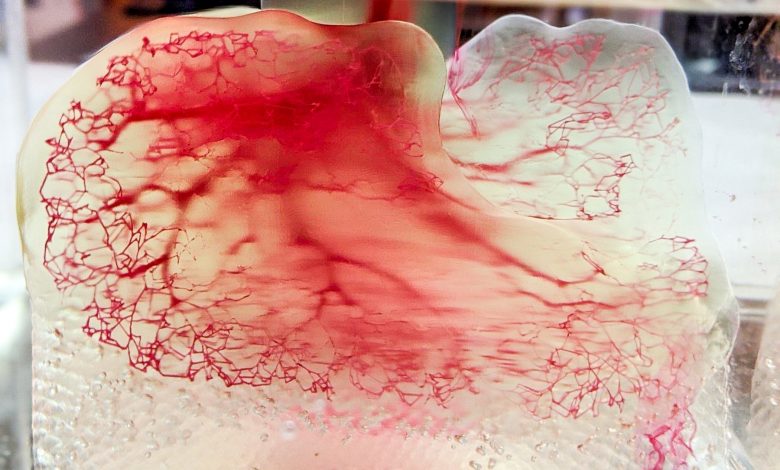

Ever since they have announced their partnership, 3D Systems and United Therapeutics have invested extra miles in the development of human lung scaffold. With the goal of creating a substantial supply of lungs ready to replace transplants, the partners have reached a milestone in their collaboration as they unveiled a fully printed human lung scaffold at this year’s CNN-sponsored Life Itself conference.

Described as the world’s most complex 3D-printed object, the human lung scaffold designs consisted of a record 44 trillion voxels that lay out 4,000 kilometers of pulmonary capillaries and 200 million alveoli.

Scientists at United Therapeutics plan to cellularize these 3D-printed scaffolds with a patient’s own stem cells to create tolerable, transplantable human lungs that should not require immunosuppression to prevent rejection, a press release explains.

“Last week, it was exciting to show the public our 3D-printed human lung scaffold, but we’re thrilled to share that our 3D-printed lung scaffolds are now demonstrating gas exchange in animal models. We are regularly printing lung scaffolds as accurately as driving across the United States and not deviating from a course by more than the width of a human hair,” said Dr. Martine Rothblatt, United Therapeutics’ Chairperson and Chief Executive Officer. “With the continued hard work of dedicated scientists and engineers at United Therapeutics and 3D Systems, we hope to have these personalized, manufactured lungs cleared for human trials in under five years.”

Given the fact that over 100,000 people are waiting for lifesaving organ transplants – every 9 minutes another person being added to the US transplant waiting list – , it’s essential to work towards the ultimate goal of creating an unlimited supply of transplantable lungs.

According to Dr. Rothblatt, today, a process called ex-vivo lung perfusion is currently used to add to the supply of transplantable lungs by extending by several hours the period of assessment and viability for human donor lungs, resulting in over 230 lives extended to date.

“The reveal at LIFE ITSELF represents the culmination of our efforts with United Therapeutics that includes not only 3D-printed lungs, but two additional organs under development, kidneys and livers,” said Chuck Hull, 3D Systems’ Co-Founder, Executive Vice President, and Chief Technology Officer for Regenerative Medicine. “These lung designs can be printed in as little as three weeks using our latest advanced photopolymer-based bioprinting technology we call Print to Perfusion.”

Remember, you can post job opportunities in the AM Industry on 3D ADEPT Media free of charge or look for a job via our job board. Make sure to follow us on our social networks and subscribe to our weekly newsletter : Facebook, Twitter, LinkedIn & Instagram ! If you want to be featured in the next issue of our digital magazine or if you hear a story that needs to be heard, make sure you send it to contact@3dadept.com