A wide range of entry-level 3D printers exists for desktop 3D printers, but the market is not that much fulfilled for those who would like to take their first steps in large-format additive manufacturing.

To address this need, Thermwood has just unveiled a new line of lower cost “print only” LSAM systems, called LSAM Additive Printers.

Why would this expert in large format 3D printing build an entry-level LSAM system when he already has a portfolio already well fulfilled?

To meet the “requests for a somewhat smaller, lower cost additive system which still has all the features and print quality of the large flagship LSAM systems”, the company says. From now on, the team also provides a line of “print only” machines.

About the LSAM Additive Printer

As a reminder, the existing line of Thermwood’s portfolio is made up of large scale, dual gantry, “print and trim”, near-net-shape additive manufacturing systems that delivers parts from various materials including reinforced composite thermoplastic polymers, as well as materials like PSU, PESU, and PEI that require high temperatures.

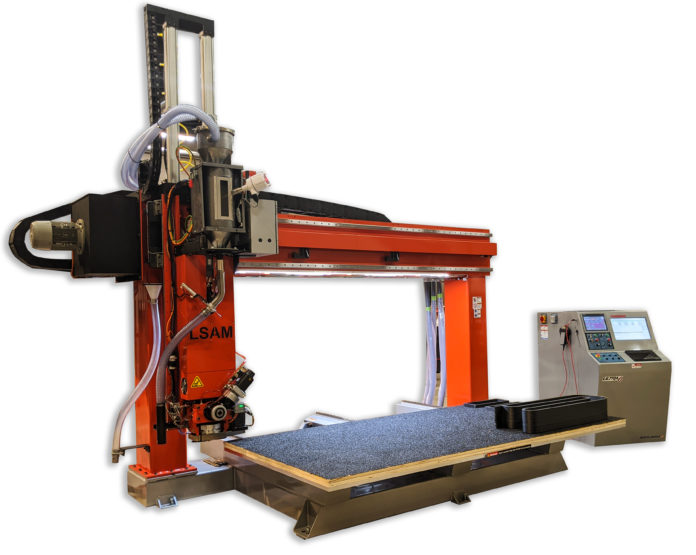

Unlike other machines that are equipped with 40-60mm print heads, the new “print & only” system is equipped with a new 30 mm print head. To meet the performance requirements experienced with other 3D printers, the team at Thermwood re-engineered the gantry structure of its acknowledged 5 axis CNC routers so that the machine achieves a similar “slot and tab” structural steel approach than other machines.

The new print head can deliver up to 100 pounds (45kg) per hour – compared to 500 pounds (227) for the other machines-, and can produce large parts at temperatures up to 450° C.

The manufacturer ensures that the LSAM Additive Printers are all fixed gantry, moving table designs with table sizes of 5’x5’ (13×13 cm) and 5’x10’ (13x25cm) and are capable of printing parts up to 4’ (10cm) high. Maximum table print weight is 1,000 pounds (453kg), however, the 10’ (25cm) wide 5’ (13cm) deep machine is available with a dual servo drive which doubles the weight carrying capability. It is planned to equip the 5’ (13cm) wide 10’ (25cm) deep version with a Vertical Layer Printing option which will allow it to vertically print parts up to ten feet tall.

All patented additive print features such as the control feature that are found in other machines have also been included in this one, alongside the recently unveiled Thermal Sensor Layer Automation System and a system for drying and conveying pelletized polymer material. The latter is a liquid chilling system that reveals its importance when dealing with high temperature materials as its helps maintain temperature control on vital systems.

Other options that come with the 3D printer include the enclosure and the dual hopper dryer.

“This new LSAM Additive Printer is intended to introduce LSAM additive technology to a whole new level of application and customer. It targets companies that want to print top quality, large composite thermoplastic parts, but don’t really need, nor can they cost-justify, the really large LSAM systems. These new systems also target companies who already have sufficient trimming capability and may only need a quality print function. Applications include industrial fixtures, molds (including high temperature molds), tooling, foundry patterns, and hundreds, if not thousands of similar applications”, Thermwood concludes.

Remember, you can post job opportunities in the AM Industry on 3D ADEPT Media free of charge or look for a job via our job board. Make sure to follow us on our social networks and subscribe to our weekly newsletter : Facebook, Twitter, LinkedIn & Instagram ! If you want to be featured in the next issue of our digital magazine or if you hear a story that needs to be heard, make sure to send it to contact@3dadept.com