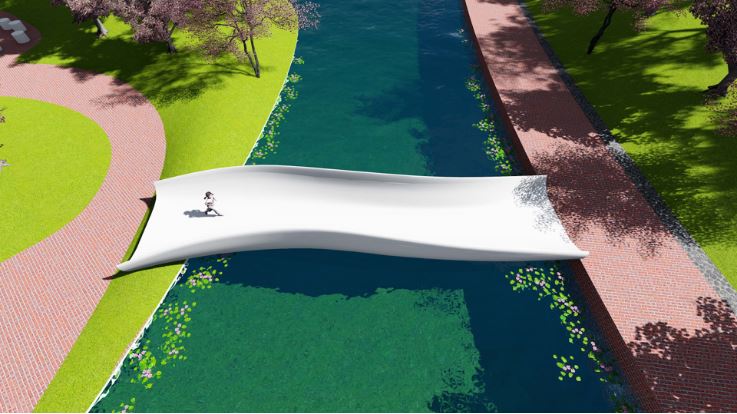

In order to demonstrate the capability of their new 3D system, the Shanghai Construction Group will build a 3D printed Pedestrian Bridge.

A large plastic 3D printer

$2.8 Million USD. That’s the amount that was invested by the Shanghai Construction Group to manufacture the 3D printer.

Built by Shenyang Machine Group in July 2018, the system integrates both an additive and subtractive process. With a printing volume of 144 cubic meters, it is possible to adjust the configuration of the extruder in order to increase the size of the room and double the Z axis print height from 1.5m to 3m.

Coin Robotic and Polymaker took part in the construction of the machine. Coin Robotic fabricated the extruder and Polymaker has provided the required materials. For the record, this project is just another example of how Polymaker’s materials can be used in manufatcuring. The latest interesting project unveiled by the company was the car built in collaboration with XEV.

How is the bridge going to be manufactured?

Weighing in at 5.8 metric tons, the bridge will be 100% printed plastic. Its manufacturing is supposed to end this December.

Manufacturers will use ASA (acrylonitrile styrene acrylate), an industrial material with 12.5% glass fibres (by weight) that presents good weather resistance, great toughness, thermal stability and chemical resistance. In addition to the strength it brings, the glass fibres enable to reduce the warping effect noticed when printing in such large volumes.

Encountered challenges

In addition to warping that has been solved by glass fibres, the teams tackled issues such as heat retention, layer levelling and bed adhesion.

As far as layer levelling, the extruder features a cam powered layer leveller which pats down the ASA immediately after extrusion. This ensures that every layer is completely level over an area of 96m2. This has greatly improved the repeatability and accuracy of the printer, whilst ensuring a very strong chemical interlayer bond.

As for bed adhesion, to adhere the first layer of the print, ASA pellets are glued to wooden boards and the wooden boards are clamped to the steel plates that make up the bed of the printer.

The bridge will be installed into a park in downtown Shanghai, where it will serve as a pedestrian crossing over a small lake.

For further information, follow us on our social media and subscribe to our newsletter!

Would you like to be featured in the next issue of our digital magazine? Send us an email at contact@3dadept.com

//pagead2.googlesyndication.com/pagead/js/adsbygoogle.js

(adsbygoogle = window.adsbygoogle || []).push({});