Six years ago, the new modus operandi of Fairphone, a creator of “fair products”, raised attention. “Manon, a young girl, receives 3 SMS, notifying her that the local factory had started the cover of her phone. A unique cover, specifically designed for her with the help of a 3D printer. It took 2 hours to manufacture the cover based on the given specifications. Eager to receive her new purchase, Manon chose the local factory because it generates the cheapest carbon cost, and the delivery man being in the neighborhood, it makes no doubt she would have received her mobile phone’s cover as soon as it would be ready.” Fiction or not, Manon’s story raises questions about today’s market. It is no secret that on-demand production has almost become the “basic service” for a wide range of 3D printing companies. So, what is the impact on the supply chain, on its players? And how far the modus operandi has evolved for manufacturers and end consumers?

3D printing, disruptive element in the supply chain or accelerator of turnover?

An accurate answer to this question requires to consider all stakeholders in the supply chain.

For a long time, the “Made in China” has meant low prices for industrial manufacturers. 3D Printing has been a game changer for those who have taken advantage of its potential. Industrials who do not master the technical aspect of the technology partnered with 3D printing companies to ensure the fabrication of their products. Such partnerships often result in limited collections of 3D printed products from renowned brands.

Famous shoe brand adidas has for instance partnered with 3D printing company Carbon to produce a limited collection of AlphaEDGE 4D LTD sneakers using the company’s proprietary technology. In the same vein, Morel relies on Initial, just as Safilo relied on Materialise for the production of their 3D printed eyewear collection.

Supply chain management at an industrial 3D printing service company

We reached out to Protolabs, provider of industrial 3D printing services, in order to know how the company ensures the management of its supply chain, since it integrated 3D printing into its offering.

