) And which blockchain to choose? In the absence of an industry standard, there is no easy “blockchain of choice” either, and that’s before we get to the question of whether it should be a public or private chain. These questions have to be addressed on a case-by-case and company-by-company basis, depending on their specific requirements. Then there are some practical hurdles. If we assume that the number of copies are limited by the number of tokens, then each token represents the right to print exactly one copy. But 3D printers don’t have a 100% success rate, especially not with complex geometries. Token-based approaches therefore require an automated quality check, which can grant a refund”, he continues.

This number of questions makes it difficult to envision a blockchain-enabled business model in AM – let alone one that complies with sustainability.

Can a blockchain-enabled business model comply with sustainability?

CoreLedger’s representative raises a number of questions that are worth exploring for companies that are looking to integrate blockchain into their production environment. From a manufacturing and IP protection standpoint, I guess there isn’t much to say anymore. The CEO made it clear that the right process lies in the trust the user has in the token and not in the buyer.

CoreLedger’s representative raises a number of questions that are worth exploring for companies that are looking to integrate blockchain into their production environment. From a manufacturing and IP protection standpoint, I guess there isn’t much to say anymore. The CEO made it clear that the right process lies in the trust the user has in the token and not in the buyer.

From a profitability standpoint, the integration of blockchain can be appealing to local manufacturing businesses. While a consortium of companies affirms they have been able to integrate blockchain within a cross-continent distributed Additive Manufacturing environment, I remain very cautious about such deployment given the fact that we still lack viable benchmarks.

In addition, local manufacturing can also bring to the table the benefits of sustainability we probably all know already: local production = less transportation, therefore less CO2 emissions and on-demand production. To this argument, Schweifer adds:

“It must be possible to recycle 3D printed parts into raw material. Thermoplastics are the most viable material for this purpose, which excludes already some additive techniques. Blockchain Technology comes into play when Track & Trace mechanisms can be used to reward the returning of broken or retired parts into the product cycle. Products can, for example, be labelled with serial numbers and when they are recycled, the serial number is invalidated and some reward tokens are paid, which in turn are used at the beginning of the product cycle, to e.g. pay for printing runs (new serial numbers) or raw materials”.

This argument may be valid but here again, I remain cautious because of another counter-argument: the goal of finding a balance between preserving safety measures and “greenness” is a hard one to strike, thus the technology has earned a bit of a bad reputation for implementing a consensus mechanism that’s energy-intensive.

We should recognize the fact that, there are a few different varieties of these consensus algorithms to choose from, some of which are better than others. Those consensus mechanisms include Proof of Work (PoW), Proof of Stake (PoS) and Proof of Authority (PoA). It’s up to the user to have a clear understanding of each of them in order to determine what they have to compromise on.

“The current market of blockchain and AM is still in its infancy, with many ideas and projects. Blockchain technology has just overcome its days of extreme hype. NFTs and Tokens overshadowed every alternative use-case for the technology during the past years, drying up funding for non-financial projects. Blockchains kept emerging as well, making earlier implementations on costlier or slower blockchains obsolete. This naturally hampers progress.

Nonetheless, there is now growing interest from the industry. Blockchain technology can ultimately help to save money or to prevent loss, e.g. from illegal copies. That’s certainly not negligible in terms of economic value. The value for blockchain in Additive Manufacturing is clear: To solve the problem of copy-protection (some form of digital rights management, essentially). Blockchain technology is the perfect tool to prevent copies and counterfeits, therefore it is a natural fit for the task. Once designers of 3D models feel safe to publish their files on a blockchain-based digital-rights platform without reluctance, because they know their intellectual property is protected from illegal use, then we’d have achieved a major milestone”, Schweifer concludes.

This dossier has first been published in the September/October edition of 3D ADEPT Mag.

Remember, you can post jobopportunities in the AM Industry on 3D ADEPT Media free of charge or look for a job via our job board. Make sure to follow us on our social networks and subscribe to our weekly newsletter : Facebook, Twitter, LinkedIn & Instagram ! If you want to be featured in the next issue of our digital magazine or if you hear a story that needs to be heard, make sure to send it to contact@3dadept.com