At Formnext, the company showcases highly connective software solutions for all processes in additive manufacturing – from data preparation to quality control

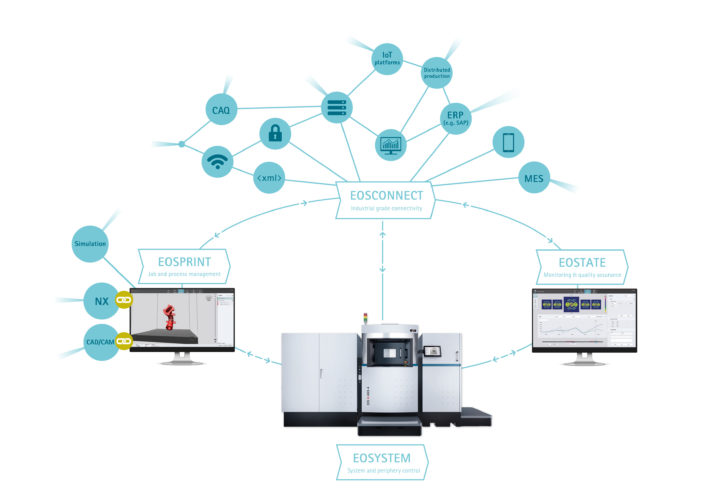

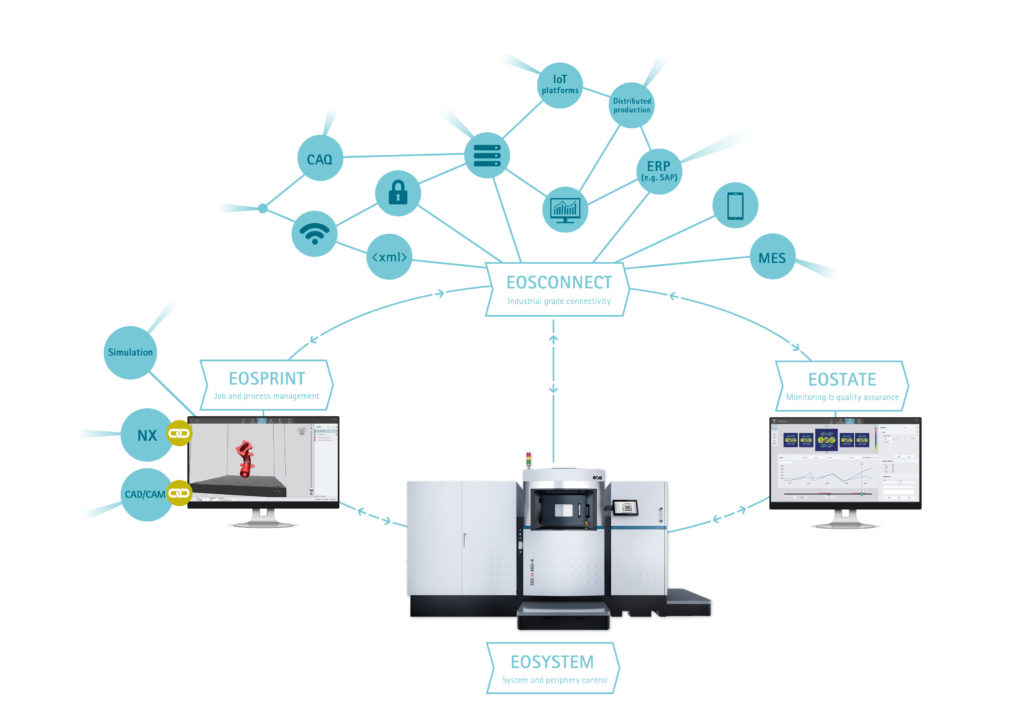

The specialist of industrial AM unveils the latest versions of EOSPRINT 2 for job and process management, the process monitoring suite EOSTATE, as well as EOSCONNECT which provides industrial grade connectivity.

The company aims to provide companies the necessary tools to seamlessly integrate 3D printing into their manufacturing process.

EOSPRINT 2

EOSPRINT 2

EOSPRINT 2 is an intuitive, open and productive CAM tool that allows businesses to optimize CAD data for EOS systems. Together with data preparation software like SIEMENS NX™ or Magics, it offers an extensive AM CAM environment for engineers who want to fully leverage the benefits of additive manufacturing with production-ready design.

Customers integrating AM and post-process machining can profit from the reference point calibration feature. The feature is essential to set the same zero point across different machine types, such as milling and turning machines and industrial 3D printing.

Furthermore, EOSPRINT offers expert functionalities to enhance material and process development with the DoE (Design of Experiments) Set-up feature.

Process monitoring suite – EOSTATE

EOSTATE is an automated and intelligent multi monitoring suite that enables customers to conduct a real-time quality assurance of all production and quality relevant data.

It is composed of four different monitoring tools: System, PowderBed, MeltPool and Exposure OT (optical tomography).

EOSCONNECT – Industrial grade connectivity

This gate opener enables to gain flexibility and increase productivity. Machine and production data can be gathered and made available in near real-time. EOS even offers an intuitive app to visualize the data in a dashboard. This is the next step towards a comprehensive and user-friendly machine park surveillance.

Its advantages include a seamless handover of production data for companies into their CAQ systems (Computer Aided Quality) for secure traceability, helping them to validate their processes for production.

Furthermore, they also can benefit from transparency with visualization and readout of real-time production KPIs.

For further information about 3D Printing, follow us on our social networks and subscribe to our newsletter!