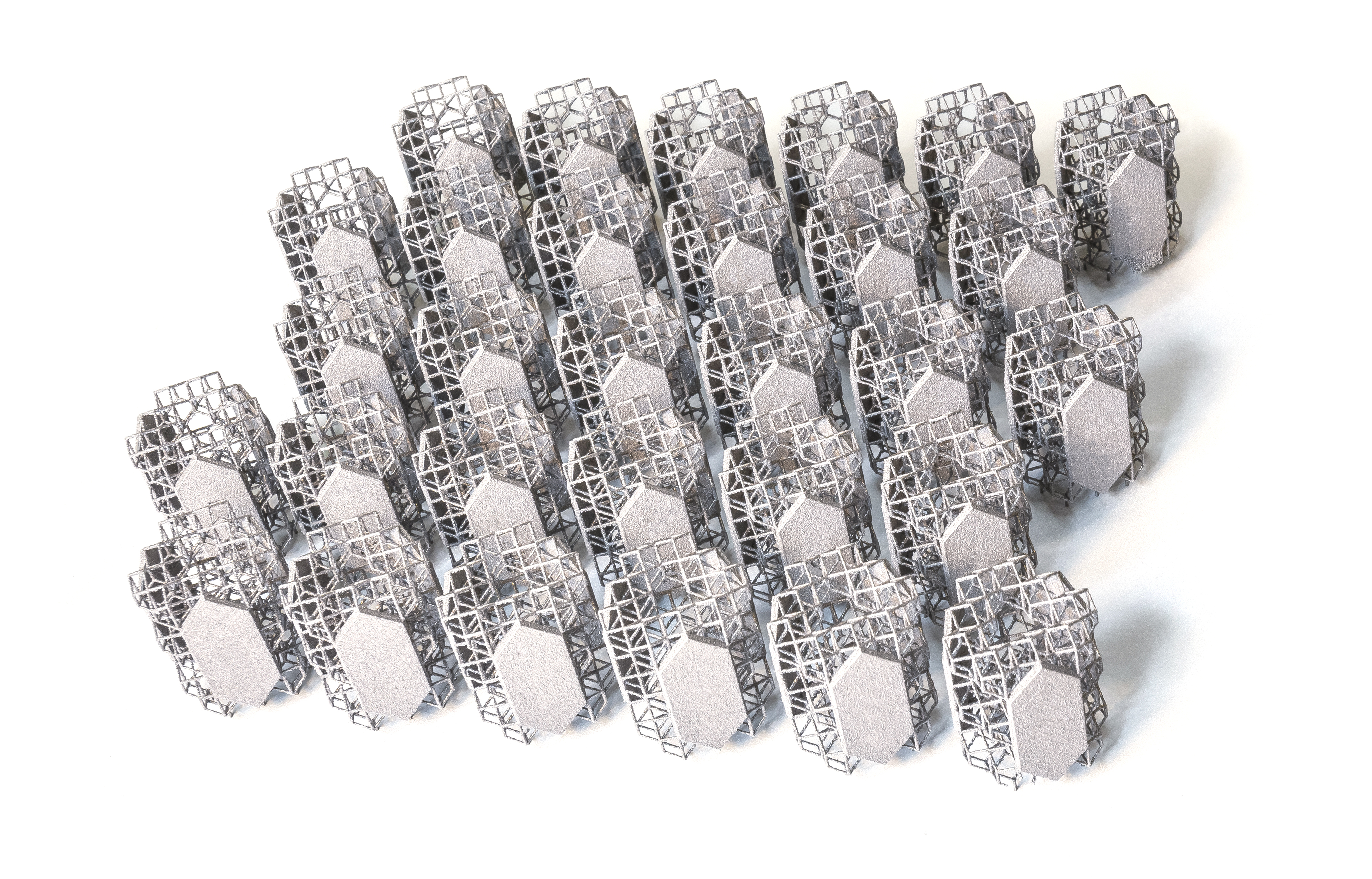

Protolabs manufactures custom-prototypes and on demand production parts. They first used injection moulding and CNC machining in their manufacturing processes. In 2015, the company integrated industrial 3D printing into its offering and expanded its range of technologies to SLA, SLS, DMLS, MultiJet Fusion, Polyjet and Silicone 3D printing.

According to Solideth Chang, Sales manager in the company, “supply chain management is strategic to secure companies’ growth and profitability: it mitigates risks in product development, may prevent disruptions and enables to maximise opportunities. In other words, in the field of product development, optimised supply chain accelerates time to market and provides a quick response to the endless changes, while in the field of on-demand manufacturing, it handles threats, and opportunities.

Partnering with suppliers that leverage technology and process excellence to expedite responses and deliveries is crucial in the successful implementation of a good supply chain.”

Talking about the use of 3D printing in supply chain, Solideth explains:

“3D printing expedites delivery of models and prototypes. Used in lieu of, or in conjunction with, conventional manufacturing practices, 3D printing may reduce lead times significantly. Additionally, additive manufacturing proves to be an efficient process with little demands in terms of time or effort on the front end of the process.

However, it yields parts with somewhat different physical characteristics and design constraints than those parts made using traditional manufacturing processes.

When seeking to evaluate product design with prototypes produced using the same methods as those for production, there are suppliers that specialise in rapid manufacturing using conventional methods, such as CNC machining and injection moulding. Although the manufacturing process is unchanged, process optimisation through automation leads to much shorter lead times. For example, an order of 500 injection-moulded prototypes, which can take months to deliver, can be made available in 7 to 10 days using Protolabs’ rapid injection moulding services.”

From a logistical point of view, 3D printing is seen as a turnover’s accelerator for both industrial manufacturers and to a certain extent, industrial 3D printing service providers.

On the start-ups side

A wide range of emerging start-ups created their business models around on-demand production of 3D printed products. 3D printed consumer products that stand out from the crowd often include eyewear. October 71 and King Children are a few examples of companies that have based their services on on-demand production of 3D printed glasses.

Given the start-ups environment, it is hard to confirm whether the removal of supply chain barriers and the integration of 3D printing on demand contribute to a significant revenue. Indeed, even though their production costs are reduced, the reality is that they do not yet benefit from the brand awareness of famous brands, and their investments will be made elsewhere, in communication for instance.

What about the supply chain and logistics (SCL) specialists now? Has the advent of 3D printing been a hurdle in their activities?

Supply Chain & Logistics companies and 3D printing

In a research carried out by Georgia Institute of Technology, researchers point out that “since the 1980s, computer technology has advanced at such a phenomenal rate that it is currently far ahead of the ability of the supply and logistics field to adequately utilize the new technologies.”

While 3D printing is disrupting supply chain management, there is every reason to believe that SCL companies are the key stakeholders that will suffer from this change. However, reality shows that some of them have turned what seemed to be “lemons into lemonade”.

UPS, for instance, a leader in supply chain services, expanded its offering by launching on-demand 3D printing manufacturing network, through its subsidiary UPS Capital.

