The success of global B2C online marketplaces like Alibaba.com or DHGate has somehow led to the proliferation of multiple online manufacturing marketplaces across industrial sectors. While many of them address the needs of various product and service categories, it takes some sharpened strategy and business model to have a tremendous impact on the global manufacturing arena in its whole. Xometry is one of those companies that is playing in a different league as it services many countries in cross-border ordering and trading, including European and North American countries.

Founded in 2013 in the US, the company champions Manufacturing as a Service (MaaS) with a platform that hosts a network of machine shops and 3D printing service bureaus across the world, thus enabling customers in a wide range of vertical industries to produce parts on-demand.

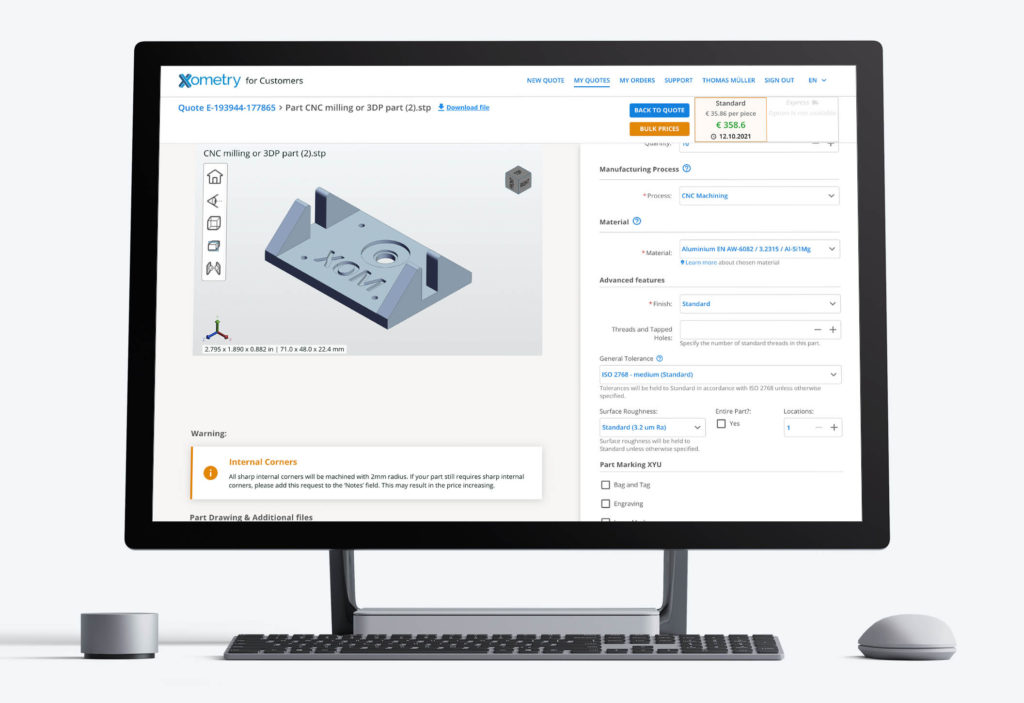

“The system is pretty simple: clients need to source their parts, we have the capacity and the access to a large network of carefully vetted providers who can take upon the clients’ projects. The clients/users can upload their CAD files on the online platform, choose between a large choice of manufacturing technologies (for example, in Europe we currently have 14 technologies available), materials and finishing options, get an instant quote and then order their parts. Once the order is done, we match the project with the most qualified and suitable manufacturing partner. At the same time Xometry takes care of the logistics, communication and quality control”, Dmitry Kafidov, Managing Director at Xometry Europe, told 3D ADEPT Media.

What makes Xometry’s platform work so brilliantly is the use of AI and machine learning within its systems. Those technologies allow for the interpretation of 3D files and help to get pricing right away for multiple technologies – instead of waiting for an RFQ.

