Polymaker, the specialist of high-quality functional materials for 3D printing will collaborate with with INTAMSYS, a manufacturer of 3D printers in PEEK 3D printing.

For the producer of quality materials, this collaboration represents the first successful case of Printer Manufacturers Partnership Program (PMPP). Through this partnership, the companies’ goal is to provide better solutions to industrial customers via 3D printers and materials.

A close look at the market

It should be noticed that, the more the market of extrusion-based (e.g. FDM/FFF) 3D printing is growing, the more companies are becoming increasingly focused on one or two key technological areas to build their core expertise and strength.

INTAMSYS and Polymaker illustrate this fact

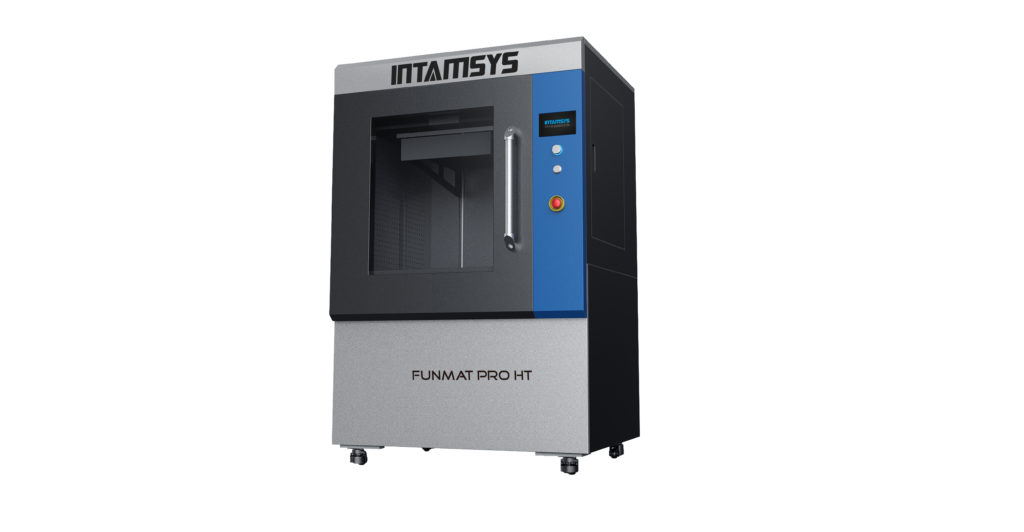

INTAMSYS specializes in producing reliable, industrial-grade 3D printers with high temperature capabilities.

As for Polymaker, the company dedicates to developing high-performance and functional materials for a wide range of industrial applications. This specialization will undoubtedly accelerate technological advancement.

However, this does not change the fact that professionals are still looking for the perfect and complete fabrication solution.

The integration between materials and machines.

To address this issue, the two companies look at the integration between materials and machines. The truth is that, as FDM/FFF 3D printing is increasingly part of functional prototyping and small-scale manufacturing, users need the perfect combination between machines and materials; hence Polymaker’s proposition of using the PMPP.

Printer Manufacturers Partnership Program (PMPP) is designed to be a collaboration platform between Polymaker and 3D printer manufacturers, with the aim of delivering the most accurate user solutions by integrating advanced materials and 3D printers.

The key elements of PMPP involve custom development of materials for the printers, extensive testing to optimize the printing profiles as well as to obtain the mechanical/physical data matrix, and creation of technical documents for professional users.

Furthermore, the program enables both companies to respond more quickly and efficiently to customers’ needs, which are quite diverse from one industry to another and often involve co-development in both machinery and materials.

The benefits of the program for each company

“As a materials supplier, we can only provide part of the solution; by integrating printer and materials we can provide more accurate data and full solutions to industrial customers.” – Dr. Xiaofan Luo, CEO of Polymaker.

Under PMPP, the engineers from Polymaker and INTAMSYS will produce together optimized material profiles, detailed technical data sheets and documents, as well as industry-specific solutions. Since INTAMSYS’ printers are equipped with active heating build chambers and high-temperature extruders, they are perfectly appropriate for engineering plastics such as polycarbonate, Nylon, or even PEEK. Polymaker could therefore produce parts with superior and more isotropic mechanical properties

Moreover, INTAMSYS will launch 4 Polymaker Industrial™ materials with plans to add more materials in the future.

Thanks to the program, INTAMSYS will have access to the entire Polymaker Industrial™ portfolio, which currently consists of over 20 different grades of engineering plastics as well as support materials.

Polymaker on its side, will develop the value of its materials by making them available to INTAMSYS’ customers.

It is definitely a win-win partnership for both companies.

For further information about 3D Printing, follow us on our social networks and subscribe to our newsletter!