The service was launched in 2016, as a tailor-made supply chain management solution. The solution links its global logistics network with 3D printers at the UPS Store® in more than 60 locations around the U.S. and Fast Radius’ On Demand Production Platform™ and 3D printing factory in Louisville, KY. The integration into one additive manufacturing and logistics solution this summer will make 3D printing accessible to more potential users, enabling them to realize the convenience and cost-savings this technology offers.

Fur ther strengthening UPS’s distributed, on-demand manufacturing offering, SAP today announced an agreement with UPS to create an end-to-end industrial solution. SAP’s extended supply chain solutions will be integrated with UPS’s on-demand manufacturing solution and global logistics network to simplify the industrial manufacturing process from digitalization, certification, order-to-manufacturing and delivery.

Customers will visit the Fast Radius website (formerly CloudDDM) to place their 3D printing orders, which will be directed to the optimal manufacturing or The UPS Store location based on speed, geography, and the product quality the customer requires. Orders can be shipped as early as same day. While participating The UPS Store locations are all in the U.S., companies globally could utilize the network and place orders.

By integrating SAP’s extended supply chain software with the UPS additive manufacturing solution and logistics network, manufacturing companies of all sizes will be able to access on-demand industrial manufacturing with the touch of a button. SAP customers will be able to digitize and simplify the production part approval process through SAP and their orders can be seamlessly routed to UPS for production and delivery.

Last year, Fedex followed the move with the creation of a new company, FedEx Forward Depots, whose focus is 3D printing. FedEx Forward Depots will handle Critical Inventory and Service Parts Logistics, 3D Printing, Repair Center and the FedEx Packaging Lab.

Fedex did not provide further information about the way it intends to manage this new service. However, unlike UPS, its first idea was to “go local” with manufacturing.

Nevertheless, while looking at a global scale, we will note that a digital file can be created in one place, prototype in another continent a few hours later, and sent within the next day to another geographical area. Here again, supply chain plays a key role but one might also consider a new form of storage.

The cloud, a new form of storage?

Supply Chain & Logistics companies have thousands of warehouses around the world where manufacturers stock parts for maintenance. The truth is that, a very few numbers of these parts are actually used; moreover, most of the time, they are completely forgotten.

With additive manufacturing, manufacturers do not only save time but also space, because, it all starts with a digital file.

Companies like Onshape are reinventing manufac turing processes by facilitating the access to digital files wherever the country of their clients is. Onshape has developed a 3D cloud CAD platform to accelerate collaboration and communication with its customers.

“On a daily basis, there are companies all over the world – throughout Asia, Europe and the United States – contacting us for printing small parts with our nanoArch® printers,” says BMF’s CEO, Dr. Xiaoning He. “Before using Onshape, we had to email CAD files back and forth with our customers. But now we can have our team in China and our customers overseas work together on the same model at the same time. It has really improved our efficiency and speed, and Onshape is the only CAD system that can deliver this capability.”

BMF Material Technology specializes in micro/nano-scale 3D printing that enables to manufacture extremely small and complex parts such as connectors, endoscopes, cardiac stents and tiny springs.

According to Dr. Xiaoning He, the platform speeds up the learning curve for their customers. Indeed, the CAD system combines advanced 3D modeling tools with design data management in a secure cloud workspace. Its unique database architecture eliminates the security risk and version control problems created by uncontrolled file copies – because only one master copy of the CAD data is stored in the cloud, accessible only by different levels of permissions (edit, view-only, commenting, etc.).

Furthermore, Protolabs’ Sales Manager explained that, thanks to their web-based business model, they have quoted 1 million unique part numbers for moulded parts globally and served 37000 unique product developers in 2017. So, in this context, one could consider the cloud as a new form of storage if “the end user’s technology, knowhow, and access to materials enable it and also provided the producer is happy to give access to his parts cad file.”

In a nutshell…

To sum up, the use of 3D printing has indeed disrupted supply chain management and each stakeholder has managed to take advantage of it. If manufacturers and providers of industrial 3D printing services are able to maintain on-demand production at a «glocalized» level (global + local), it is probably due to the cloud, their “new form of storage”.

On the other hand, even though they are aware of the impact of 3D printing on the supply chain, only a few SCL companies have been able to manage this risk. In the end, let us not forget that a wide range of products are still produced using traditional manufacturing methods.

To conclude, even though this article only features the industrials’ point of view, it should be noted that with the maker movement, and the popularization of 3D printing, a few number of people manufacture their own daily products. Therefore, they no longer need the supply chain, except for their equipment, and this remains to be verified.