Furthermore, the ability to combine a large spectrum of production capacities across Additive Manufacturing (AM) and conventional manufacturing categories is certainly the biggest strength of the company. Its portfolio of AM technologies include processes such as FDM, MJF, SLS, SLA, DMLS, Carbon DLS, Polyjet while its portfolio of more traditional processes includes CNC machining, sheet metal, injection moulding and die casting – technologies in a nutshell, that can process both metal and plastic materials.

“No matter whether the project is a prototype or the serial production of parts, we have the capacity to source it and produce it within a short amount of time”, Kafidov adds. And yes, before you ask, “the proportion of parts produced via traditional processes has always been higher, but the number of orders [they] receive for additively manufactured parts has been growing pretty fast over the past months and years.”

Here is the thing, the market is continuously growing and new companies keep emerging. So, how do we maintain growth in such a competitive market? Most importantly, how do we foster deeper, more profitable customer relationships?

From US to Europe and beyond…

The company may have been founded in 2013 but it is in 2017 that the company started to turn stealth mode off. With over $118 million dollars raised from major investors such as BMW i Ventures, Robert Bosch Venture Capital, Dell Technologies Capital, and GE Ventures, Xometry has dedicated its activities during the first years to solidifying its footprint in the US market.

These investments helped to launch injection moulding services and new software features, and helped to add other AM production capacities. Additions to the marketing and production teams as well as to the board of directors and strategic partnerships with key companies have been made to support this growth. December 2019 marked another turning point when it acquired Shift, Europe’s largest on-demand manufacturing marketplace.

Shift that became Xometry Europe facilitated the company’s international expansion into 12 new countries at first. After the first year of the company’s activities, Xometry Europe’s monthly customer base had grown over tenfold compared to the previous year. Other key highlights on the European market included the official recognition of its quality management with ISO 9001:2015 certification, the company’s initial public offering, and from a manufacturing standpoint, the availability of instant quoting on Autodesk Fusion 360, the free delivery of 3D printed parts as well as the launch of die casting services.

According to the company’s Managing Director, “working with Xometry Europe gives one access to the production capacity of over 2000 vetted manufacturing workshops from more than 25 European countries. If we think worldwide, Xometry works in collaboration with more than 5000 manufacturing workshops.”

Being able to grow at such a fast pace in a MaaS business model lies in the ability to understand the two sides of the same coin: the supplier and the customer.

The Supplier vs the Customer

On the one hand, there is a smart utilization of production capacity as machines that would otherwise sit idle are leveraged to meet demand for parts from other companies. Moreover, with efficient localization comes faster speed of delivery. This means that for equal price and premium quality, each part is manufactured locally, near the customer.

On the other hand, Xometry continuously invests extra miles to help customers that are using its platform to source parts. In addition to free shipment on 3D printing orders, customers benefit from a manual check for the feasibility of the design, a custom support for each order as well as online resources that improve their learning curve on manufacturing processes, design tips, materials, etc.

Whether you are on the supplier’s side or the customer’s side, there is definitely room to make your manufacturing environment more flexible, efficient and responsive.

Innovation and outlooks for 2022

With the Covid-19 pandemic, the benefits of MaaS have been validated and expedited across a wide range of vertical industries. The vertical sector that benefitted the most from it is the medical field. Xometry for instance, helped one client to produce millions of masks to face the pandemic. It also helped an engineer to manufacture parts for a device that can destroy viruses in the air.

“We saw an increase interest towards on-demand manufacturing overall. It boosted our development as people were looking for a more reliable and flexible supply chain”, the expert outlines.

Like most technology companies, to move forward and remain on top of its game, the company continuously invests in R&D – in this specific case, in the form of product development.

“The main investments are done on our platform and algorithm, the Instant Quoting Engine (IQE) because this is what our business is based on. And it did bring benefits to the company and helped us to expand. In 2022, Xometry will keep adding new technologies and materials to our offer as well as continuing further global expansion, for example, in the Asian region”, Kafidov concludes.

This content has been created in partnership with Xometry.