3Diligent added silicone 3D Printing to its capabilities. Now, the rapid manufacturing services provider can accept requests for quote (RFQs) and processes orders in the material.

“Being able to 3D print silicone is an exciting innovation. At 3Diligent we strive to meet the 3D Printing needs of all designers and are pleased to expand our range of elastomeric materials with silicone,” said 3Diligent CEO Cullen Hilkene.

Thanks to Silicone 3D Printing, it is now possible to observe innovative product development in a great number of industries.

The medical industry is part of those industries which will benefit a lot from silicone printing. Indeed, from realistic silicone models for surgical training to 3D printed bandages applied directly to human skin to exploration of artificial hearts, silicone 3D Printing’s capacities are required in medicine where they can alter and save lives

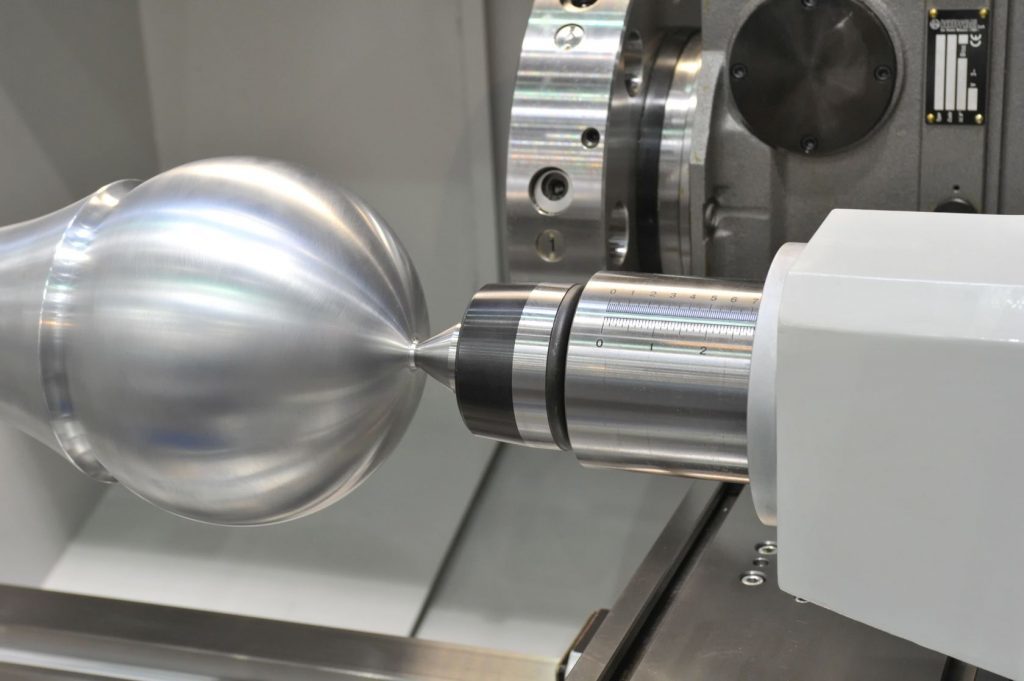

As part of the additive materials and processes that 3Diligent will deliver, one includes 3D Printing, CNC Machining, and Molding and Casting across hundreds of machines and materials.

When submitting an RFQ on the 3Diligent website for silicone 3D Printing, designers will use the same streamlined process as for other materials and processes. Customers can log onto the secure 3Diligent.com portal, upload their CAD design files, and type silicone as their desired material. Using its proprietary software, 3Diligent will identify the optimal silicone fabrication solution, issue a quote, and fulfill the order upon acceptance.

For further information about 3D Printing, follow us on our social networks!

//pagead2.googlesyndication.com/pagead/js/adsbygoogle.js

(adsbygoogle = window.adsbygoogle || []).push({});