This is probably not the first topic that will come to one’s mind when talking about net zero, but Evove, a UK-based company is operating on a market that I find intriguing: filtration technology. Correction: the field itself is not intriguing but the role it can play to achieve net zero mission goals is, add to that the fact that Additive Manufacturing can be part of the equation, well the team sparked my interest.

Put simply, Evove is on a mission to reduce the cost and environmental impact of the filtration and separation of fluids in a variety of sectors. By filtering the unfilterable, the team leverages nanotechnology and additive manufacturing processes to deliver advanced membrane technology that could reduce the impact of water filtration.

How does water filtration hamper sustainability or the environment at scale?

A lot of considerations need to be taken into account.

Water filtration systems affect the environment through production, testing and transport. These issues are present in any product that’s manufactured and shipped to customers. Manufacturing of water purification systems requires a lot of material and water from a wide variety of different sources. Depending on the specific types of materials that are used, the degree of the impact on the environment varies, one learns from a source.

On another note, industrial process water is not (that) easy to recycle; not to mention that there is often waste in wastewater, and cleaning up heavy industry wastewater lakes is not that simple. Evove has taken note of all these challenges and now ambitions to address them by targeting the lithium, green hydrogen, desalination, food and beverage, and water and wastewater industries.

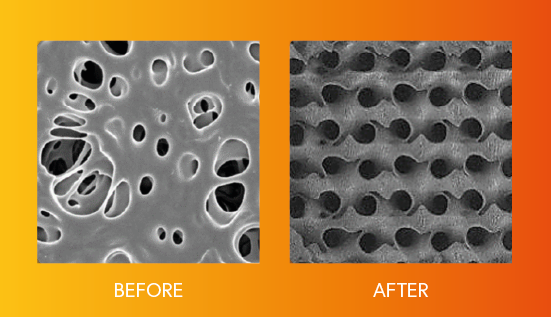

More specifically, the company’s technology harnesses graphene oxide based coatings and a variety of 3D-printed enhancements to boost the performance of conventional membranes. Separonics® are Evove’s precision-engineered membranes, providing transformational productivity gains in selectivity and flux, operational efficiency, energy consumption and equipment lifetime.

Next steps with the completion of a funding round of £5.7 million

With a new funding round led by At One Ventures, and the participation of AM VC firm AM Ventures, the company also received support from existing investors.

Chris Wyres, CEO of Evove Ltd commented, “We are thrilled to have received support from At One Ventures and AM Ventures in addition to further investment from our existing investors. This funding will enable us to increase manufacturing capacity and expand our service and support network, enabling us to help end-users solve some of the world’s biggest water and energy challenges.”

Evove will now establish new manufacturing facilities in the north-west of England will create high-value jobs and economic growth in the region.

Johann Oberhofer, Managing Partner at AM Ventures, said, “We are convinced that Evove is a prime example of how additive manufacturing can transform our world and significantly reduce CO2 emissions in many areas. We back trailblazing entrepreneurs in 3D printing and Evove are at the forefront of precision engineered filtration membranes that will significantly disrupt the status quo in their markets.”

There is no doubt Evove is up to something interesting. We are now waiting for applications and data that could confirm it.

Remember, you can post free of charge job opportunities in the AM Industry on 3D ADEPT Media or look for a job via our job board. Make sure to follow us on our social networks and subscribe to our weekly newsletter : Facebook, Twitter, LinkedIn & Instagram ! If you want to be featured in the next issue of our digital magazine or if you hear a story that needs to be heard, make sure to send it to contact@3dadept.com