In a joint development project initiated two years ago, a cross-functional Ford-ExOne team has qualified one of the most commonly used aluminum alloys in the world.

It’s been two decades that both companies have strong commercial relationships that led to the acquisition of several ExOne industrial sand 3D printers by Ford which support the production of sand molds and cores for metal casting.

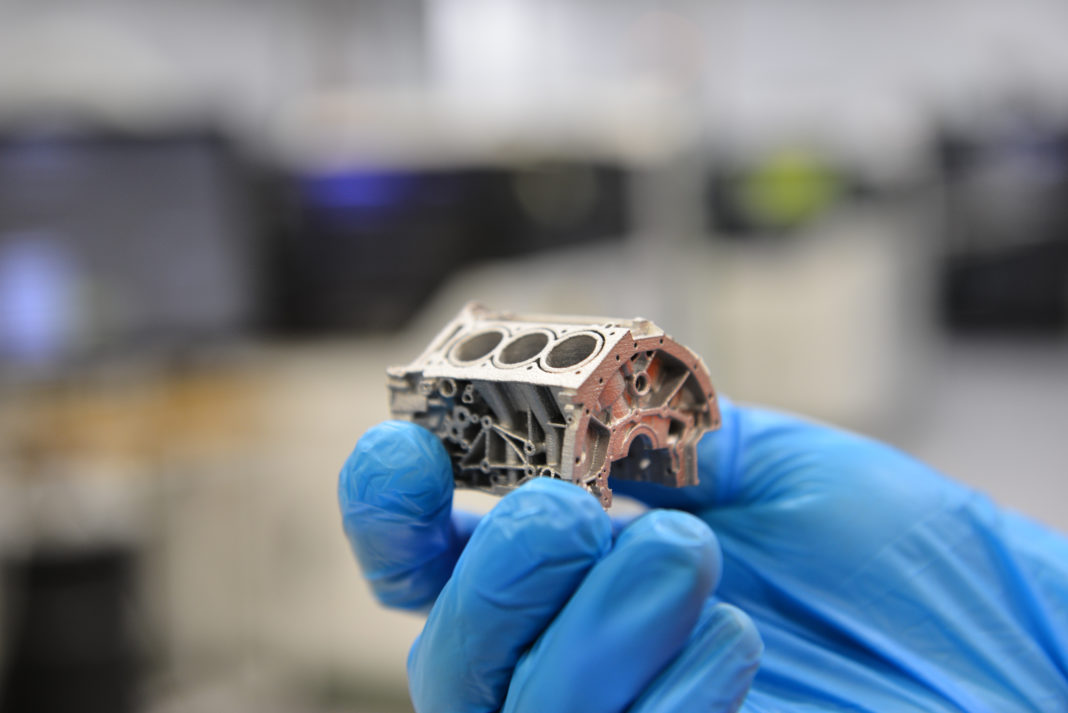

As part of a project co-funded by both companies, a team of expertshas developed a patent-pending process for binder jet 3D printing and sintering of aluminum that delivers properties comparable to die casting.

According to experts, some aluminum alloys can be 3D printed today using lasers, but the process would be much slower than this newly developed process.

Ford aims to enhance efficiency by producing complex parts uniquely designed for additive manufacturing, which enables size and weight reductions, part consolidation, and performance improvements.

“This is a breakthrough in making 3D printed and sintered parts for the auto industry,” said Harold Sears, Ford technical leader for additive manufacturing. “While the 3D-printing process is very different than stamping body panels, we understand the behavior of aluminum better today, as well as its value in light-weighting vehicles. High-speed aluminum 3D printing paves the way for other opportunities that we’re just now starting to take a look at because of the ability to do complex parts with aluminum that previously weren’t possible. It’s really opening doors for other opportunities.”

How does the new process work?

As you may know, in a binder jetting process, metal powder is moistened for a specific purpose by a liquid binding agent, binding it together. The binder is applied to the powder, before the addition of the next layer.

Read more about the potential & limitations of binder jetting and MIM.

The patent-pending process developed by Ford and ExOne requires the use of a digital file to quickly inkjet a binder into a bed of powder particles such as metal, sand, or ceramic to create a solid part, one thin layer at a time. ExOne explains in a press communication that at the end of the fabrication, the final bound metal part must be sintered in a furnace to fuse the particles together into a solid object.

The post-processing stage which is heating helps strengthen the aluminium powder which keeps its material properties. Given the requirements and complexity of sintering stainless steel, being able to achieve high densities greater than 99 percent is a huge milestone for the entire industry.

“Developing a fast, affordable, and easy way to 3D print aluminum with traditional material properties is a critical step toward light-weighting more products and delivering a more sustainable future,” said John Hartner, ExOne CEO. “Our world-class engineers and scientists are focused on solving the toughest problems with 3D printing technology, and this achievement is a real win for all of us.”

Remember, you can post job opportunities in the AM Industry on 3D ADEPT Media free of charge or look for a job via our job board. Make sure to follow us on our social networks and subscribe to our weekly newsletter : Facebook, Twitter, LinkedIn & Instagram ! If you want to be featured in the next issue of our digital magazine or if you hear a story that needs to be heard, make sure to send it to contact@3dadept.com