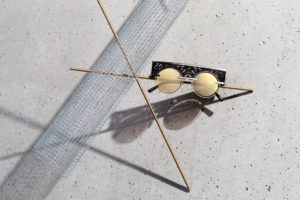

Materialise partners with eyewear leader Safilo for the new OXYDO SS 2017 collection, featuring a capsule collection of 3D-printed frames that turn eyewear into wearable sculptures. The new OXYDO Capsule Collection reflects the intention to demonstrate not only what Additive Manufacturing is capable of today but above all where it could lead the eyewear industry tomorrow.

Indeed, 3D Printing can produce organic and complex geometric parts on the one hand, on the other hand lightweight designs. The eyewear industry has taken advantage of such a competitive feature to create frames that use less material and increase the wearer’s comfort.

New York-based artist Francis Bitonti, who collaborated with OXYDO for design, says, “We focused on leveraging the capabilities of 3D Printing to produce very fine ornamentation while keeping a very minimal silhouette. We were interested in how the next generation of ornamentation might look.”

New York-based artist Francis Bitonti, who collaborated with OXYDO for design, says, “We focused on leveraging the capabilities of 3D Printing to produce very fine ornamentation while keeping a very minimal silhouette. We were interested in how the next generation of ornamentation might look.”

OXYDO Capsule Collection 2017 offers a disruptive, contemporary and sophisticated interpretation of the Italian fashion aesthetic, combining the classic shapes of round and cat-eye styles with ultra-modern silhouettes achievable only through 3D Printing. The 3D-printed structures that surround each of the frames are produced at Materialise’s Certified Additive Manufacturing facility, which houses machines dedicated to eyewear production. After manufacturing in Polyamide 12, the wearable sculptures are given the multi-step Materialise Luxura post-production treatment to enhance their performance and aesthetic.

“It is always our goal at Materialise to not only meet industry standards but to raise them. With Safilo, and their leadership in the eyewear industry, we have found a partner that values this goal equally,” says Alireza Parandian, head of wearables projects at Materialise. “The eyewear industry and Additive Manufacturing have built a symbiotic relationship, where each helps the other raise its standards and challenge expectations constantly. I’m looking forward to where this partnership leads next.”

“It is always our goal at Materialise to not only meet industry standards but to raise them. With Safilo, and their leadership in the eyewear industry, we have found a partner that values this goal equally,” says Alireza Parandian, head of wearables projects at Materialise. “The eyewear industry and Additive Manufacturing have built a symbiotic relationship, where each helps the other raise its standards and challenge expectations constantly. I’m looking forward to where this partnership leads next.”

//pagead2.googlesyndication.com/pagead/js/adsbygoogle.js

(adsbygoogle = window.adsbygoogle || []).push({});