Industrial 3D printer maker, AON3D introduces a new high temperature 3D printer Hylo™ along with the additive manufacturing software Basis™, adding to the portfolio of high-performance printers enhanced with 3D filaments from Kimya launched earlier in January.

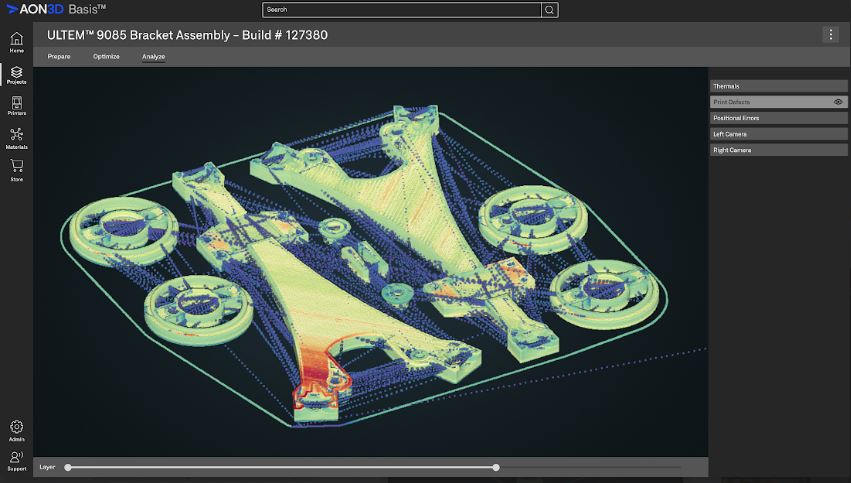

The new 3D printing software Basis™ is equipped with machine learning driven thermal optimization, process simulation and part qualification tools which along with the 3D printer Hylo™ would expedite the 3D printing process of polymers and carbon fiber composites. According to AON3D, the system can print materials with extreme chemical resistance and continuous temperature up to 260°C.

The new AON3D printer

The Hylo™ 3D printer has a build area of 25.6 x 17.7 x 17.7 inches (65.02 x 44.95 x 44.95 cm) and a 250°C chamber. With more than 8x throughput, the new AON3D printer can go up to a speed of 500 mm/s and have IDEX-enabled duplication/support modes.

The Hylo™ 3D printer is described as a “smart” 3D printer that has advanced process control and monitoring, integrated with over 25 sensors. The machine is backed by thermal optimization software. These features help the AON3D printer to make strong AM parts as it continuously monitors and controls the process, and compensates for process variability.

Through the launch of Hylo™, AON3D is trying to address the issues of high-performance polymers like PEEK and ULTEM™ as the antiquated open-loop hardware or software of most printers can’t effectively use the materials. The slicers of the 3D printers don’t have material-specific thermal awareness to control and monitor the system. Also, the absence of feedback loops makes it difficult to use PEEK and ULTEM™ 3D printing material.

Most printers tackle these problems by reducing variability through locking down materials and process settings to “one size fits all” print speeds and thermals, resulting in print failures and hidden defects in the 3D printed parts.

AON3D integrates Hylo™ with Basis™ software, adding material awareness into the slicing process.

The new thermal awareness software

The future of AON3D printers lies in Basis™ which has intelligent-slicing and in-process monitoring, turning process variability into part confidence with just a few clicks. The software adds material-specific thermal awareness to the Hylo™ slicing process. This helps in optimizing properties like dimensional accuracy, surface finish and later weld strength.

Users can also verify the quality of the AM parts through the Hylo process monitoring data which captures over or under-extrusion, filament diameter variances, warping or cracking, debris inclusion and hidden defects.

Remember, you can post job opportunities in the AM Industry on 3D ADEPT Media free of charge or look for a job via our job board. Make sure to follow us on our social networks and subscribe to our weekly newsletter : Facebook, Twitter, LinkedIn & Instagram ! If you want to be featured in the next issue of our digital magazine or if you hear a story that needs to be heard, make sure to send it to contact@3dadept.com