Machine manufacturer and parts producer 3DEO, has added the 316L austenitic stainless steel to its portfolio designed for high volume metal 3D printing. Ideal for applications across all industries, especially in medical, industrial, marine and food processing, the fully austenitic, non-magnetic stainless steel, 316L (equivalent to UNS S31603) is said to deliver excellent performance at room and moderately elevated temperatures, as well as excellent ductility and mechanical performance. This weldable material is extremely corrosion resistant, which makes it ideal for applications that will experience harsh environments.

“With material properties that meet the MPIF Standard 35 standards, introducing 316L to our customers will allow them to take advantage of the benefits, time-savings and cost-efficiencies of 3D printing using a biocompatible, corrosion-resistant material like 316L for their high-demand applications”, said Matt Petros, CEO and co-founder of 3DEO

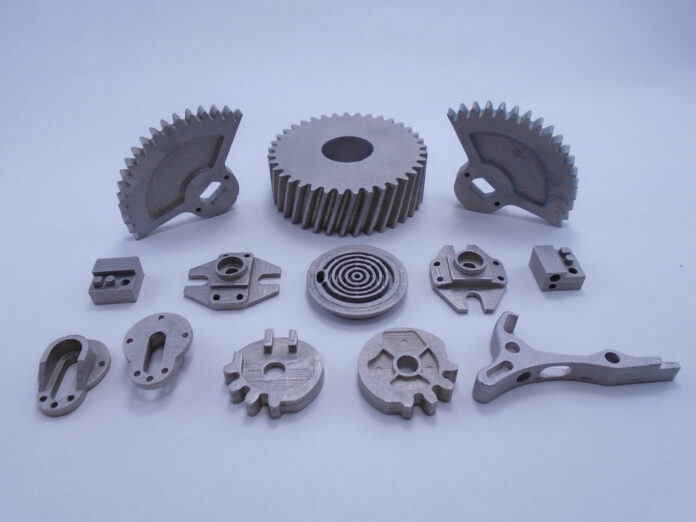

316L is commonly used in applications such as laboratory equipment, impellers and pumps, engine parts, food processing equipment, jewelry, kitchen appliances, surgical instruments, marine, chemical and petrochemical processing, and more.

3DEO helps customers with their complex metal components at every stage of the product life cycle, from early ideation and prototyping to manufacturing at scale. And because prototypes are manufactured using the same machines and technologies as longer production runs, with 3DEO, customers can seamlessly progress from prototype to production without the need to undergo lengthy or costly design changes or requalification to launch products.

“We partner on the design and prototyping to prove novel designs. Then, after the necessary product testing is complete, 3DEO can get them into production faster than any other metal production technology”, CTO Payman Torabi comments.

316L completes a portfolio that already includes 17-4PH stainless steel. Other materials – currently under testing, are set to be released along the year. Stay tuned.

Remember, you can post job opportunities in the AM Industry on 3D ADEPT Media for free or look for a job via our job board. Make sure to follow us on our social networks and subscribe to our weekly newsletter: Facebook, Twitter, LinkedIn & Instagram ! If you want to be featured in the next issue of our digital magazine or if you hear a story that needs to be heard, make sure you send it to contact@3dadept.com