This will be a premiere in the engineering world. Researchers from the Hebrew University of Jerusalem have developed a new method for 3D printing wooden structures that change shape as they dry. The process could inspire some innovative design in the manufacture of furniture. According to the researchers working on this project, this technique could be used to make furniture or other wooden products that could be shipped flat to a destination and then dried to form the desired final shape.

The traditional manufacturing process of wooden objects implies sawing, carving, bending or pressing. With 3D printing, flat wooden shapes can be programmed to self-morph into complex 3D shapes.

In nature, plants and some animals can alter their own shapes or textures. Even after a tree is cut down, its wood can change shape as it dries. It shrinks unevenly and warps because of variations in fiber orientation within the wood. “Warping can be an obstacle,” says Doron Kam, a graduate student who is presenting the work at the meeting, “but we thought we could try to understand this phenomenon and harness it into a desirable morphing.”

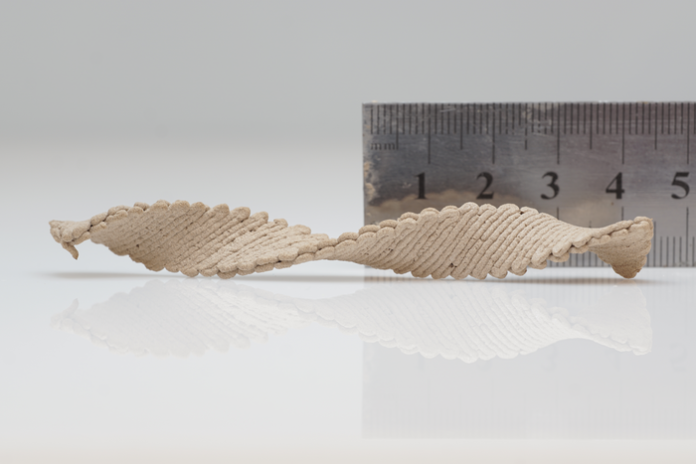

The idea of the research started a few years ago when the team developed an environmentally friendly water-based ink composed of wood-waste microparticles known as “wood flour” mixed with cellulose nanocrystals and xyloglucan, which are natural binders extracted from plants. The researchers then began using the ink in a 3D printer. They recently discovered that the way the ink is laid down, or the “pathway,” dictates the morphing behavior as the moisture content evaporates from the printed piece. For instance, a flat disk printed as a series of concentric circles dries and shrinks to form a saddle-like structure reminiscent of a Pringles® potato chip, and a disk printed as a series of rays emanating from a central point turns into a dome or cone-like structure.

The ultimate shape of the object can also be controlled by adjusting print speed, the team found. That’s because shrinkage occurs perpendicular to the wood fibers in the ink, and print speed changes the degree of alignment of those fibers. A slower rate leaves the particles more randomly oriented, so shrinkage occurs in all directions. Faster printing aligns the fibers with one another, so shrinkage is more directional.

Further refinement will allow the team to combine the saddles, domes, helices and other design motifs to produce objects with complicated final shapes, such as a chair. Ultimately, it could be possible to make wood products that are shipped flat to the end user, which could reduce shipping volume and costs, Kam says. “Then, at the destination, the object could warp into the structure you want.” Eventually, it might be feasible to license the technology for home use so consumers could design and print their own wooden objects with a regular 3D printer, Sharon says.

The team is also exploring whether the morphing process could be made reversible. “We hope to show that under some conditions we can make these elements responsive — to humidity, for example — when we want to change the shape of an object again,” Sharon says.

The full research can be found here.

Remember, you can post job opportunities in the AM Industry on 3D ADEPT Media free of charge or look for a job via our job board. Make sure to follow us on our social networks and subscribe to our weekly newsletter : Facebook, Twitter, LinkedIn & Instagram ! If you want to be featured in the next issue of our digital magazine or if you hear a story that needs to be heard, make sure you send it to contact@3dadept.com