Remember Arris? The tech company behind Additive Molding™, a high-speed manufacturing process that aligns continuous carbon fibers and enables the integration of electronic components and multifunctional materials into a single topologically optimized part or component.

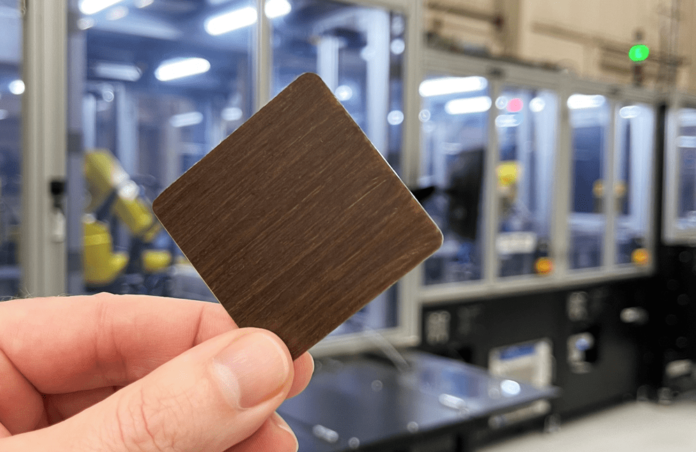

The R&D team has developed natural-fiber composites with high-performance capabilities to complement its already available bio-nylon resin material being used with carbon and glass fiber.

The announcement follows another milestone the company recently hit: the expansion of its Additive Molding production capacity to 1M+ parts on the heels of a partnership signed with a contract manufacturer in Malaysia.

As far as the fiber material solution is concerned, the company explained that since flax fiber is <5% of the CO2e footprint compared to carbon fiber, these advanced composites have a massive impact on further reducing CO2 emissions.

“Since we started, our R&D team has been researching and investigating recycled, recovered, and natural fibers, as well as recycled, bio-based, and bio-synthesized polymers that help brands achieve necessary sustainability initiatives without sacrificing the best-in-class performance their customers have come to expect,” said Bert Mannhalter, ARRIS Vice President of Research and Development. “I’m excited to reach this breakthrough in processing flax fibers. Though it’s been used for cosmetic parts such as veneers and paneling, we now see a way to use these fibers for true structural applications.”

Users who are interested in Arris’ solution include brands in portable electronics, footwear, sporting goods, transportation, and industrial industries.

Remember, you can post free of charge job opportunities in the AM Industry on 3D ADEPT Media or look for a job via our job board. Make sure to follow us on our social networks and subscribe to our weekly newsletter : Facebook, Twitter, LinkedIn & Instagram ! If you want to be featured in the next issue of our digital magazine or if you hear a story that needs to be heard, make sure to send it to contact@3dadept.com.