Home =

powder handling - search results

If you're not happy with the results, please do another search

Volkmann and EOS now provide automated metal powder solutions for 3D printing

A new partnership signed between 3D printer manufacturer EOS GmbH, and metal powder conveying equipment manufacturer Volkmann GmbH led to the compatibility of Volkmann’s closed-loop and automated metal powder management systems with the EOS...

Key considerations to take into account for the production of 3D Printable stainless steel powders

There are a number of reasons why one can select stainless steel for additive manufacturing (AM) processes, including its superior corrosion, mechanical properties compared with other steel types (meaning that the component will last...

Assonic & Oerlikon partner to streamline Additive Manufacturing with a new powder preparation system

The last time we spoke about German machine manufacturer Assonic Dorstener Siebtechnik, the company was part of the AM Powder Plus network which aimed to deliver a range of solutions for highly automated parts...

Solukon releases a powder collection unit that should be used after the depowdering of metal 3D printed parts

With every step that surrounds the depowdering process, machine manufacturer Solukon is uniquely positioned to address the challenges of the main steps that precede or follow the depowdering phase. One of these challenges consists...

Uniformity Labs unveils multimodal UniJet™ SS17-4PH Stainless Steel Powder for Binder Jetting 3D Printing

Engineered materials company Uniformity Labs has qualified its ultra-low porosity 17-4PH stainless steel powder UniJet™ SS17-4PH for the Desktop Metal Production System™.

During the qualification on Desktop Metal’s Production System™, the physical and mechanical properties...

The must-have technical features in an automated powder removal system

With key examples on medical 3D printing.

Most of the time when we talk to an additive manufacturing user, one of the challenges that keeps coming back when using additive manufacturing is the post-processing stage...

Dressler Group on the importance of a “powder designer” for additive manufacturing & key questions related to the use & production of AM materials

Designing in additive manufacturing is almost always linked to the part an engineer will model with the right software tool. It’s right but there is more. Remember when we told you that the true...

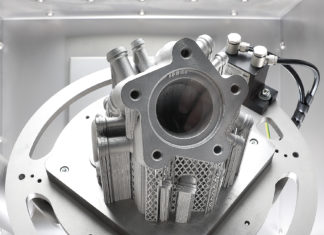

Solukon and Festo to explore how far they can push the level of automation for depowdering of 3D printed parts forward

Solukon and Festo joined forces in a development project to enhance efficiency when it comes to the depowdering of laser-melted metal parts. An intriguing announcement when one knows that Solukon’s proprietary Smart Powder Recuperation...

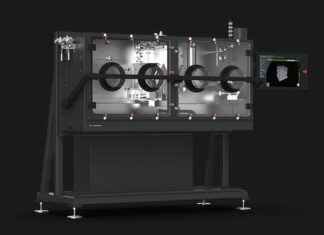

Inspired by ExOne and Crafted by Solukon? A new partnership leads to the X1DPS 160 depowdering station for ExOne’s binder jet 3D printer

ExOne and Solukon Maschinenbau GmbH work together on the development of a new depowdering station for binder jet 3D printing.

If you are a regular reader of 3D ADEPT Media, then those names should be...

Dry process air in additive manufacturing – a decisive factor for powder quality and production process

Whether additive manufacturing is utilized for prototyping or serial production – throughput times can often be significantly reduced. Furthermore, products that previously consisted of several mounted parts, can now be manufactured as a single...