Yizumi is a large machine manufacturer who develops and commercializes a wide range of manufacturing equipment that range from injection molding of polymers and metals, robotic arms and extruders, to 3D printing.

In this latter category, the company integrates an industrial 3D printer named SpaceA which combines several technologies into one. Designed for continuous production of polymer parts, the machine processes pellets that are deposited layer by layer by a robotic system. Those conventional thermoplastic pellets allow for printing with highly filled compounds. The 3D printer can also print resins reinforced with carbon fibers.

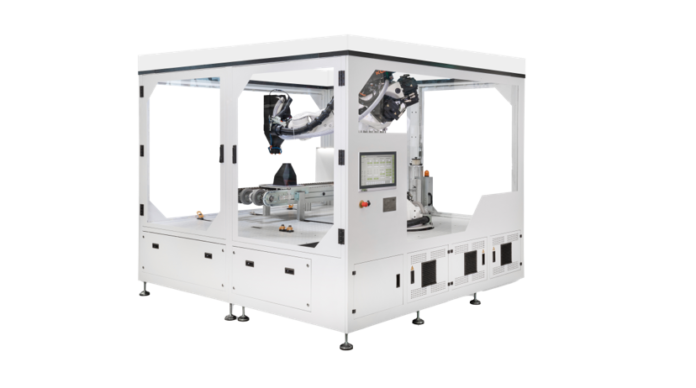

The system can come in three configurations: an extruder extension package (a dryer, material conveyer, screw extruder and a control unit for pneumatic and electrical components), a small machine package (which includes the extruder package + an industrial robot and a housing) and a big machine package.

This robot automatic system can also perform vision-guided detection for complex composite materials. When the plastic parts are in place, the vision system collects and intelligently analyzes the data of each piece of goods to determine the correct side and accurate position of them first.

The SpaceA’s print head moves with positioning accuracy to within 0.05mm. The system is packaged with control technology, including an 18.5-inch multicolor display.

The machine comes with a belt feature as an option. This belt enables the machine to produce parts continuously. As the belt moves forward, prints peel off the belt and fall into a collection bin for further processing.

Amid the industries that could explore this solution, Yizumu puts household and automotive applications forward; applications that could be achieved in low volume quantities. Applications for the SpaceA system include applying sealing elements or reinforcing structures to injection molded parts.

Given its existing expertise, it won’t be a surprise to see industrials with injection-molding capabilities as the first target of this equipment.

Remember, you can post free of charge job opportunities in the AM Industry on 3D ADEPT Media or look for a job via our job board. Make sure to follow us on our social networks and subscribe to our weekly newsletter : Facebook, Twitter, LinkedIn & Instagram ! If you want to be featured in the next issue of our digital magazine or if you hear a story that needs to be heard, make sure to send it to contact@3dadept.com